Anti-deformation aviation light guide plate inlaying structure and inlaying process thereof

A mosaic structure and light guide plate technology, which is applied in the aviation field, can solve the problems of affecting the service life, breakage of the light guide plate, and the thermal expansion of the light guide plate, so as to achieve a good service life and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

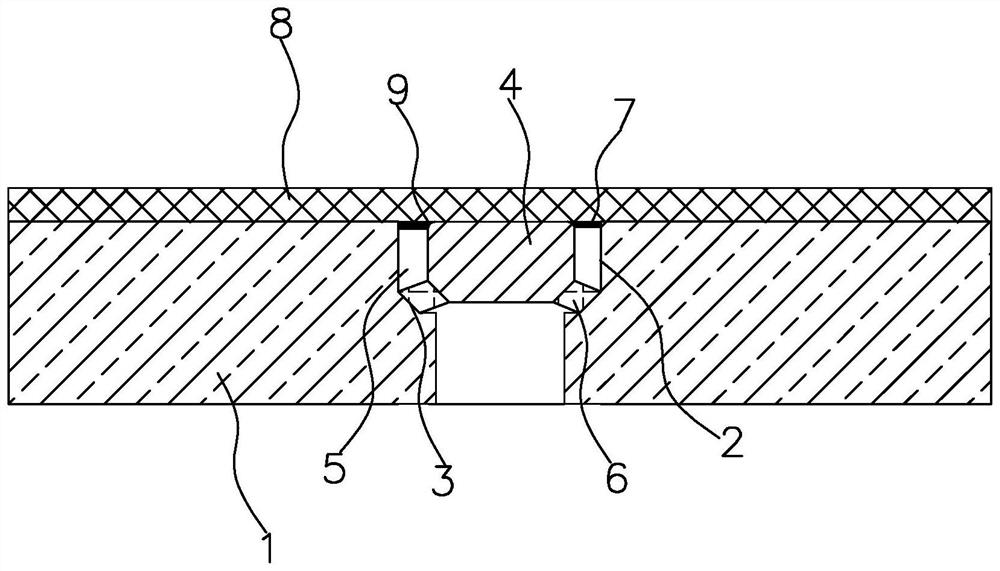

[0032] An anti-deformation aviation light guide plate mosaic structure, such as figure 1 As shown, it includes: a supporting substrate 1, a accommodating bearing port 2 is opened on the supporting substrate 1, and an oblique opening 3 is provided at the bottom edge of the accommodating bearing port 2; an insert 4 movably installed in the accommodating bearing port 2, A filling space 5 is formed between the bearing port 2 and the insert 4 ; a filling connecting piece for sealing the filling space 5 .

[0033] The filling connector includes: a first filling member 6, a second filling member 7 disposed opposite to the first filling member 6;

[0034] The support base plate 1 is made of metal material, the inclined opening 3 is arranged at a 45° angle, and the top of the insert 4 is provided with an inclined opening 9 matching the inclined opening 3 . The oblique opening 3 reserves the space required for the insert 4 to be deformed by heat, so as to prevent the insert 4 from pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com