Brittle-failure-resistant chocolate coating and method for coating frozen beverage with brittle-failure-resistant chocolate coating

A chocolate coating and frozen drink technology, applied in frozen sweets, cocoa, food science, etc., can solve problems affecting sales, affecting brittleness, easy cracking, etc., to ensure the coating effect, not easy to crack, and enhance product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

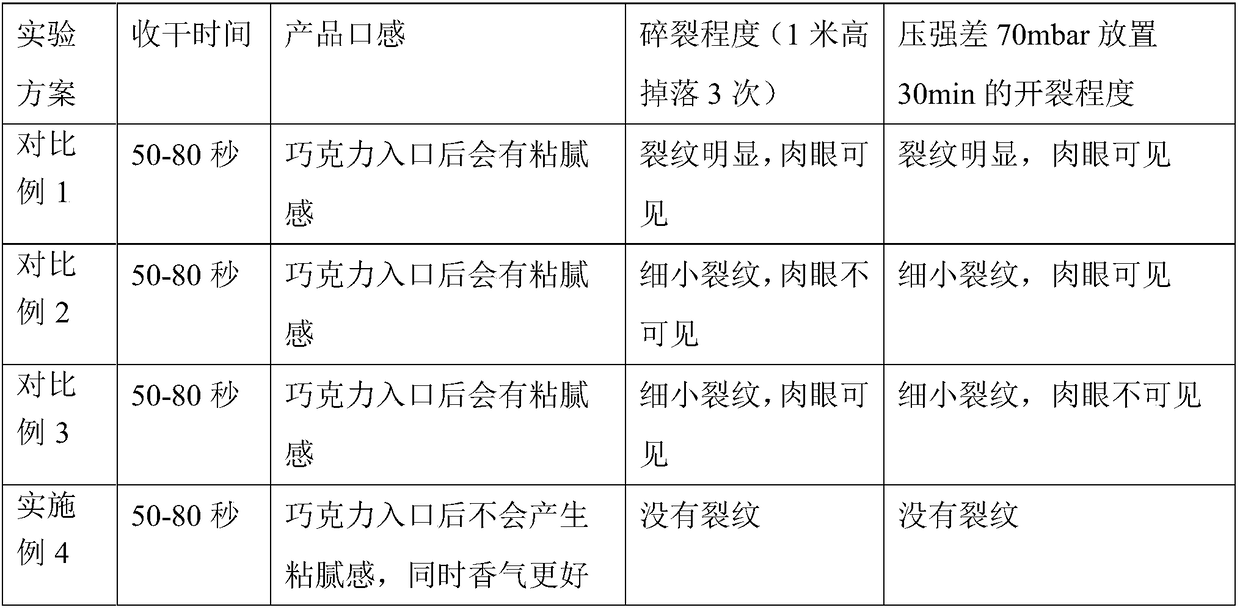

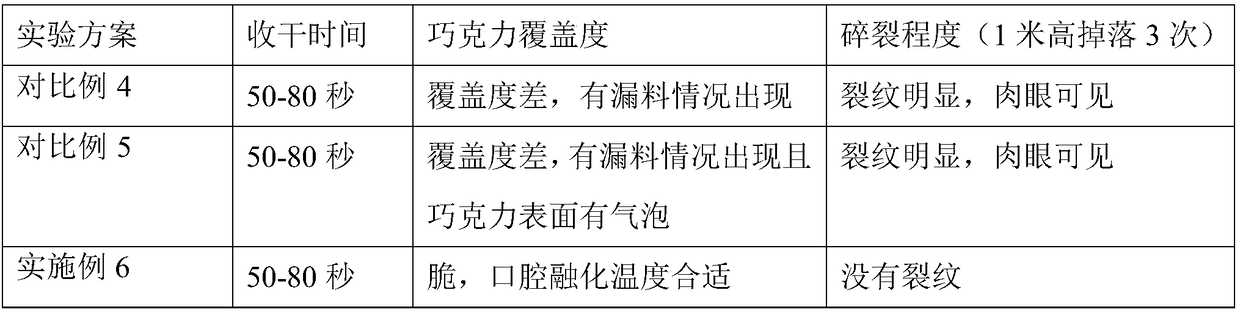

Examples

Embodiment 1

[0030] Embodiment 1 A kind of anti-brittle chocolate coating

[0031] A preparation method for an anti-brittle chocolate coating, comprising the following steps:

[0032] 1) Weigh the following raw materials: 330g white sugar, 170g milk powder, 160g cocoa mass, 60g natural anhydrous butter, 260g cocoa butter, 3g lecithin, 3g PGPR90;

[0033] 2) After mixing the raw materials, sterilize at 70° C. for 15 minutes; grind until the fineness reaches 25 μm; scouring to make the water content 1.0 percent, to obtain.

Embodiment 2

[0034] Embodiment 2 A kind of anti-brittle chocolate coating

[0035] A preparation method for an anti-brittle chocolate coating, comprising the following steps:

[0036] 1) Weigh the following raw materials: 400g white sugar, 130g milk powder, 120g cocoa mass, 40g natural anhydrous butter, 300g cocoa butter, 1g lecithin, 1g PGPR90;

[0037] 2) After mixing the raw materials, sterilize at 75° C. for 20 minutes; grind until the fineness reaches 34 μm; scouring to make the water content 1.4%, and the product is obtained.

Embodiment 3

[0038] Embodiment 3 A kind of anti-brittle chocolate coating

[0039] A preparation method for an anti-brittle chocolate coating, comprising the following steps:

[0040] 1) Weigh the following raw materials: 370g white sugar, 155g milk powder, 140g cocoa mass, 50g natural anhydrous butter, 280g cocoa butter, 2g lecithin, 2g PGPR90;

[0041] 2) After mixing the raw materials, sterilize at 72° C. for 18 minutes; grind until the fineness reaches 30 μm; scouring to make the water content 1.2%, and the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com