Method for producing marsh gas through two-stage united anaerobic fermentation of anaerobic digestion fiber and waste oil

A technology of anaerobic digestion and anaerobic fermentation, applied in biochemical equipment and methods, methods based on microorganisms, fermentation, etc., can solve the problems of cumbersome biodiesel production process, collapse of anaerobic digestion system, and difficult application, and achieve The effect of improving utilization rate and gas production, increasing adhesion and contact area, good lipase activity and acid production characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

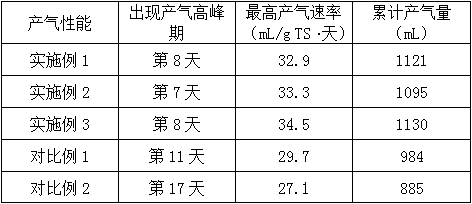

Embodiment 1

[0032] This embodiment provides a method for producing biogas by anaerobic digestion of fiber and waste oil through two-stage joint anaerobic fermentation. The method includes the following steps:

[0033] (1) Anaerobic digestion fiber pretreatment: anaerobic digestion fiber was pretreated with 4% acetic acid at 121°C for 2 hours, and the liquid-solid ratio was 10mL / g; after acetic acid pretreatment, 10% ammonia water was used at 121°C Under pretreatment for 1 hour, the pretreated anaerobic digested fiber is washed and then dried;

[0034] (2) Preparation of anaerobic fermentation strains: adding anaerobic digested sludge and fat-degrading bacteria to the basal medium as anaerobic fermentation strains; the mass ratio of anaerobic digested sludge, fat-degrading bacteria and basal medium 120:1:1000;

[0035] (3) Adding inorganic medium: mixing the pretreated anaerobic digested fiber and anaerobic fermentation bacteria in step (1) and then adding an inorganic medium to obtain a ...

Embodiment 2

[0048] This embodiment provides a method for producing biogas by anaerobic digestion of fiber and waste oil through two-stage joint anaerobic fermentation. The method includes the following steps:

[0049] (1) Anaerobic digestion fiber pretreatment: anaerobic digestion fiber was pretreated with 4% acetic acid at 121°C for 2 hours, and the liquid-solid ratio was 10mL / g; after acetic acid pretreatment, 10% ammonia water was used at 121°C Under pretreatment for 1 hour, the pretreated anaerobic digested fiber is washed and then dried;

[0050] (2) Preparation of anaerobic fermentation strains: adding anaerobic digested sludge and fat-degrading bacteria to the basal medium as anaerobic fermentation strains; the mass ratio of anaerobic digested sludge, fat-degrading bacteria and basal medium 160:1:1000;

[0051] (3) Adding inorganic medium: mixing the pretreated anaerobic digested fiber and anaerobic fermentation bacteria in step (1) and then adding an inorganic medium to obtain a ...

Embodiment 3

[0064] This embodiment provides a method for producing biogas by anaerobic digestion of fiber and waste oil through two-stage joint anaerobic fermentation. The method includes the following steps:

[0065] (1) Anaerobic digestion fiber pretreatment: anaerobic digestion fiber was pretreated with 4% acetic acid at 121°C for 2 hours, and the liquid-solid ratio was 10mL / g; after acetic acid pretreatment, 10% ammonia water was used at 121°C Under pretreatment for 1 hour, the pretreated anaerobic digested fiber is washed and then dried;

[0066] (2) Preparation of anaerobic fermentation strains: adding anaerobic digested sludge and fat-degrading bacteria to the basal medium as anaerobic fermentation strains; the mass ratio of anaerobic digested sludge, fat-degrading bacteria and basal medium is 210:1:1000;

[0067] (3) Adding inorganic medium: mixing the pretreated anaerobic digested fiber and anaerobic fermentation bacteria in step (1) and then adding an inorganic medium to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com