Microencapsulated lipid and preparation method thereof

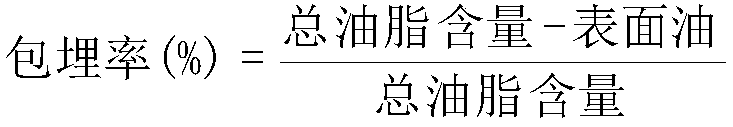

A microencapsulation and microencapsulation technology, which is applied in the fields of gas-containing food ingredients, animal feed molding or processing, animal husbandry, etc., can solve the problems of limited application range of oil, poor oxidation stability of oil, and low embedding rate of oil, etc. , to improve the embedding effect, high embedding rate, and prolong the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Composition of dry matter in the raw material of microcapsule oil, by mass percentage: 60% canola oil, 19.5% whey protein powder, 15.3% corn starch; 1% phospholipid, 4% sodium L-corbate, phosphoric acid Tricalcium 0.2%.

[0039] Preparation of microencapsulated oil:

[0040] 1) Ingredients: Dissolve canola oil, whey protein powder, corn starch, and sodium L-ascorbate in water with a temperature of about 65°C, premix, stir, and mix evenly.

[0041] 2) refinement: using a colloid mill to grind and refine the obtained premix;

[0042] 3) Emulsification: add emulsifier phospholipid, stir and mix;

[0043] 4) Carbon dioxide treatment: Introduce 2000 ppm carbon dioxide into the material obtained in step 3), and refrigerate at 4° C. for 4 hours, and then remove carbon dioxide by physical adsorption;

[0044] 5) Homogenization: homogenize the material obtained in step 4), and the homogenization pressure is 40MPa;

[0045] 6) Spray drying: The material is spray-dried, the inle...

Embodiment 2

[0048] The composition of the dry matter in the raw material of the microcapsule oil is calculated by mass percentage: 50% soybean oil, 20% whey protein powder, 25.9% maltodextrin; 1% monoglyceride succinate, 3% dl-α-tocopherol, Silica 0.1%.

[0049] Preparation of microencapsulated oil:

[0050] 1) Ingredients: Soybean oil, whey protein powder, maltodextrin, and dl-α-tocopherol are dissolved in ingredient water at a temperature of about 60°C, premixed, stirred, and mixed evenly;

[0051] 2) refinement: using a colloid mill to grind and refine the obtained premix;

[0052] 3) Emulsification: add emulsifier monoglyceride succinate, stir and mix;

[0053] 4) Homogenization: homogenize the material obtained in step 3), and the homogenization pressure is 40MPa;

[0054] 5) Carbon dioxide treatment: inject 1000 ppm carbon dioxide into the material obtained in step 4), and refrigerate at 4° C. for 3 hours;

[0055] 6) Spray drying: The material is spray-dried, the inlet air temp...

Embodiment 3

[0058] The composition of the dry matter in the raw material of the microcapsule oil is calculated by mass percentage: 35.6% of corn oil, 34.1% of maltodextrin, 26% of casein powder; 2% of phospholipid, 2% of ascorbyl palmitate, and 0.3% of silicon dioxide.

[0059] Preparation of microencapsulated oil:

[0060] 1) Ingredients: Dissolve corn oil, maltodextrin, casein powder, and ascorbyl palmitate in ingredient water at a temperature of about 65°C, premix, stir, and mix well.

[0061] 2) refinement: using a colloid mill to grind and refine the obtained premix;

[0062] 3) Carbon dioxide treatment: Introduce 1000 ppm carbon dioxide into the material obtained in step 2), and refrigerate at 4°C for 4 hours, and then remove carbon dioxide by physical adsorption;

[0063] 4) Emulsification: add emulsifier phospholipid, stir and mix;

[0064] 5) Homogenization: homogenize the material obtained in step 4), and the homogenization pressure is 45MPa;

[0065] 6) Spray drying: The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com