Anti-twist jointless coupling

A coupling and anti-twist technology, applied in the field of metal materials, can solve the problems of unsatisfactory strength and corrosion resistance, failure to improve alloy performance, high yield strength, etc., and achieve the effects of increased compactness, good thermal conductivity, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

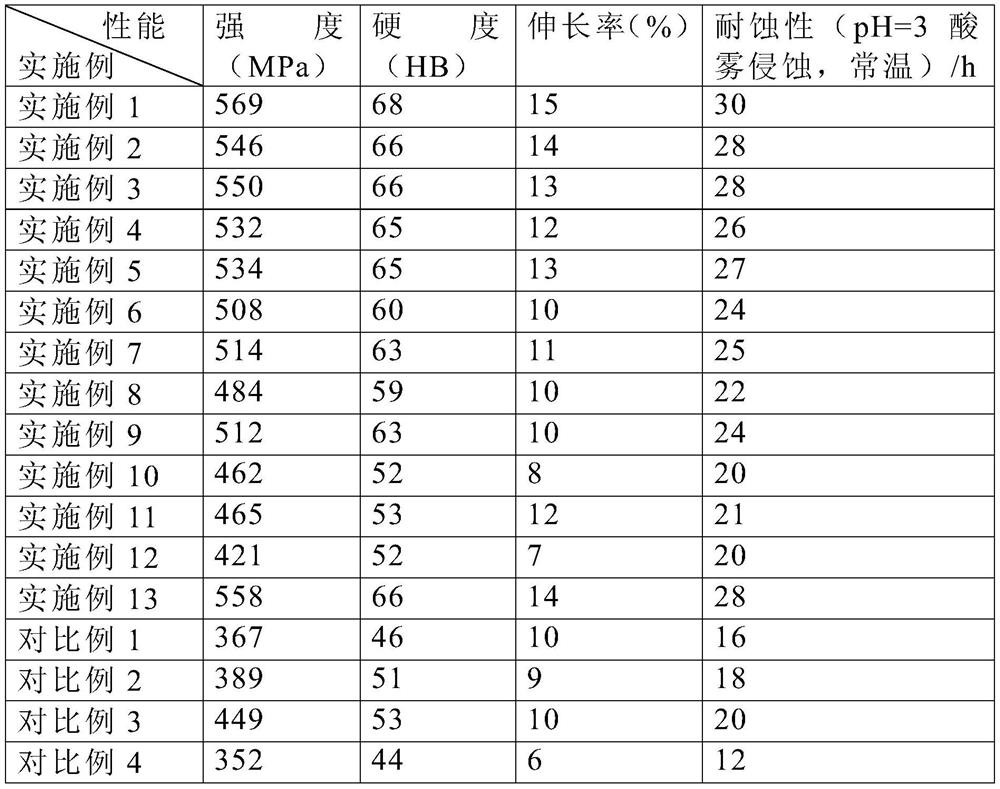

Examples

Embodiment 1

[0033] Ingredients: Weigh raw materials according to the above aluminum alloy ratio, including silver-impregnated bamboo charcoal: 0.3%, Si: 0.1%, Zr: 0.15%, Ni: 0.07%, Co: 0.15%, and the balance is Al and impurities, of which immersion silver Bamboo charcoal is composed of ultra-fine bamboo charcoal with a content of 85% of the silver-impregnated bamboo charcoal, nano-silver particles with a content of 8% of the silver-impregnated bamboo charcoal, and kaolin powder with a content of 7% of the silver-impregnated bamboo charcoal, and the nano-silver particles are on the superfine bamboo charcoal The distribution is 50 nanometer silver / mm 2 bamboo charcoal;

[0034] Pre-treatment: Preheat ultra-fine bamboo charcoal in vacuum until sticky and slippery carbon graphite appears on the surface of bamboo charcoal, then evenly spread kaolin powder on the surface of bamboo charcoal, continue heating and add 4 atmospheres to form composite bamboo charcoal, and then deposit nano-silver on...

Embodiment 2

[0039] Ingredients: Weigh raw materials according to the above aluminum alloy ratio, including silver-impregnated bamboo charcoal: 0.1%, Si: 0.05%, Zr: 0.1%, Ni: 0.04%, Co: 0.1%, and the balance is Al and impurities, of which immersion silver Bamboo charcoal is composed of ultra-fine bamboo charcoal with a content of 80% of the silver-impregnated bamboo charcoal, nano-silver particles with a content of 10% of the silver-impregnated bamboo charcoal, and kaolin powder with a content of 10% of the silver-impregnated bamboo charcoal, and the nano-silver particles are on the superfine bamboo charcoal The distribution is 10 nanometer silver / mm 2 bamboo charcoal;

[0040] Pre-treatment: Preheat ultra-fine bamboo charcoal in vacuum until sticky and slippery carbon graphite appears on the surface of bamboo charcoal, then evenly spread kaolin powder on the surface of bamboo charcoal, continue heating and add 4 atmospheres to form composite bamboo charcoal, and then deposit nano-silver o...

Embodiment 3

[0045] Ingredients: Weigh raw materials according to the above aluminum alloy ratio, including silver-impregnated bamboo charcoal: 0.5%, Si: 0.15%, Zr: 0.2%, Ni: 0.1%, Co: 0.2%, and the balance is Al and impurities, of which Bamboo charcoal is composed of superfine bamboo charcoal with a content of 90% of the silver-impregnated bamboo charcoal, nano-silver particles with a content of 5% of the silver-impregnated bamboo charcoal, and kaolin powder with a content of 5% of the silver-impregnated bamboo charcoal, and the nano-silver particles are on the superfine bamboo charcoal The distribution is 100 nano silver / mm 2 bamboo charcoal;

[0046] Pre-treatment: Preheat ultra-fine bamboo charcoal in vacuum until sticky and slippery carbon graphite appears on the surface of bamboo charcoal, then evenly spread kaolin powder on the surface of bamboo charcoal, continue heating and add 4 atmospheres to form composite bamboo charcoal, and then deposit nano-silver on the composite Bamboo c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com