Electric pile end plate with gas pressure buffering and dehumidifying functions

A technology of gas pressure and gas-electric stacks, applied in circuits, fuel cells, electrical components, etc., can solve the problems of low power density, small volume specific power density, and poor integration, so as to reduce quantity and production costs and increase volume power Density, the effect of accelerating the pace of marketization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

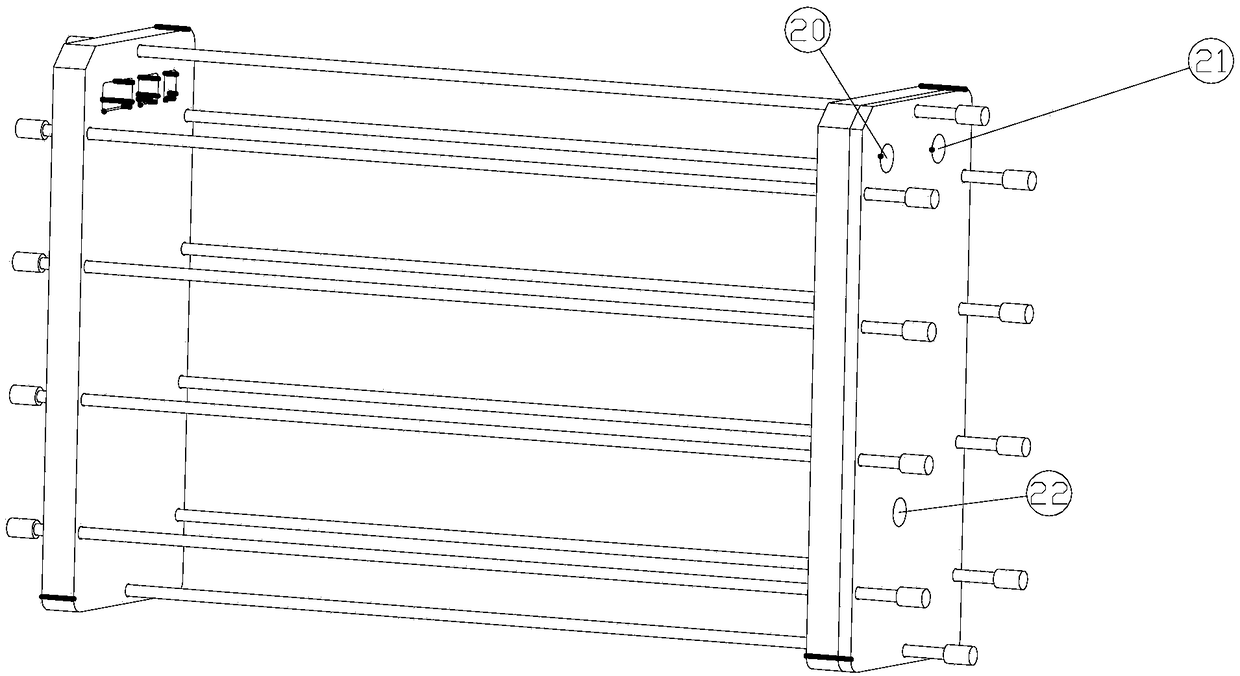

[0024] Embodiment: A cell stack end plate with gas pressure buffering and humidification functions, comprising a first end plate located at the stack gas inlet side and a second end plate located at the cell stack gas outlet side. Both the first end plate and the second end plate are hollow structures.

[0025] The inner cavity of the first end plate is divided into two parts: a fuel gas side intake buffer zone 9 and an oxidant gas side intake buffer zone 10 . The inner cavity of the second end plate is divided into two parts, the tail gas buffer zone 14 on the fuel gas side and the tail gas buffer zone 13 on the oxidant gas side, by the separator. Each buffer zone is provided with a fuel gas side intake buffer adjustment ridge 11 , an oxidant gas side intake buffer adjustment ridge 12 , a fuel gas side exhaust gas buffer adjustment ridge 18 and an oxidant gas side exhaust gas buffer adjustment ridge 19 . Each regulating ridge is shaped in accordance with hydrodynamics, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com