Thermoplastic polyurethane and preparation method thereof

A thermoplastic polyurethane and isocyanate technology, applied in the field of polyurethane synthesis, can solve time-consuming problems, achieve cost reduction, excellent material performance, and promote development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

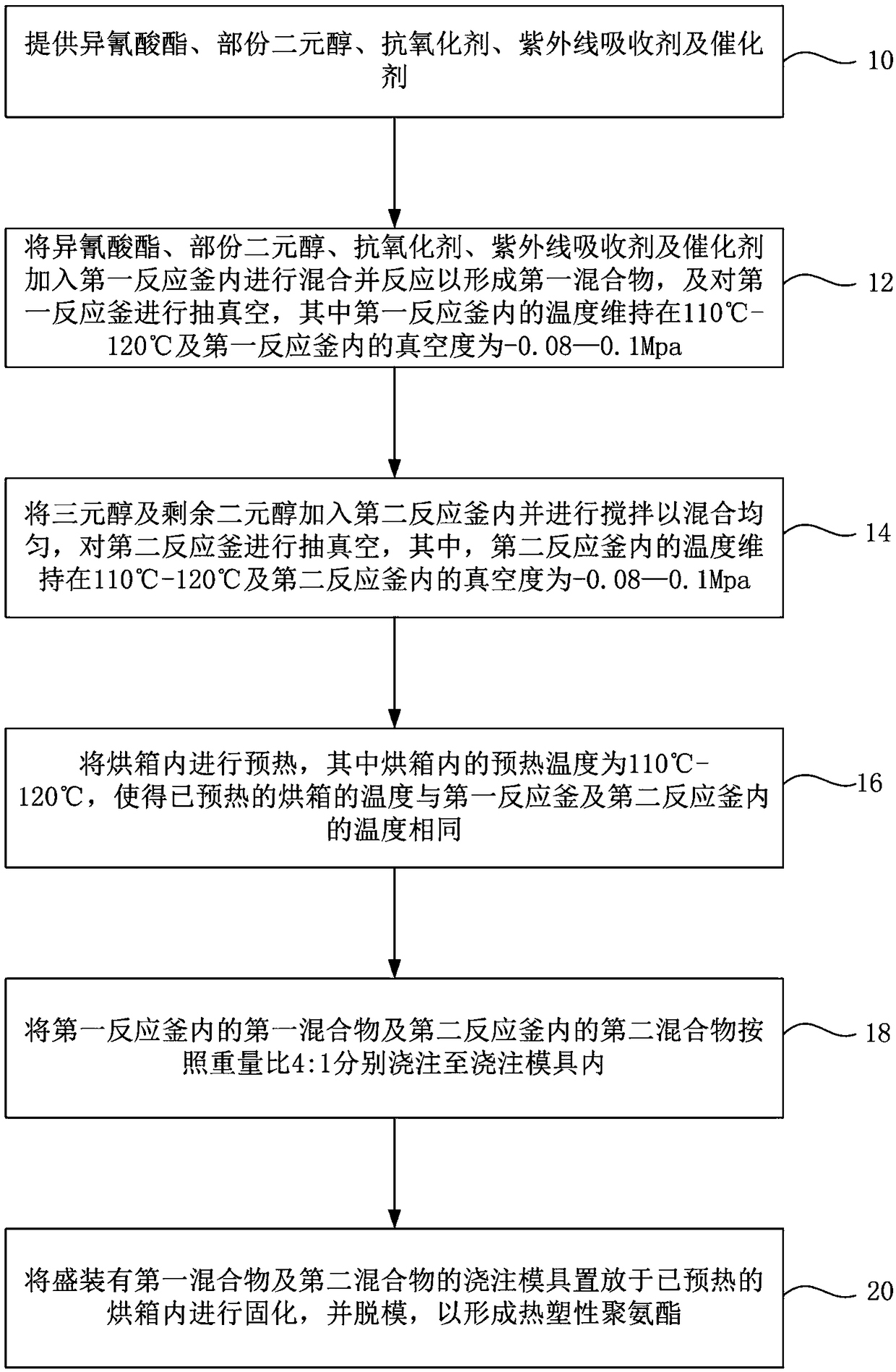

[0023] First, 60-65 parts by weight of isocyanate, 5-7.5 parts by weight of dihydric alcohol, 0.5 parts by weight of antioxidant, 1 part by weight of ultraviolet absorber and 1 part by weight of A catalyst with a number of 0.0005 is added into the first reactor for reaction to form a first mixture, and the temperature in the first reactor is maintained between 110°C and 120°C, preferably 120°C. And vacuumize the inside of the first reaction kettle, so that the vacuum degree in the first reaction kettle is -0.08-0.1Mpa. In this step, because the mixing reaction will release a lot of heat, the temperature in the first reaction tank will exceed 120°C, so after the reaction is completed and the first mixture is formed, the temperature in the first reaction tank will be lowered to 120°C Continue to use the next steps.

[0024] Then, add the remaining 5-7.5 parts by weight of dibasic alcohols and 20-25 parts by weight of tribasic alcohols into the second reactor, heat and stir to m...

Embodiment 2

[0027] In Example 2, different from Example 1, the weight fraction of dihydric alcohol added to the first reactor is changed from 5-7.5 to 10-12.5 and the weight of trihydric alcohol added to the second reactor The number of parts is changed from 20-25 to 10-15, and accordingly, the optimal conditions for preparing thermoplastic polyurethane are found.

[0028] First, 60-65 parts by weight of isocyanate, 10-12.5 parts by weight of dihydric alcohol, 0.5 parts by weight of antioxidant, 1 part by weight of ultraviolet absorber, and 1 part by weight of A catalyst with a number of 0.0005 is added into the first reactor for mixing and reacting to form a first mixture, and the temperature in the first reactor is maintained between 110°C and 120°C, preferably 120°C. And vacuumize the inside of the first reactor, so that the vacuum degree in the first reactor is -0.08-0.1 Mpa. In this step, because the mixing reaction will release a lot of heat, the temperature in the first reaction tan...

Embodiment 3

[0036] In Example 3, the difference from Example 1 and Example 2 is that the weight fraction of dihydric alcohol added to the first reactor is changed to 7.5-10 and the weight of trihydric alcohol added to the second reactor The number of parts is 15-20. Similarly, the purpose of adjusting the parts by weight of dihydric alcohol and trihydric alcohol is also to find out the best conditions for preparing thermoplastic polyurethane.

[0037] First, 60-65 parts by weight of isocyanate, 7.5-10 parts by weight of dihydric alcohol, 0.5 parts by weight of antioxidant, 1 part by weight of ultraviolet absorber, 1 part by weight of A catalyst with a number of 0.0005 is added into the first reactor for mixing and reacting to form a first mixture, and the temperature in the first reactor is maintained between 110°C and 120°C, preferably 120°C. And carry out vacuumizing in the first reactor, make the vacuum degree in the first reactor be-0.08-0.1Mpa, same in this mixing step, because the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com