Drum type washing and drying integral machine

An all-in-one, drum-type technology, applied in the field of washing machines, can solve the problems of low condensation efficiency, easy blockage of condensation pipes, and occupation of internal space, etc., so as to save drying time, reduce secondary pollution, and reduce space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

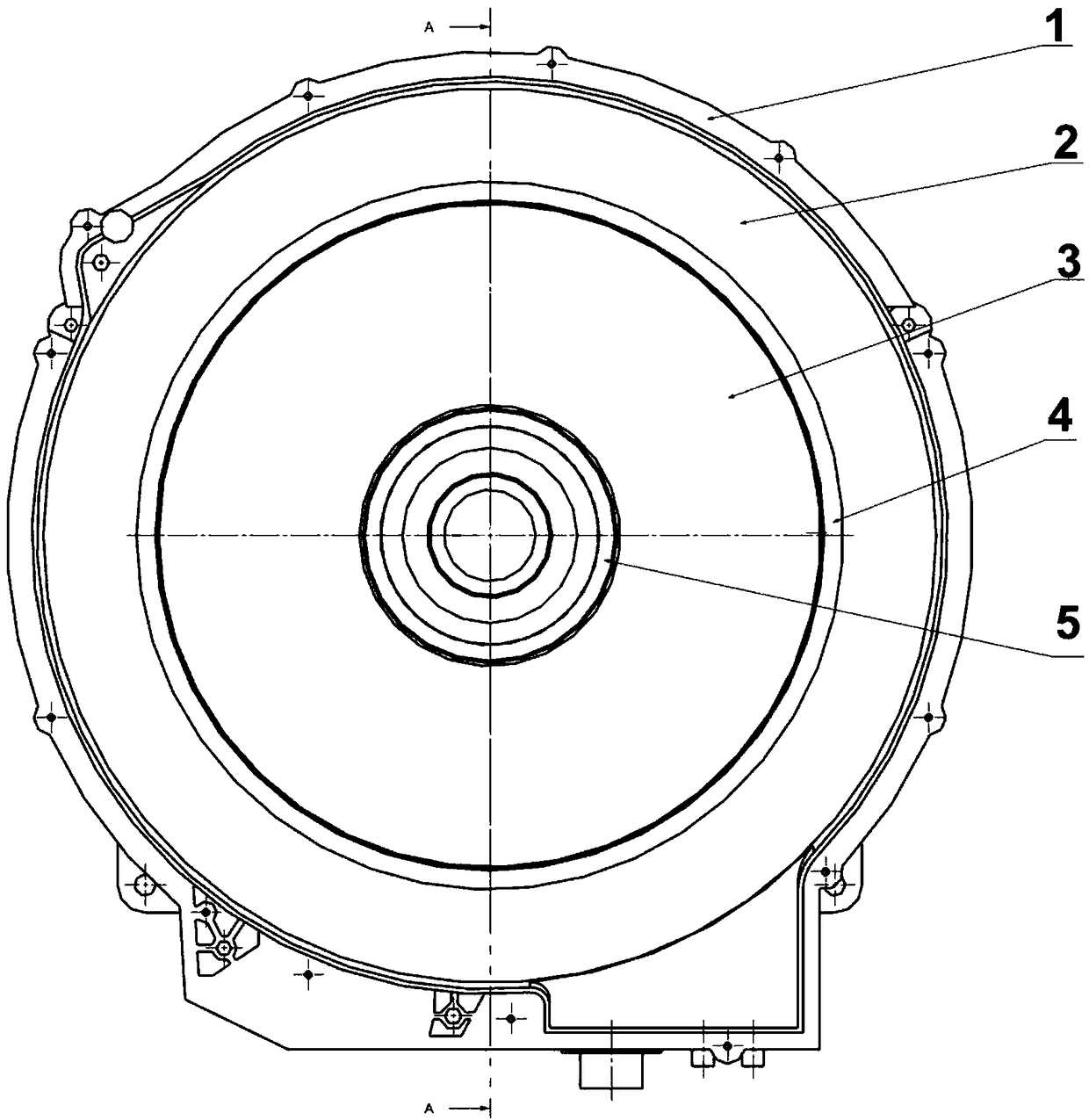

[0035] The invention is a drum type washing and drying machine, such as figure 1 As shown, it includes a water tank 1; the water tank 1 includes a rear side wall 2 of the water tank; the rear side wall 2 of the water tank is provided with a shaft hole;

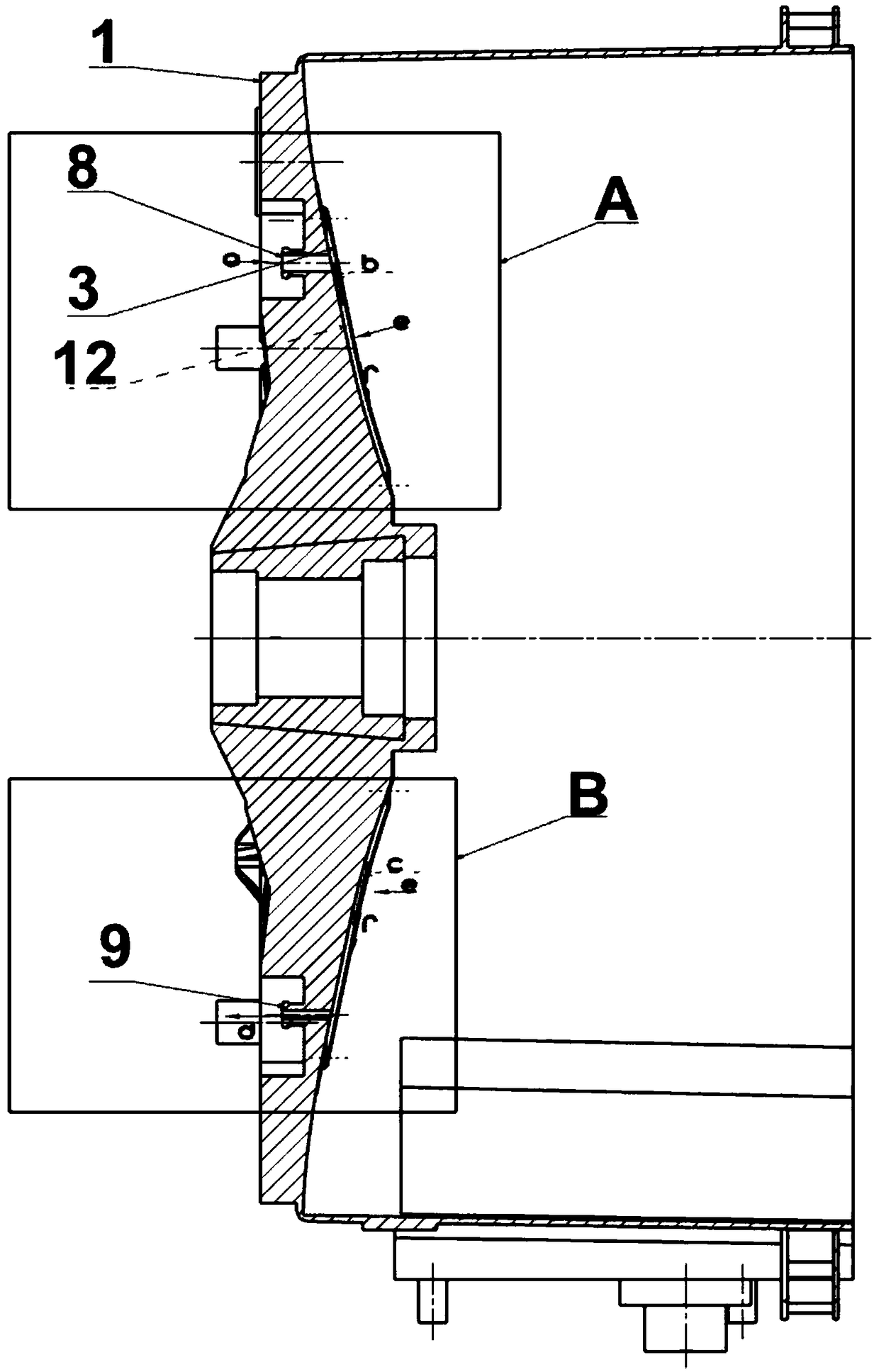

[0036] like image 3 As shown, the inner surface of the rear side wall 2 of the water tank is provided with several threaded mounting holes, the inner surface of the rear side wall 2 of the water tank is fixedly connected with the condensation plate 3, and a closed chamber is formed between the rear side wall 2 of the water tank and the condensation plate 3 12. The airtight chamber 12 is used to store the cooling water when the cooling water circulates;

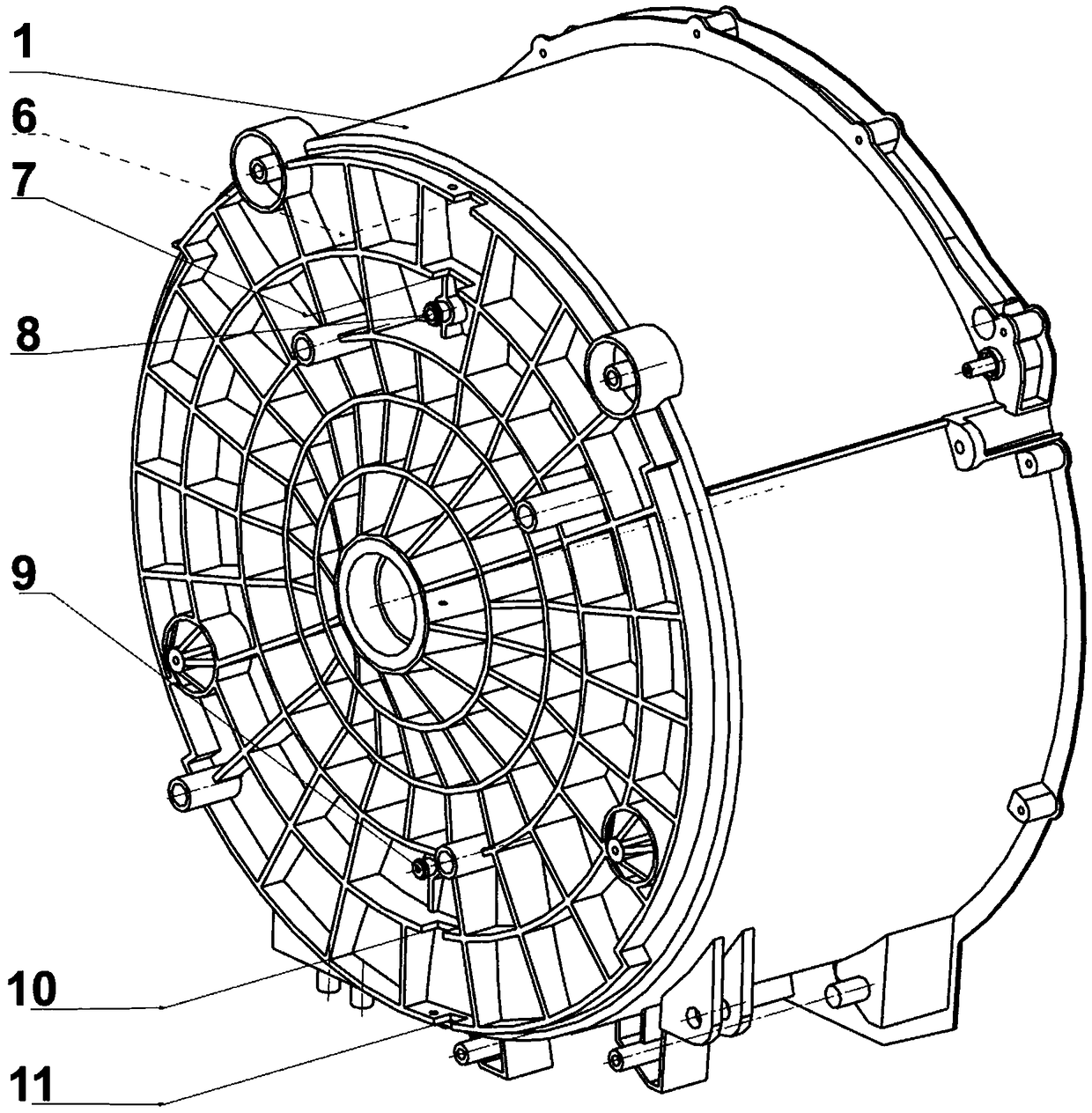

[0037] like Figure 2-5 As shown, the outer surface of the rear side wall 2 of the bucket is fixedly connected with a cooling water inlet 8 and a cooling water outlet 9 communicating with the airtight chamber 12;

[0038] Wherein, the outer surface of the rear side wall 2 ...

Embodiment 2

[0048] The invention is a drum type washing and drying machine, such as figure 1 As shown, it includes a water tank 1; the water tank 1 includes a rear side wall 2 of the water tank; the rear side wall 2 of the water tank is provided with an inner tube shaft hole; the inner tube shaft hole is used for the transmission shaft between the motor and the inner tube to pass through;

[0049] The inner surface of the rear side wall 2 of the water bucket is provided with several cylindrical bosses, and there are threaded holes on the cylindrical bosses; the inner surface of the rear side wall 2 of the water bucket is provided with two through holes;

[0050] like Figure 7-9 As shown, the condensing pan 3 is a closed chamber structure; one side of the condensing pan 3 is fixedly connected with a water inlet 31 and a water outlet 32 communicating with the airtight chamber; the water inlet 31 and the water outlet 32 respectively pass through the rear side wall 2 The through hole on...

Embodiment 3

[0052] The condensing pan 3 is a metal plate structure, such as an aluminum alloy plate or a stainless steel plate, which is fixedly connected to the surface of the rear side wall 2 of the water tank by screws, and is completely attached to the surface of the rear side wall 2 of the water tank, and no airtight chamber 12 is provided; The cooling water passes through the cooling water supply assembly and directly flows through the surface of the condensation pan 3 through the cooling water inlet 8. Strip ribs can be set on the condensation pan 3 to realize the diversion of the cooling water, so that the cooling water can flow through the entire condensation pan more fully. The surface of the plate 3 increases the condensation area of the cooling water. After the cooling water flows through the surface of the condensing plate 3, it directly flows into the bottom of the bucket 1 and is discharged by the drain pump;

[0053] As a preferred solution, the condensation pan 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com