Composite microbial bacterium adsorbent and preparation method thereof and sewage treatment method

A technology of composite microbial bacteria and adsorbents, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of low survival rate and content of beneficial bacteria, poor biological activity and adaptability , filter bricks or filter materials are easy to block, etc., to achieve the effect of high quality, long effective time and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

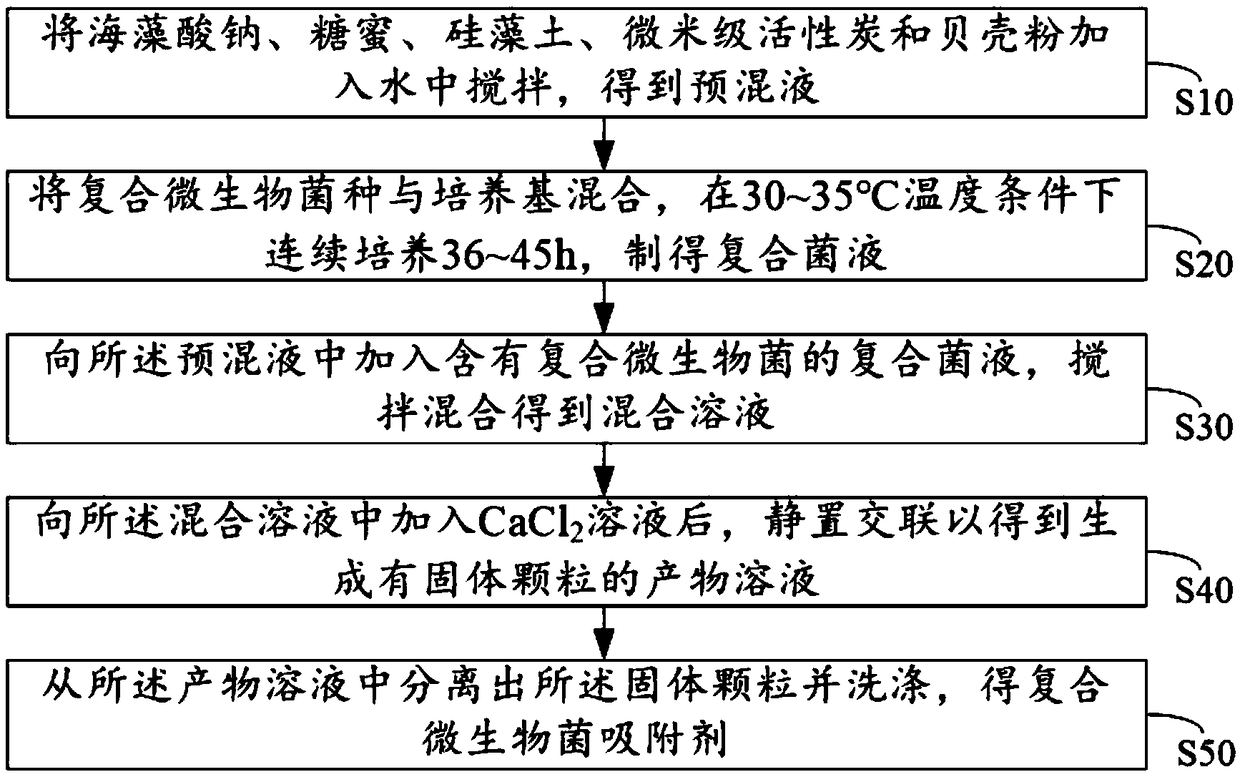

[0038] Further, the present invention also proposes a method for preparing the composite microorganism adsorbent as described above, wherein the composite microorganism is solidified and loaded onto the composite carrier through a cross-linking reaction, figure 1 Shown is an embodiment of the preparation method of the composite microbial bacterial adsorbent provided by the present invention. see figure 1 , In this embodiment, the preparation method of the composite microbial adsorbent includes the following steps:

[0039] Step S10, adding sodium alginate, molasses, diatomaceous earth, micron activated carbon and shell powder into water and stirring to obtain a premix;

[0040] In this embodiment, when step S10 is implemented, in order to make the sodium alginate, molasses, diatomaceous earth, micron-sized activated carbon and shell powder can be uniformly mixed when mixed with water, and to avoid agglomeration, it is preferable to Under the action of stirring, add the sodiu...

Embodiment 1

[0056](1) Preparation of composite bacterial liquid: According to the inoculum amount of 1:100, the composite microbial strain was mixed with the culture medium, and continuously cultured at 30°C for 40 hours to prepare the composite bacterial liquid for use; among them, the composite microbial strain Species include 5 parts of Vickers nitrifying bacteria Y3-2, 6 parts of Nitrosomonas european AT7, 5 parts of denitrifying bacteria (the total amount of denitrifying bacteria Br9, Br15 and Br21), Rhodopseudomonas palustris 12 parts, 6 parts of Saccharomyces ruckeri, 6 parts of sulfur bacteria, 10 parts of Bacillus subtilis, 10 parts of Bacillus licheniformis, 10 parts of Bacillus megaterium, 8 parts of Lactobacillus plantarum, 12 parts of composite photosynthetic bacteria, 7 parts of Saccharomyces cerevisiae ; Each 100g of the culture medium includes the following components: yeast extract 1.2g, peptone 2.8g, syrup 0.25g, beef extract 0.8g, sodium dihydrogen phosphate 0.10g, disod...

Embodiment 2

[0059] (1) Preparation of composite bacteria solution: the steps are the same as in Example 1.

[0060] (2) Preparation of composite microbial bacterium adsorbent: take 1.5g of sodium alginate, 1.5g of diatomaceous earth, 4g of molasses, 1g of micron activated carbon, 2g of shell powder and 90g of water, stir evenly and cool to room temperature to obtain a premix; Then in the obtained premixed solution, add 10 g of the composite bacteria solution prepared by step (1), mix to obtain a mixed solution; under stirring, add 4.5 g of CaCl dropwise to the obtained mixed solution 2 After the solution was added dropwise, it was allowed to stand at a temperature of 20°C for 12 hours, and then the solid particles generated by the crosslinking reaction were separated and washed to obtain a composite microbial bacterium adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com