Rotor pump shaft sealing device

A shaft seal, rotor pump technology, applied in pump components, rotary piston type/swing piston type pump components, machines/engines, etc., can solve problems such as affecting the service life of the rotor pump, affecting, not fundamentally eliminating the drawbacks, etc. , to avoid scratching the shaft surface, maintain service life, and achieve the effect of good service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

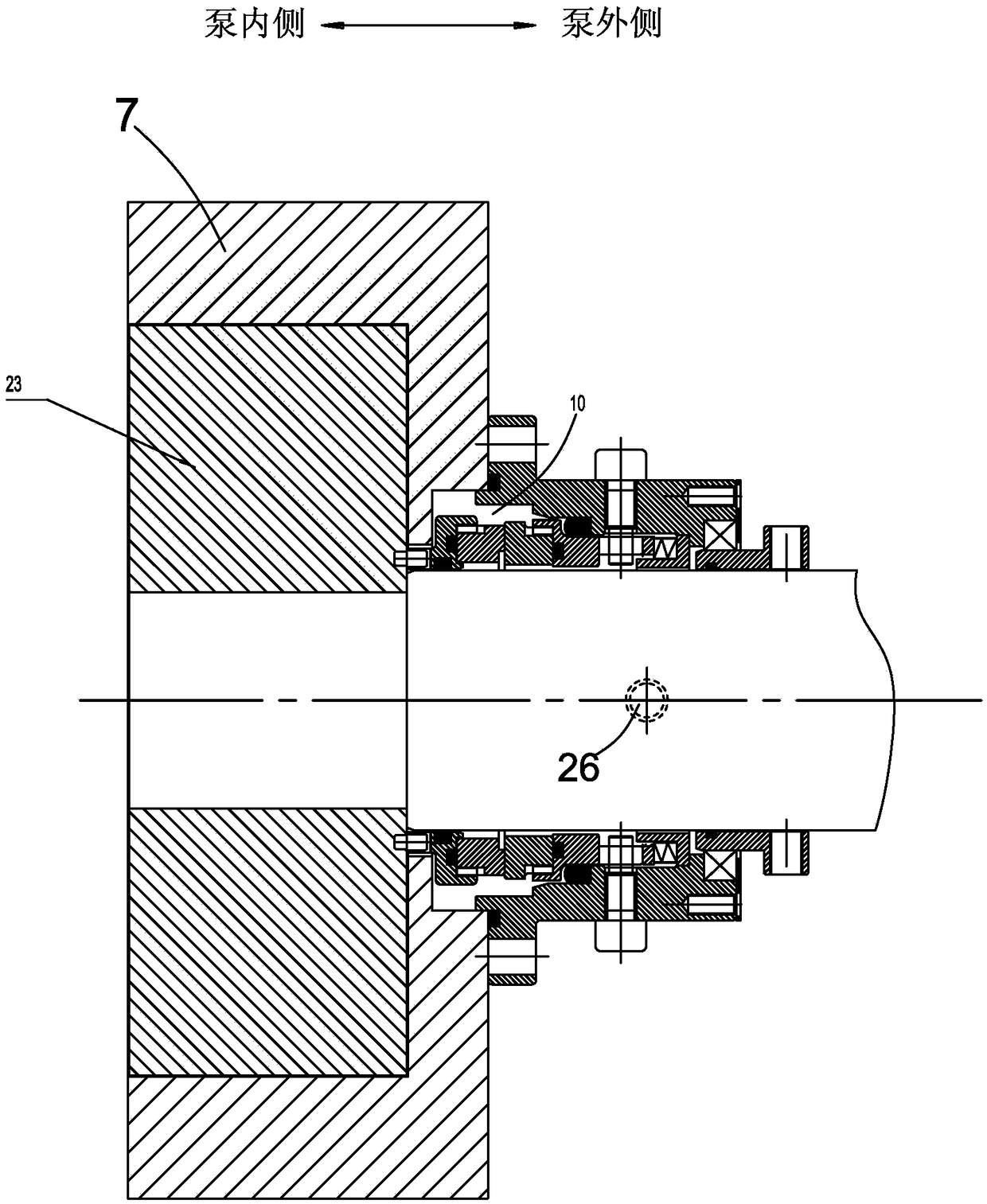

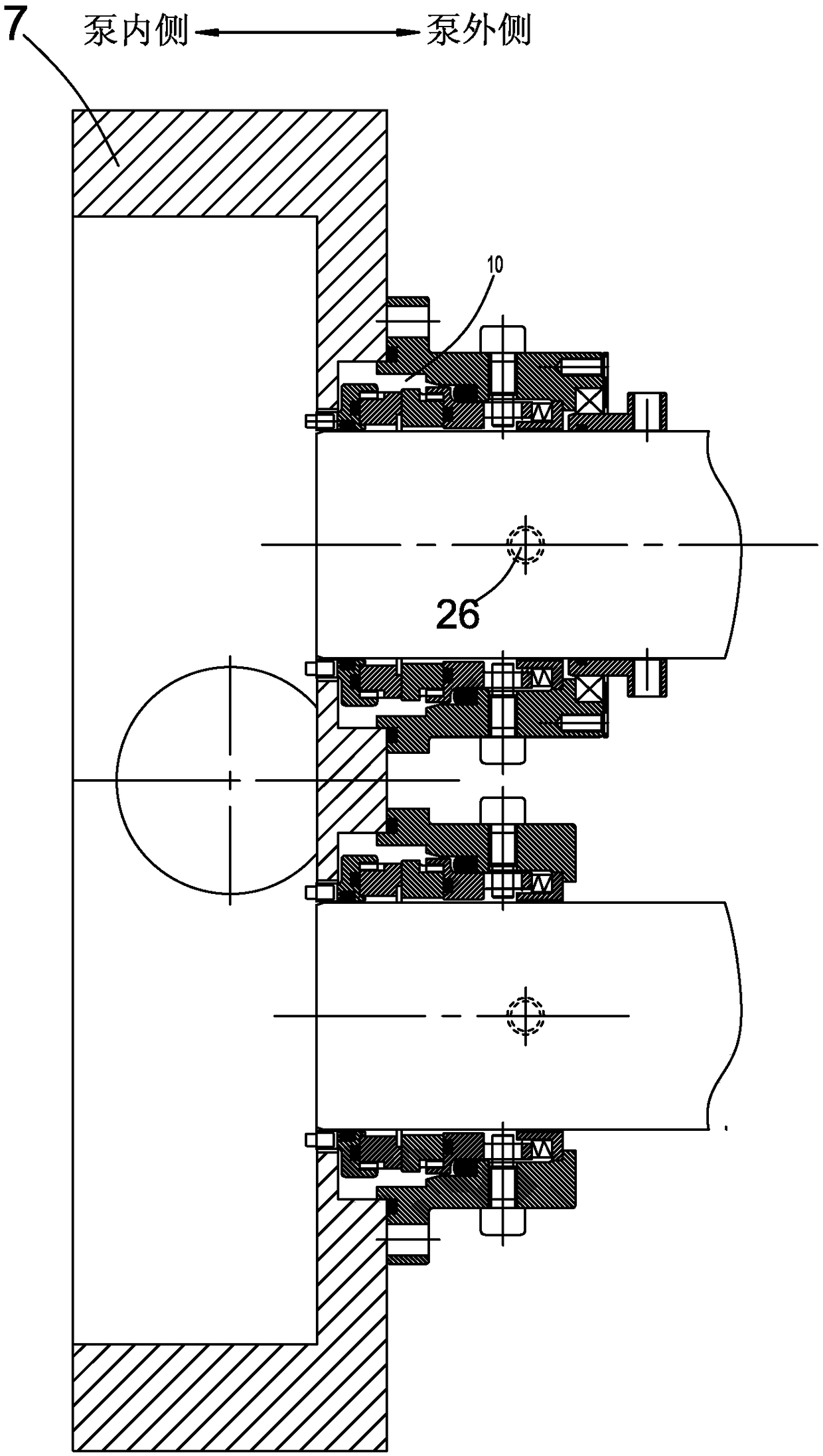

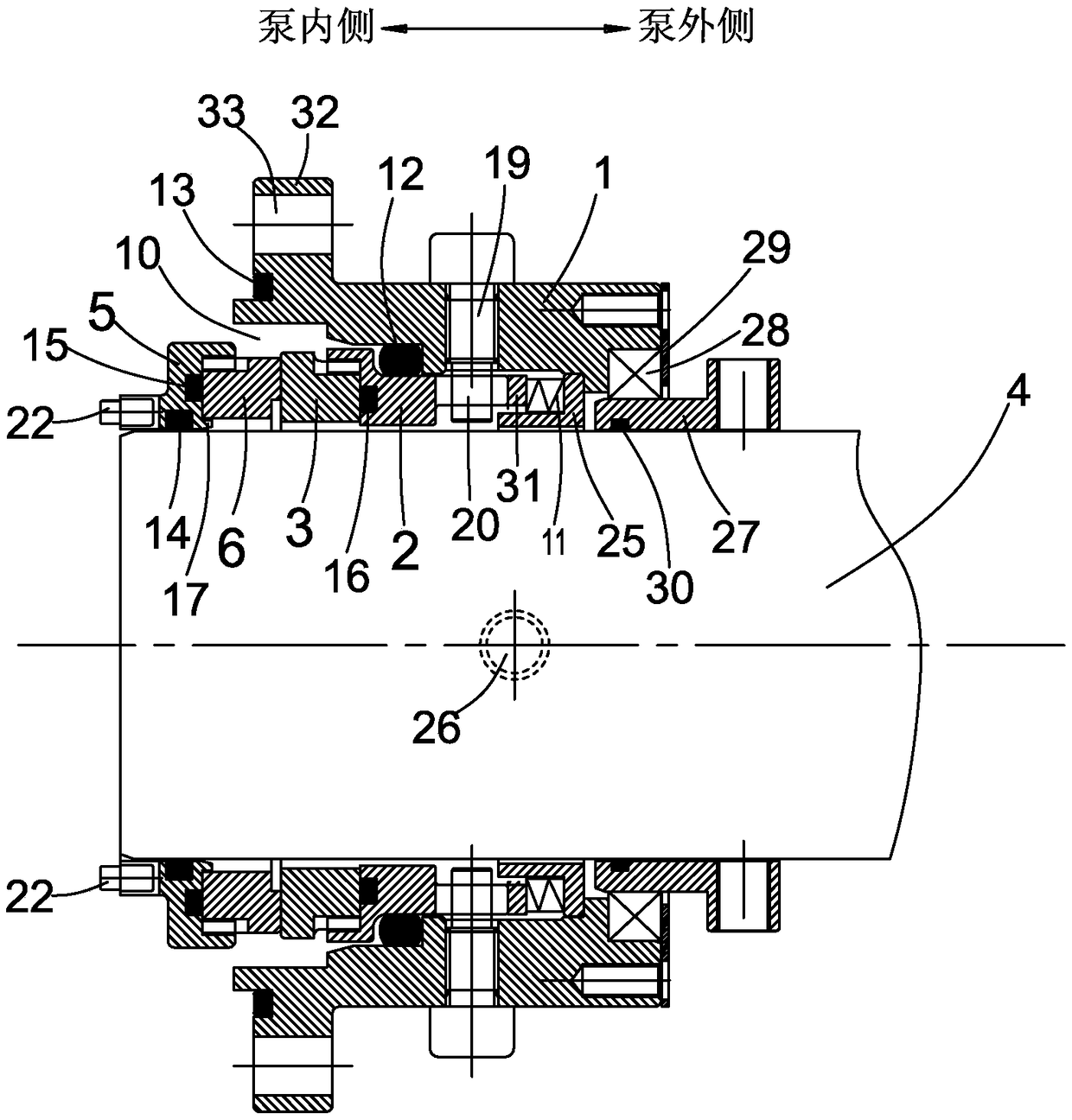

[0044] A rotary lobe pump, such as figure 1 , figure 2 As shown, the shaft 1 of the rotor pump is fixedly connected with the impeller 2 as the rotor, and the two impellers (23) as the interactive rotors are located in the pump body (7), and the two parallel shafts (4) output through the synchronous box are respectively connected with the The corresponding impeller (23) is fixedly connected. The shaft seal of the rotary pump, such as image 3 As shown, it includes the machine seal seat (1), the static ring seat (2), the static ring (3), the moving ring seat (5) rotating with the shaft (4) and the moving ring (6) driven by it, all set outside the shaft (4). Mechanical seal such as Figure 4 , Figure 5 As shown, the static ring seat is as Figure 10 , Figure 11 As shown, the static ring is as Figure 12 , Figure 13 As shown, the moving ring seat is as Image 6 , Figure 7 As shown, the moving ring is as Figure 8 , Figure 9 shown. The mechanical seal seat (1) i...

Embodiment 2

[0053] Such as Figure 18 As shown, the difference between the second embodiment and the first embodiment is that there is no cooling liquid circulation system outside the mechanical seal seat (1). In this way, the circumferential wall of the machine seal seat (1) does not need to offer a cooling liquid inlet and outlet hole (26), nor does it need to arrange a cooling liquid anti-leakage mechanism. Others follow the scheme of Embodiment 1. When the shaft sealing device of the rotor pump in the second embodiment is assembled, the relevant parts of the shaft sealing device can be directly installed on the outside of the pump body (7) in sequence.

Embodiment 3

[0055] Such as Figure 19 As shown, the difference between the third embodiment and the first embodiment is that the material section and the sealing section of the machine seal seat (1) are separately set as the machine seal front seat (1A) and the machine seal rear seat (1B), and the machine seal seat (1) 1) It is an assembly composed of the front seat of the machine seal (1A) and the back seat of the machine seal (1B). The flange end (32) is arranged on the inner side of the pump of the front seat of the machine seal (1A), and along the circumference of the flange end (32) A plurality of connection holes (33) are provided, and the inner cavity of the pump body (7) is provided with a flange installation cavity, and the flange end (32) of the front seat of the mechanical seal (1A) is embedded in the flange installation cavity, and the inner cavity of the pump body (7) The cavity is fixedly connected to the machine seal seat (1) and the pump body (7) via multiple bolts; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com