Distributed sewage pre-treatment system

A sewage pretreatment and distributed technology, applied in the direction of waterway system, sewer system, water supply device, etc., can solve the problem that can not reflect the advantages of pipe gallery, can not completely eliminate the city's "pull link, non-pressurized sewage pipes are not conducive to being included in the comprehensive management system" Corridor and other problems, to achieve the effect of reducing investment costs, conducive to water absorption performance, and uniform water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

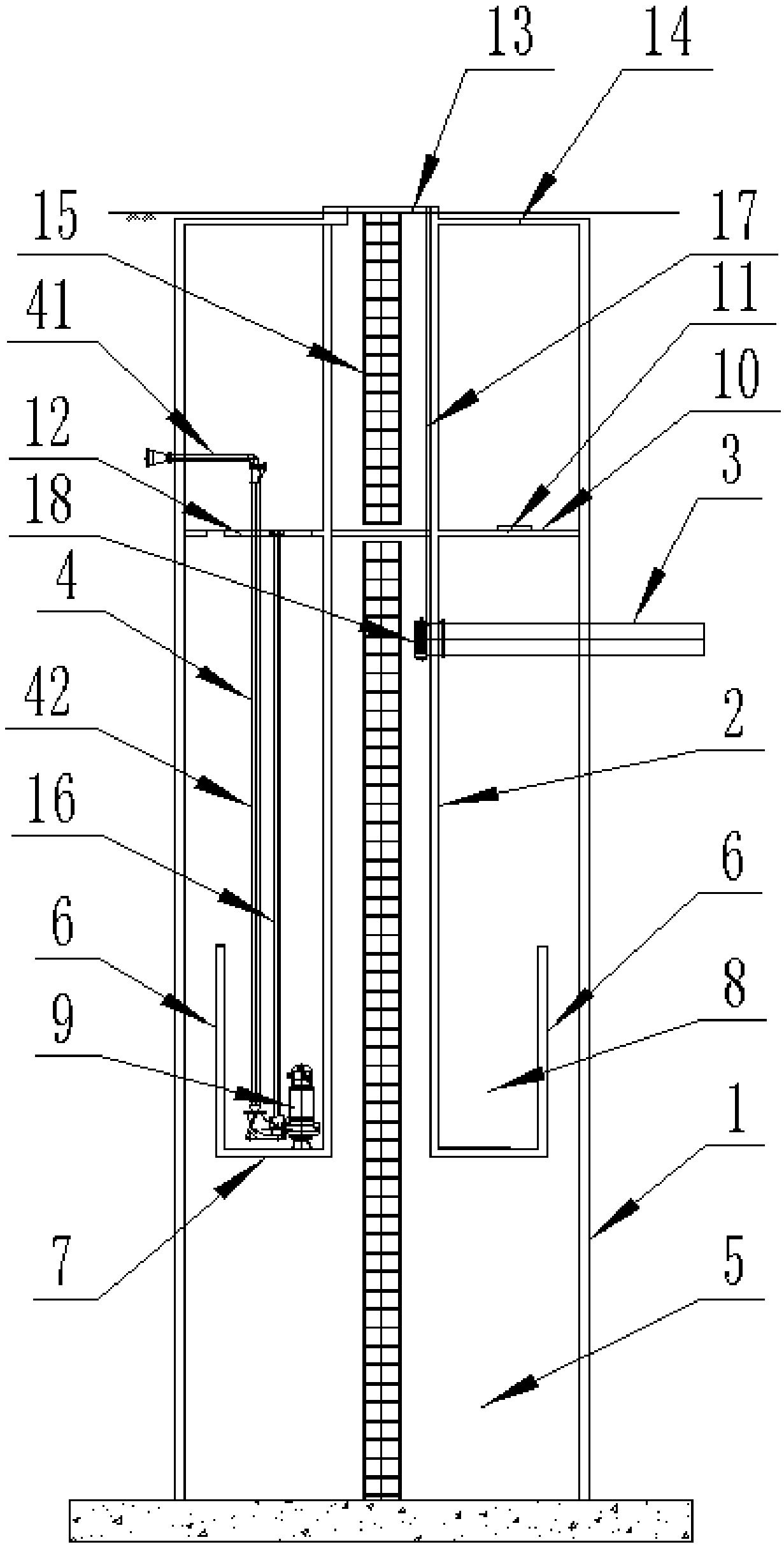

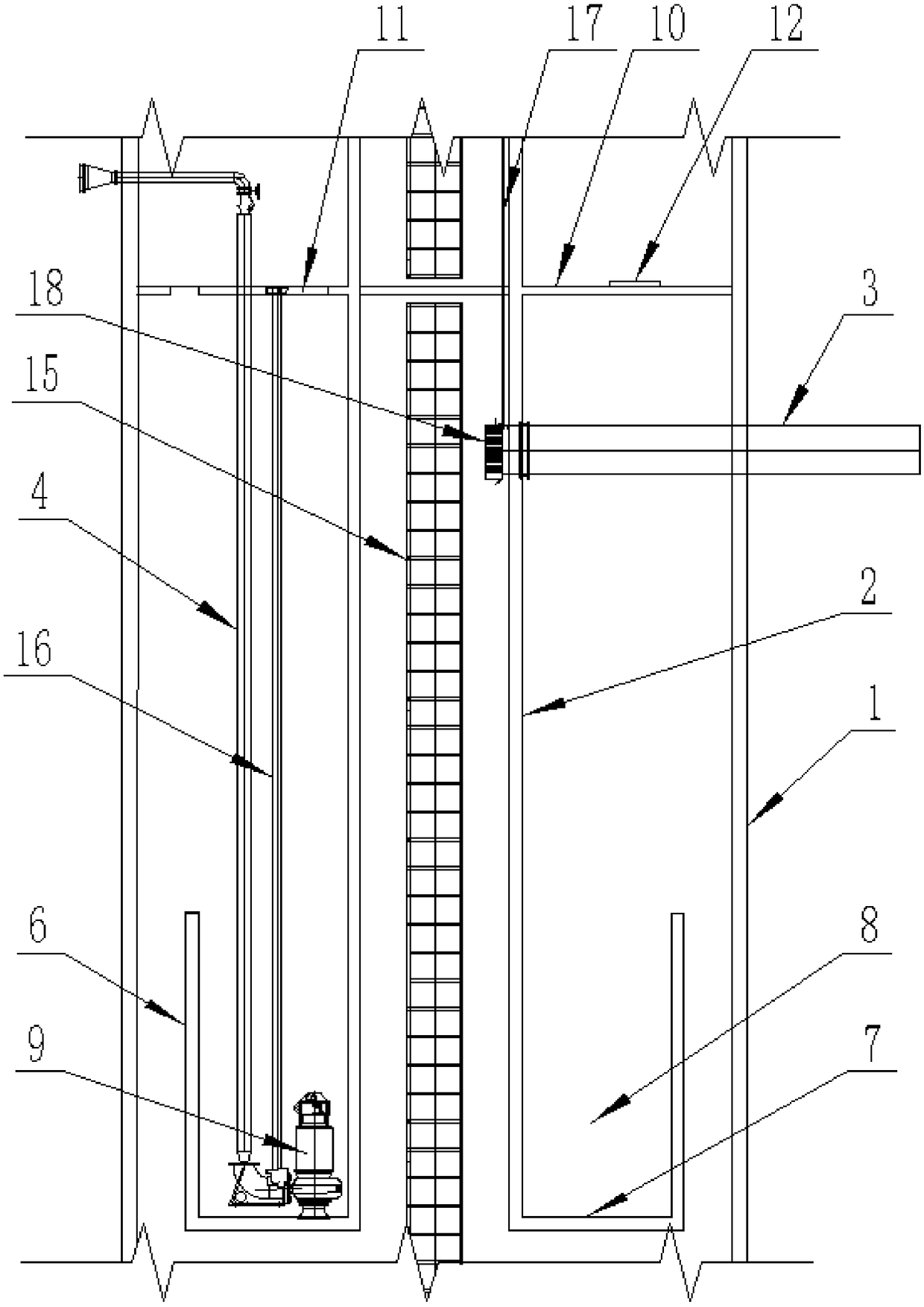

[0032] A distributed sewage pretreatment system, comprising an outer wellbore 1, a central wellbore 2, a water inlet pipe 3 and an outlet pipe 4, the central wellbore 2 is set inside the outer wellbore 1, and the lower end of the central wellbore 2 is higher than the lower end of the outer wellbore 1 A sewage storage area 5 is formed between the lower end of the central wellbore 2 and the bottom of the outer wellbore 1, and a cylindrical overflow dam 6 is arranged between the central wellbore 2 and the outer wellbore 1, and the lower end of the overflow dam 6 connects the bottom plate 7 with the The central well shaft 2 is connected, and a water absorption well 8 is formed between the overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com