An Evaporation Process for Non-discoloration of Glass

A glass and evaporation technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating and other directions, can solve the problems of yellowish and reddish glass surface, affecting product quality, and yellowish glass surface. To achieve the effect of removing dirt, preventing batch scrap, and solving different colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An evaporation process for glass without discoloration, comprising the following steps:

[0028] Step 1: Ion source cleaning, specifically: under the conditions of argon flow rate of 800-1200Sccm and oxygen flow rate of 400-800Sccm, plasma cleaning is performed on the glass in the coating equipment with a voltage of 750-850V, and the cleaning time is 480- 720S.

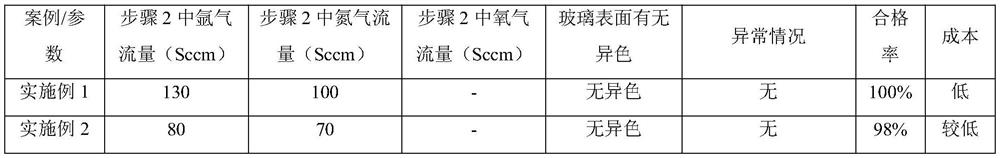

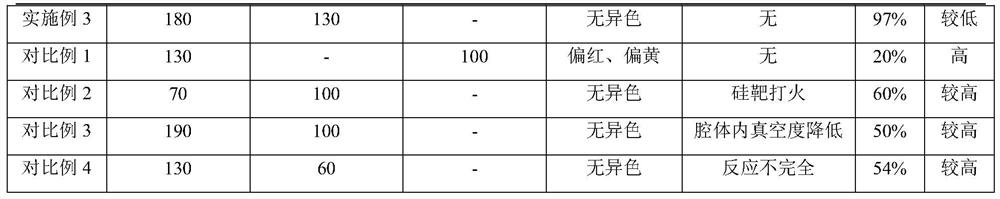

[0029] Step 2: Deposit Si x N y , specifically: vacuumize the cavity of the coating equipment to 3×10 -5 -5×10 -5 Torr, and argon and nitrogen are introduced, and the silicon molecules in the silicon target are sputtered out by radio frequency sputtering silicon targets, and the silicon molecules and nitrogen react in the cavity to form Si x N y , and deposited on the glass surface, wherein the argon flow rate is 80-180Sccm, the nitrogen flow rate is 70-130Sccm, the RF sputtering silicon target power is 4.5-5.5KW, where x is a natural number from 1 to 3, and y is from 2 to 6 Natural number (preferably, Si...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is that in step 2, the flow rate of argon gas is 80Sccm, the flow rate of nitrogen gas is 70Sccm, the power of the RF sputtering silicon target is 4.5KW, and the rest are the same as in embodiment 1.

[0041] The processing effect of this embodiment is shown in Table 1.

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 is that in step 2, the flow rate of argon gas is 180Sccm, the flow rate of nitrogen gas is 130Sccm, the power of the RF sputtering silicon target is 5.5KW, and the rest are the same as in embodiment 1.

[0044] The processing effect of this embodiment is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com