Membrane electrode and preparation method thereof

A technology of membrane electrodes and anodes, applied in battery electrodes, circuits, fuel cells, etc., can solve problems such as uneven dispersion of catalyst particles, achieve the effects of improving electrochemical performance, uniform and stable slurry, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention does not specifically limit the preparation method of the above catalyst slurry, and it is preferable to complete the preparation by an ultrasonic dispersion method, and the ultrasonic time is preferably 25 minutes.

[0066] Then, the prepared slurry is coated on the proton membrane with an electrostatic sprayer to form a membrane electrode.

[0067] The present invention also provides a method for preparing the above-mentioned membrane electrode, which includes the following steps:

[0068] The catalyst slurry is sprayed onto the surface of the proton exchange membrane by electrostatic spraying process.

[0069] In the present invention, an electrostatic sprayer is preferably used for spraying, and the temperature of the vacuum chuck is preferably 90-100°C. This temperature can prevent the secondary agglomeration of the dispersed resin monomer. At the same time, while ensuring battery performance, try to reduce the preparation temperature.

[0070] The ab...

Embodiment 1

[0076] The platinum-carbon catalyst (0.303g) containing 46.5wt% platinum was dispersed in a mixed solvent of 6mL deionized water and 12mL ethanol by ultrasound to form a uniform suspension. At the same time, 0.22g cobalt nitrate hexahydrate and 0.396g tetrabromide Octylammonium was dissolved in 12 mL of ethanol solvent to form a cobalt nitrate solution, and then the cobalt nitrate solution was added dropwise to the platinum carbon suspension solution to form a mixed solution, the mixed solution was stirred, and the mixed solution was mixed while maintaining stirring To form a uniform solution, adjust the pH to about 4 to make the mixed solution acidic, and then pass an inert gas (such as nitrogen, helium or argon) into the mixed solution to remove oxygen for more than 1 hour.

[0077] Add 0.4 mL of hydrazine hydrate to the deoxygenated mixture. After stirring for 24 hours, wash the solids alternately with deionized water and ethanol, filter until the pH of the filtrate is neutral,...

Embodiment 2

[0082] 1. Preparation of catalyst slurry

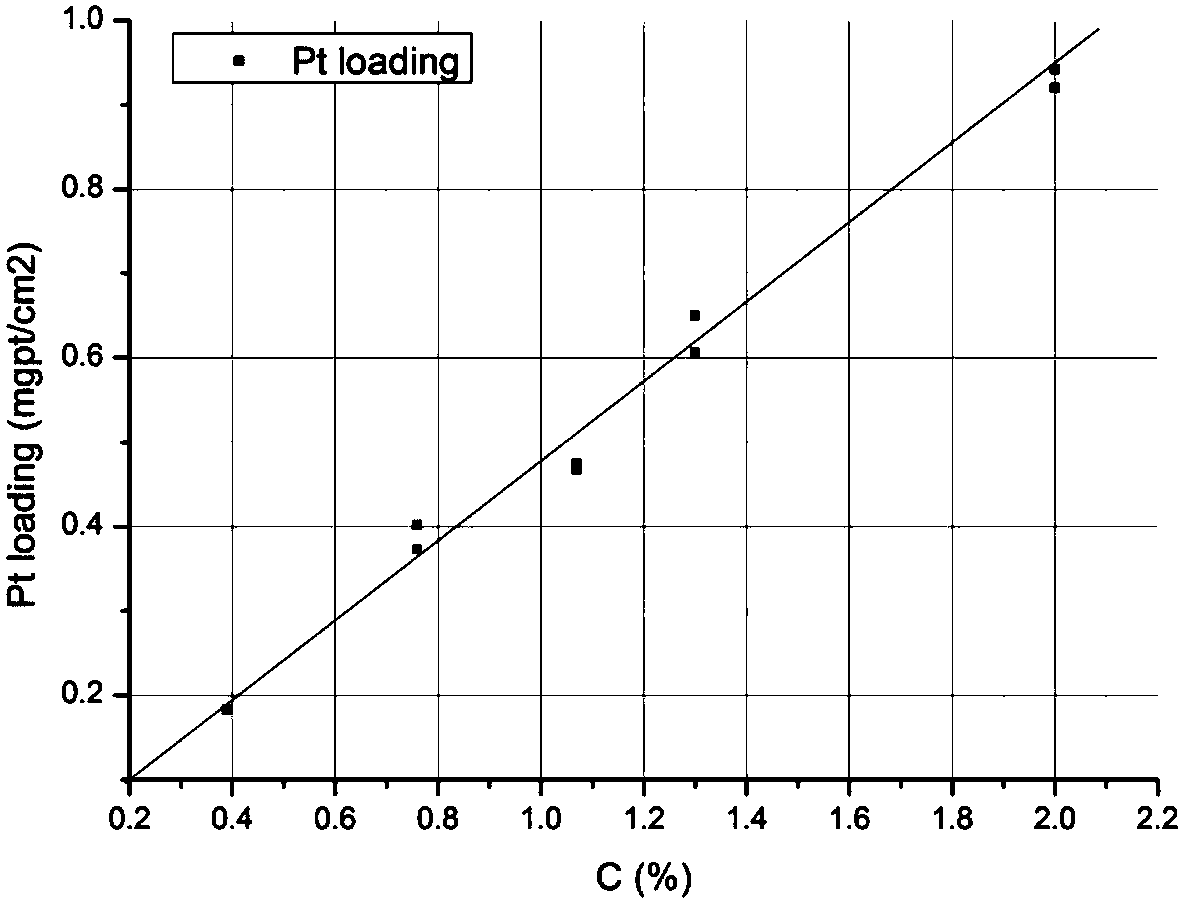

[0083] Take a certain amount of the PtCo / C catalyst prepared in Example 1, and add the catalyst, deionized water, Nafion solution, ethanol, isopropanol and dioxane in sequence. The mass ratio of the above 6 components is 1:5:4:49 : 21:5. Among them, I / C = 0.75, and carbon mass fraction = 0.65%. After mixing, ultrasonic stirring was performed for 25 min.

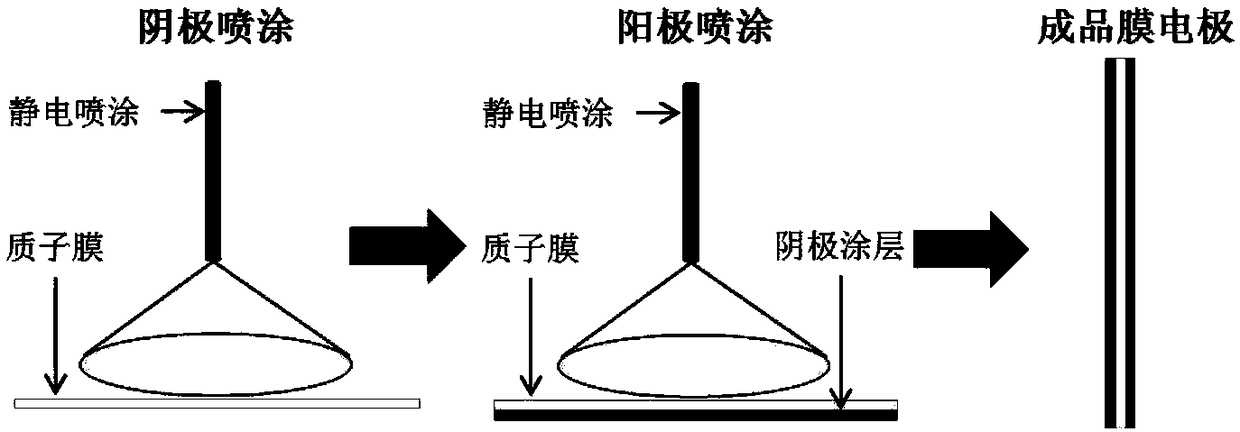

[0084] 2. Electrostatic spraying

[0085] Set the temperature of the vacuum chuck to 95°C, and place the proton exchange membrane on the vacuum chuck. Add the prepared slurry to the feed tank, adjust the parameters of the electrostatic sprayer, and control the Pt loading of the cathode catalyst layer at 0.3mg Pt / cm 2 , The anode Pt load is 0.1mg Pt / cm 2 .

[0086] See the specific spraying process image 3 Shown.

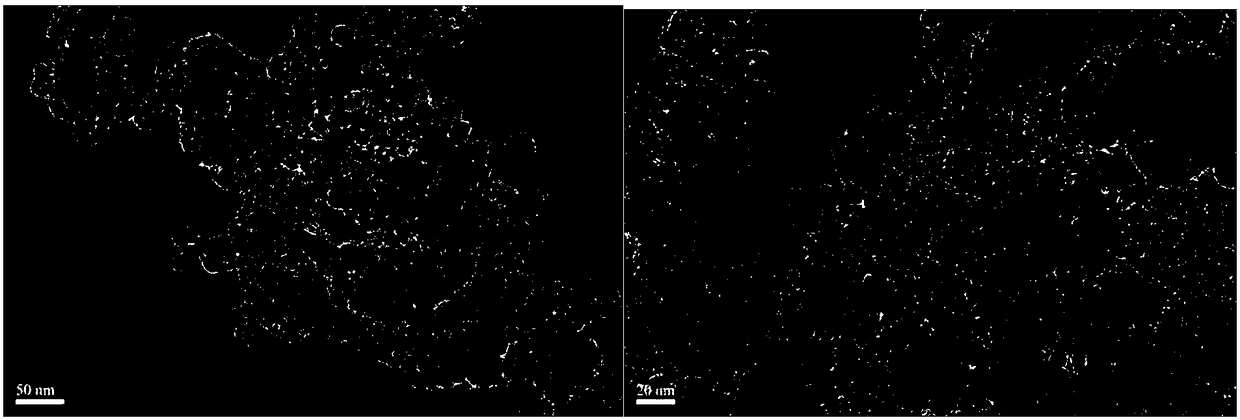

[0087] Figure 4 SEM image (perpendicular to the direction of the proton membrane) of the catalytic layer formed after spraying. by Figure 4 It can be seen that the resin mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com