Edge grinding device for hot pot blank

A pot blank and edge technology, which is applied in the field of the edge grinding device of the hot pot pot blank, can solve the problem that the polishing machine cannot polish the edge of the pot blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

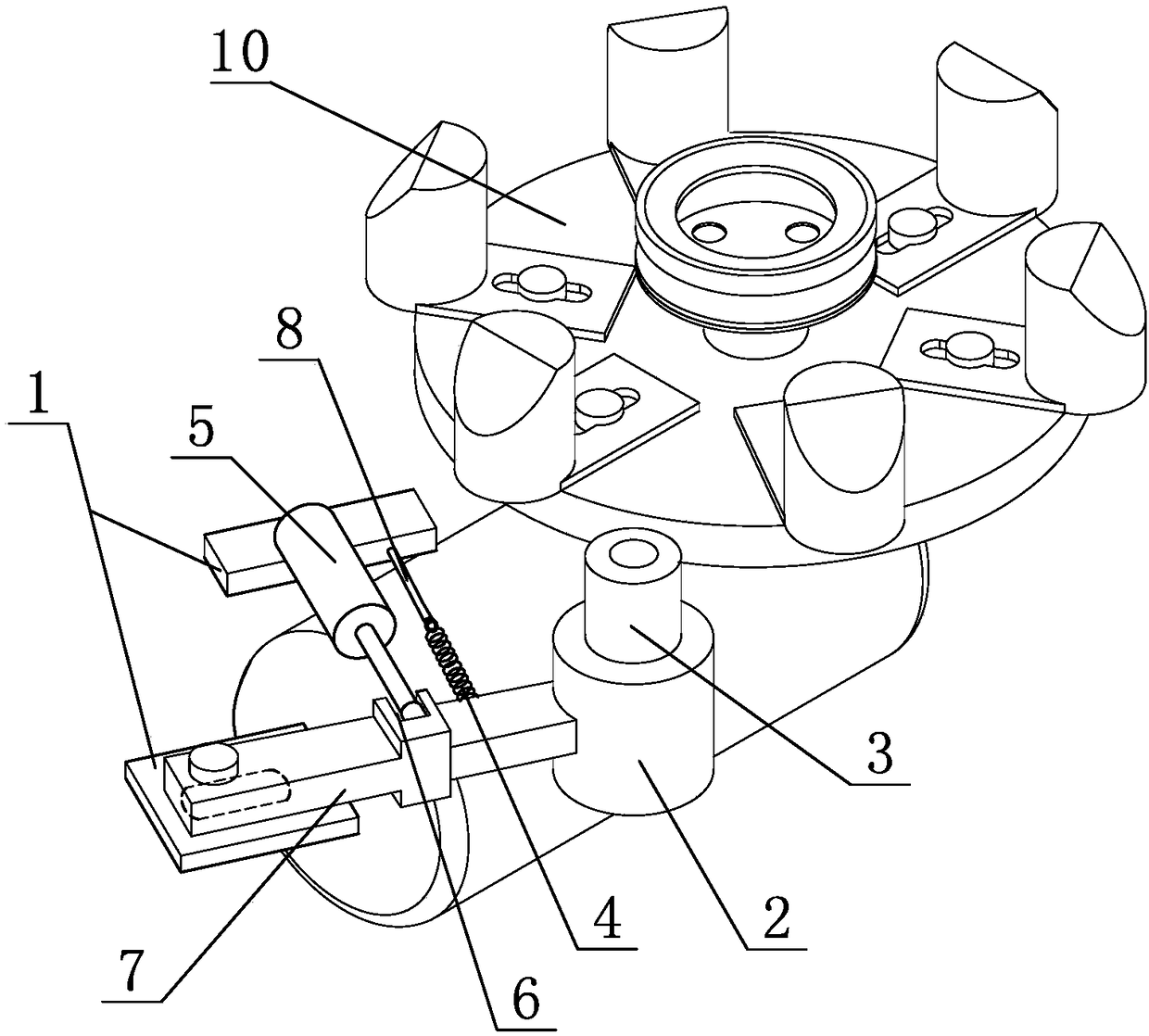

[0015] Such as figure 1 As shown, a hot pot pot blank edge polishing device includes a frame 1, a polishing motor 2 mounted with a polishing wheel 3; the polishing motor 2 is hinged on the frame 1 through a bracket 7; the frame 1 is also provided with The air cylinder 5 that can abut the bracket 7; the air cylinder 5 is used to push the bracket 7 to keep the grinding wheel 3 away from the pot blank positioning fixture 10; there is a tension spring 4 between the frame 1 and the bracket 7; the tension spring 4 is used for Pull the bracket 7 to make the grinding wheel 3 abut against the edge of the pot blank.

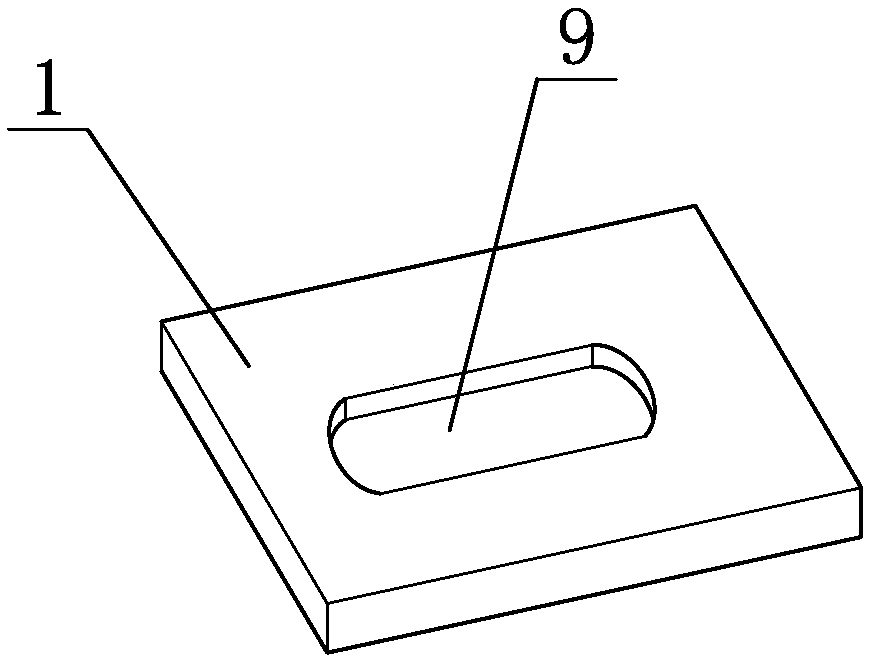

[0016] Such as figure 2 As shown, the rack 1 is provided with a sliding groove 9, and the bracket 7 is hinged in the sliding groove 9. A groove 6 is provided where the cylinder 5 abuts the bracket 7; the rod of the cylinder 5 extends into the groove 6. An eye bolt 8 is provided between the frame 1 and the tension spring 4. One end of the eye bolt 8 is fixed on the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com