Strong-flavor flue-cured tobacco variety third Xiang tobacco delay slow baking method

A flue-cured tobacco variety and Luzhou-flavored technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as uneven yellowing, slow water loss, unfavorable appearance and internal quality of Xiangyan No. 3, and improve quality and efficiency Significant, rapid degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] In July 2014, at the experimental site in Shangcun, Lanxi Yao Village, Jiangyong County, Yongzhou City, Hunan Province, the specific implementation of roasting Xiangyan No. 3 of the present invention and traditional roasting techniques for K326 and Yunyan 87:

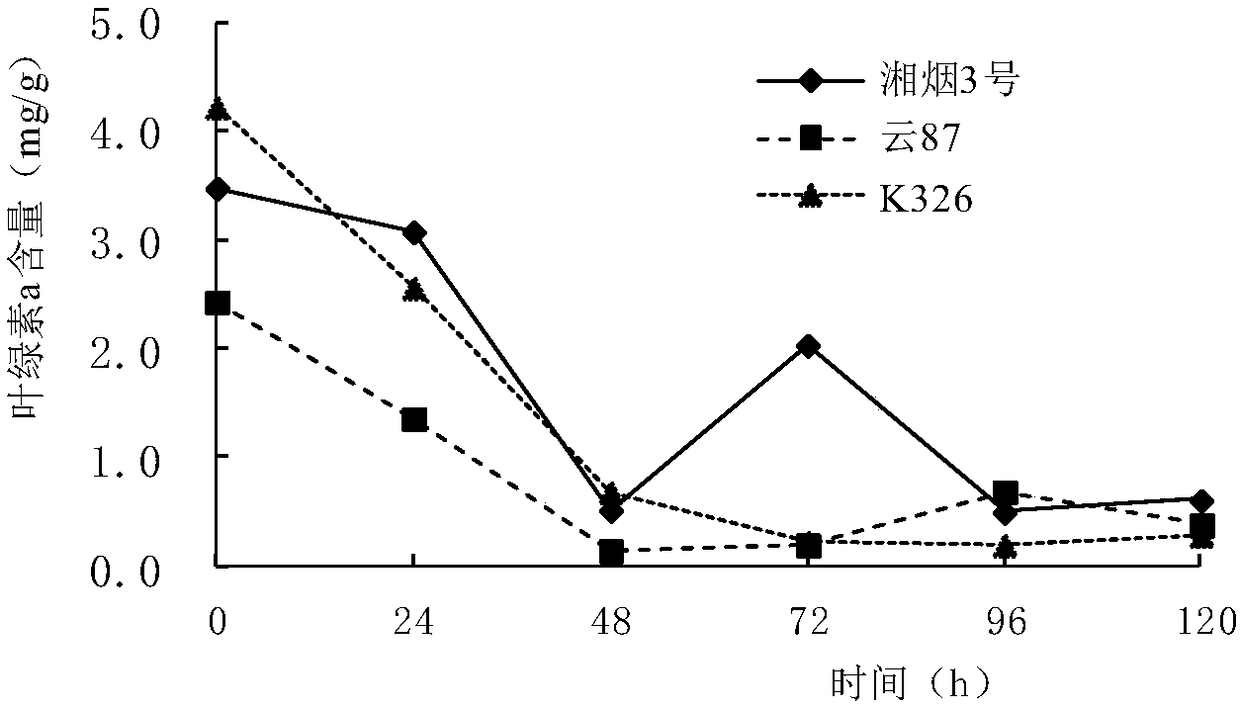

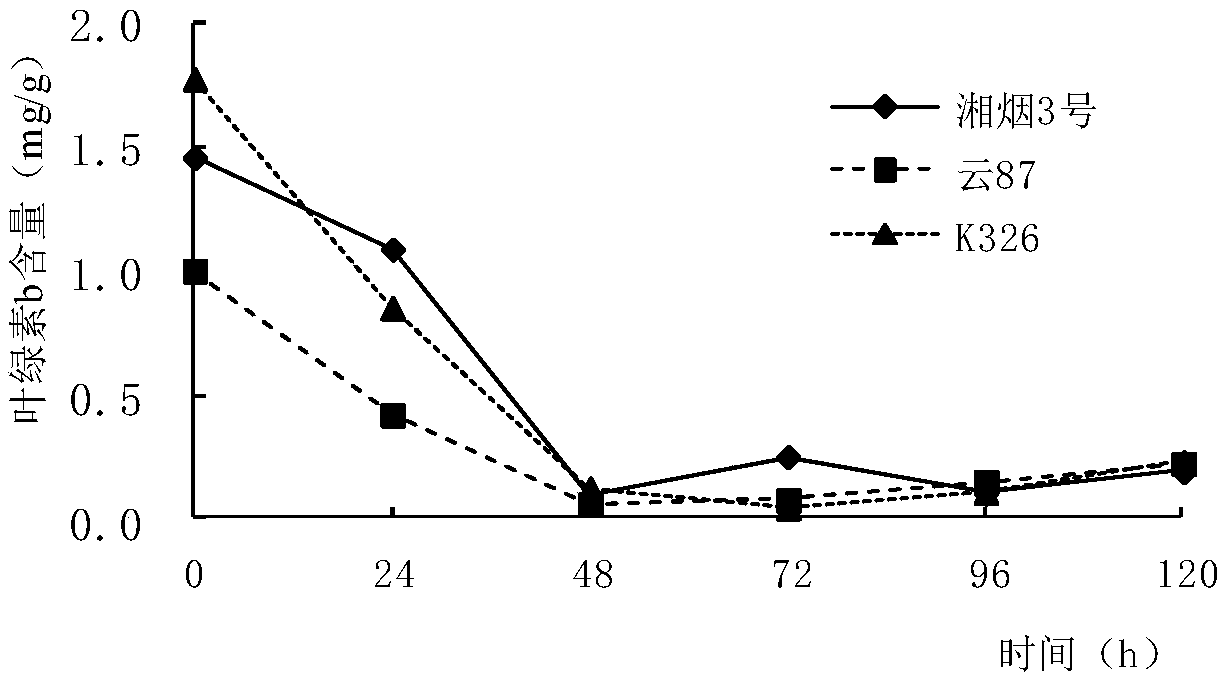

[0030] 1.1 Changes of chlorophyll concentration of different varieties of middle leaves

[0031] Depend on figure 1 It is known that when the three varieties enter the baking room, the chlorophyll a content is K326 > Xiangyan No. 3 > Yunyan 87. When the three varieties are baked for 0-48 hours, the chlorophyll a declines rapidly, slows down in 48-72 hours, and slows down in 72 hours. Afterwards, the content changes very little, and by the end of the roasting, the chlorophyll a content is extremely low. Depend on figure 2It is known that when the chlorophyll b content of the three varieties enters the curing room, K326 reaches 1.777mg / g, Xiangyan No. 3 is 1.459mg / g, and Yunyan 87 is 1.003mg / g. When the three va...

example 2

[0039] In September 2014, in the test site of Gangbang Village, Daoer Township, Huayuan County, Western Hunan, the effect of roasting Xiangyan No. 3 with the time-delayed slow roasting process of the present invention and roasting K326 with the traditional roasting process:

[0040] 2.1 Analysis of economic traits of tobacco leaves in each treatment

[0041] By grading and measuring the cured tobacco leaves, the quality comparison of the tobacco leaves in the whole room (see Table 1): the proportion of the top-quality tobacco after the delay and slow-curing process of the lower tobacco is 5.86%, which is 0.55% higher than the 5.31% of the conventional curing, and the upper-medium tobacco The ratio is 80.93%, which is 6.28% higher than the 74.65% of conventional roasting, and the average price is 17.27 yuan / kg, which is 1.55 yuan / kg higher than the 15.72 yuan / kg of conventional roasting; The proportion of smoke is 38.06%, which is 1.41% higher than that of conventional roasting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com