A batch calibration method for electrochemical formaldehyde sensor detection

A technology of formaldehyde sensor and calibration method, which is applied in the field of formaldehyde detection, can solve problems such as numerical instability, inability to observe the trend of sensor changes, batch error calibration, and affect the accuracy of detection results, so as to improve work efficiency, ensure accuracy, and avoid data difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

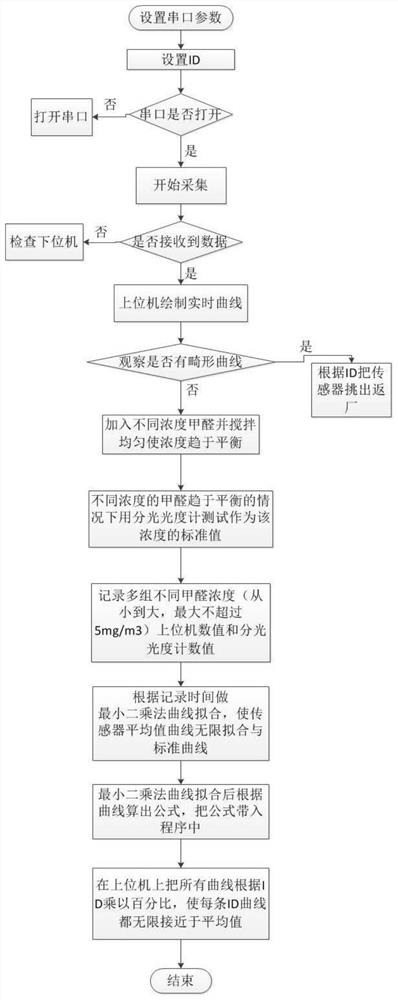

[0027] Example: see figure 1 , figure 1 The flow chart of the batch calibration method for electrochemical formaldehyde sensor detection provided by the embodiment of the present invention. According to different needs, figure 1 The execution order of the steps in the shown flowchart can be changed, some steps can be split into several steps, and some steps can be omitted.

[0028] Step 1: Open the upper computer software, set the serial port parameters of the upper computer, judge whether the serial port is open, if the serial port is open, connect the port number, and choose to connect to the lower computer; if the serial port is not open, reset the serial port parameters, and then connect to the lower computer;

[0029] Step 2: The upper computer sets the ID of the sensor of the lower computer, and writes the ID into the lower computer, where the ID is set to increase from 1 in turn, and each additional ID will be written into the lower computer, such as 1 , 2, 3······, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com