Novel chlorine dioxide generator

A chlorine dioxide and generator technology, applied in chlorine dioxide, chlorine oxide and other directions, can solve the problems of slow discharge of waste liquid from pipelines, unfavorable production efficiency of chlorine dioxide generator reproduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

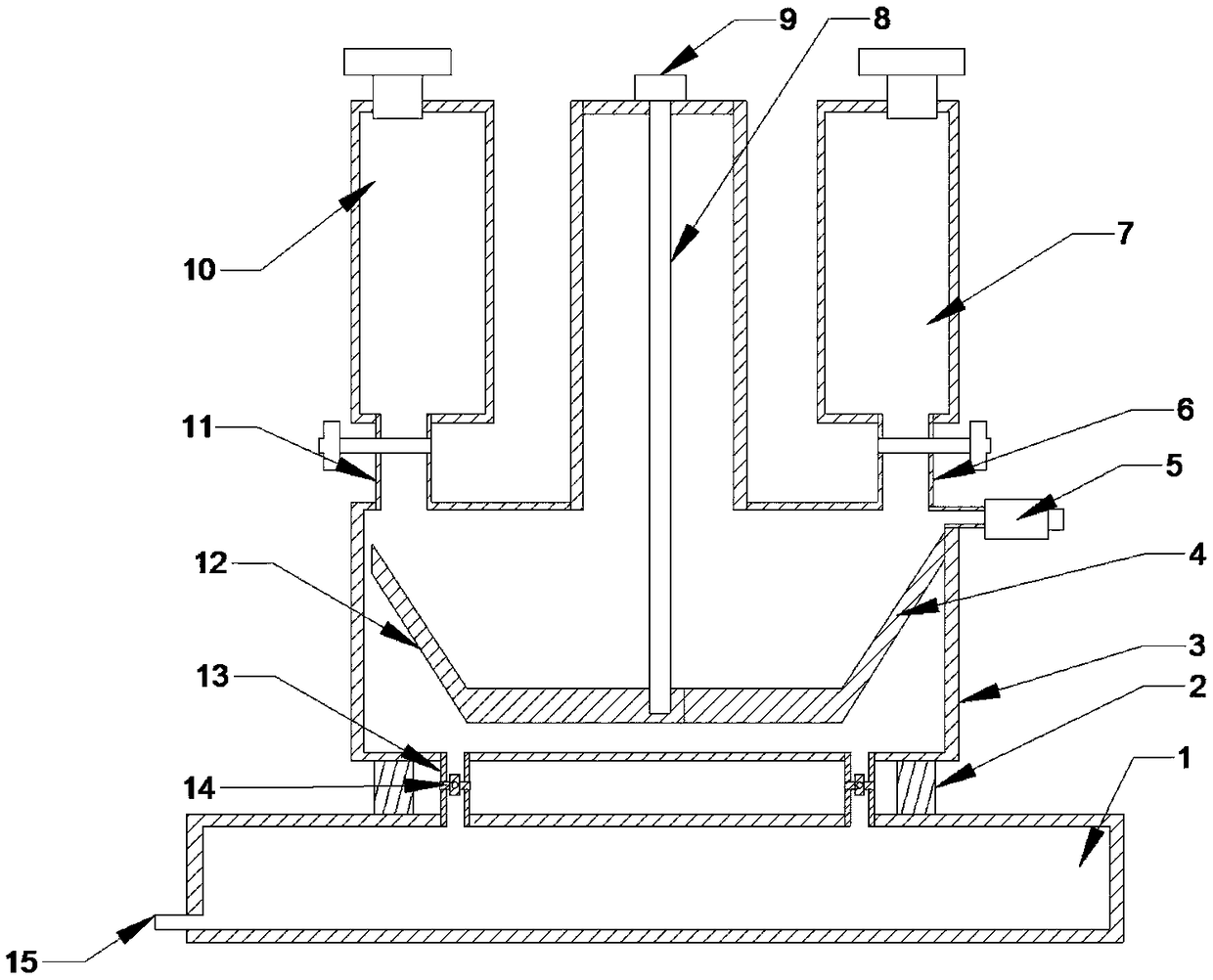

[0026] see figure 1 , a novel chlorine dioxide generator, comprising a reaction tank 3, the side wall of the upper part of the reaction tank 3 tank is provided with a jet device 5 communicating with its inner cavity; the lower part of the inner cavity of the reaction tank 3 is provided with an opening and closing container, The open-close container includes a fixed part 4 and a rotating part 12 that can be spliced with each other. The rotating part 12 is connected with a rotating rod 8 extending outside the reaction tank 3. The rotating part 12 can be rotated and fixed with the rotating rod 8 Part 4 is spliced or disconnected, and its splicing state is a container with a cavity on the top, and there is a leak between the rotating part 12 and the fixed part 4 in its disconnected state; the bottom of the reaction tank 3 is provided with a drain pipe 13, and the drain pipe 13 is located below the opening and closing container.

[0027] In the present embodiment, after the ch...

Embodiment 2

[0029] see figure 1 , a novel chlorine dioxide generator, comprising a reaction tank 3, the side wall of the upper part of the reaction tank 3 tank is provided with a jet device 5 communicating with its inner cavity; the lower part of the inner cavity of the reaction tank 3 is provided with an opening and closing container, The open-close container includes a fixed part 4 and a rotating part 12 that can be spliced with each other. The rotating part 12 is connected with a rotating rod 8 extending outside the reaction tank 3. The rotating part 12 can be rotated and fixed with the rotating rod 8 Part 4 is spliced or disconnected, and its splicing state is a container with a cavity on the top, and there is a leak between the rotating part 12 and the fixed part 4 in its disconnected state; the bottom of the reaction tank 3 is provided with a drain pipe 13, and the drain pipe 13 is located below the opening and closing container.

[0030] The rotating rod 8 is provided with a r...

Embodiment 3

[0033] see figure 1 , a novel chlorine dioxide generator, comprising a reaction tank 3, the side wall of the upper part of the reaction tank 3 tank is provided with a jet device 5 communicating with its inner cavity; the lower part of the inner cavity of the reaction tank 3 is provided with an opening and closing container, The open-close container includes a fixed part 4 and a rotating part 12 that can be spliced with each other. The rotating part 12 is connected with a rotating rod 8 extending outside the reaction tank 3. The rotating part 12 can be rotated and fixed with the rotating rod 8 Part 4 is spliced or disconnected, and its splicing state is a container with a cavity on the top, and there is a leak between the rotating part 12 and the fixed part 4 in its disconnected state; the bottom of the reaction tank 3 is provided with a drain pipe 13, and the drain pipe 13 is located below the opening and closing container.

[0034] Reaction tank 3 upper end is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com