Piezoelectric fan heat dissipating closed module

A piezoelectric fan, closed technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. Achieve the effect of simple structure, wide environmental adaptability and strong electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

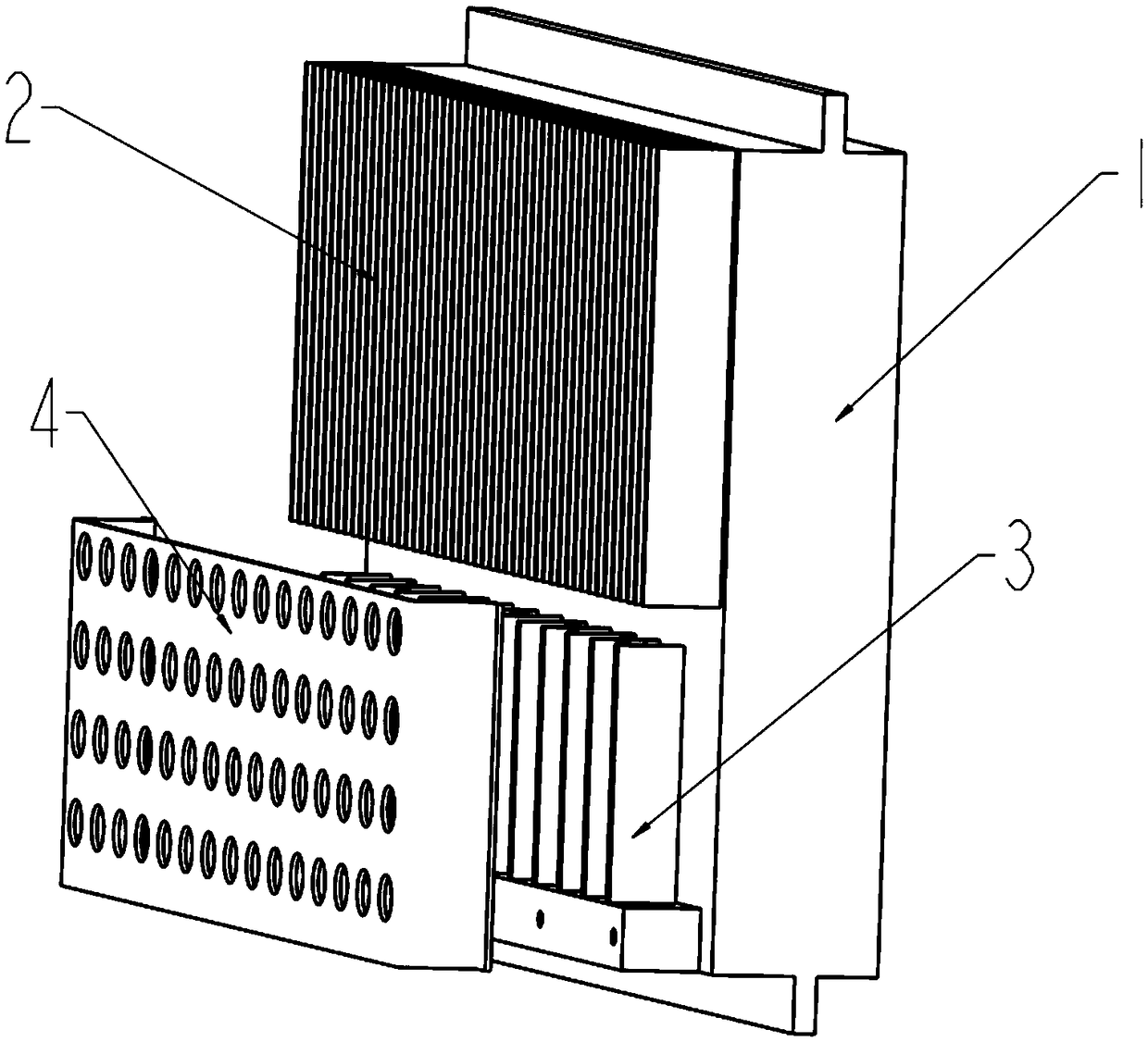

[0033] Such as figure 1 As shown, a piezoelectric fan heat dissipation closed module of the present invention includes,

[0034] Module 1, cooling fins 2 and piezoelectric fan 3. The cooling fins 2 are arranged on the cavity wall of the module 1, and the piezoelectric fan 3 is arranged below the cooling fins 2 to provide cooling airflow for the cooling fins 2.

[0035] In this embodiment, the heat dissipation fins 2 and the blades of the piezoelectric fan 3 are in a parallel structure, and the piezoelectric fan 3 uses the inverse piezoelectric effect of piezoelectric ceramics to drive the blades directly under the driving of an alternating electric field. Resonance is generated, and the high-speed and stable airflow is output from the blade end to the front to directly cool the parts that need heat dissipation.

[0036] In this embodiment, a temperature equalization device is provided in the base plate of the heat dissipation fin 2, which can be a VC equal temperature plate o...

Embodiment 2

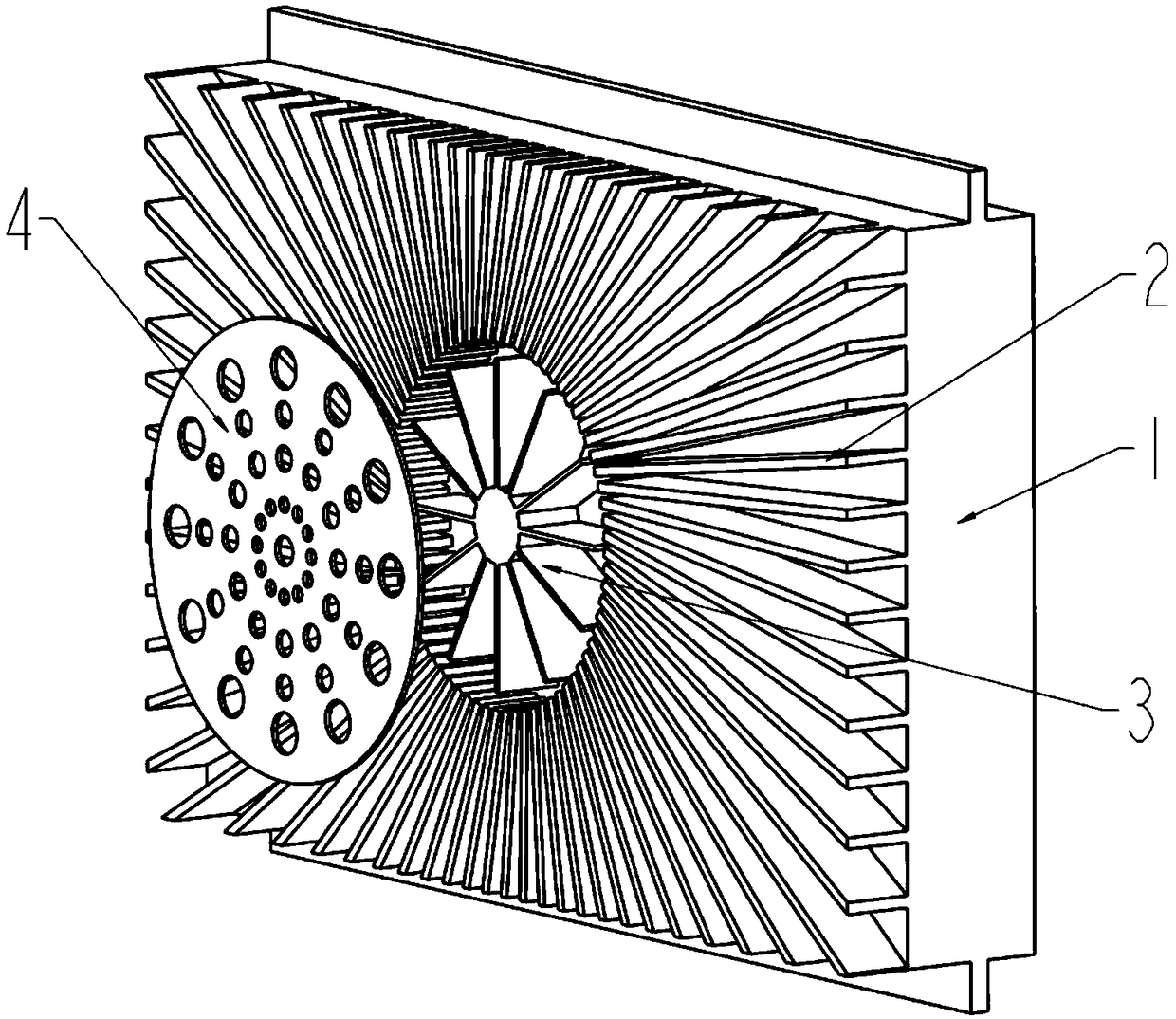

[0041] Such as figure 2 As shown, it is another embodiment of the piezoelectric fan cooling airtight module of the present invention, including a module 1, cooling fins 2 and a piezoelectric fan 3, and the cooling fins 2 are arranged on the cavity wall of the module 1, and implemented The difference from Example 1 is that in this embodiment, the cooling fins 2 are in a structure surrounded by sunflowers, the blades of the piezoelectric fan 3 are also in a structure surrounded by sunflowers, and the piezoelectric fan 3 is installed on the top of the cooling fins 2. at the center. The piezoelectric fan 3 utilizes the inverse piezoelectric effect of piezoelectric ceramics. Driven by an alternating electric field, the blades resonate, and output high-speed and stable airflow from the blade end to the surrounding cooling fins 2 . A protective cover plate 4 is provided on the outside of the piezoelectric fan 3, and an air inlet hole is provided on the cover plate 4.

[0042] Comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com