3D printing method used for printing elbow pipe in axial direction based on five-axis printing platform

A printing platform, 3D printing technology, applied in the field of space 3D printing to achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and present embodiment is carried out under the premise of technical solution of the present invention, provides detailed implementation and specific operation process, but protection scope of the present invention is not limited to the following the embodiment.

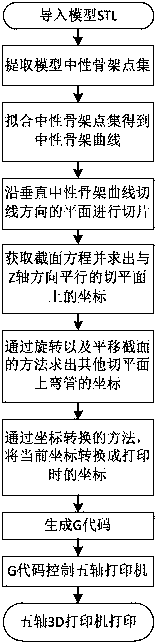

[0036] like figure 1 As shown, a 3D printing method based on a five-axis printing platform to print an elbow along the axial direction includes the following steps:

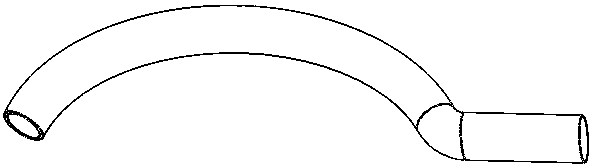

[0037] Step 1: This example uses SolidWorks 2014 software as the 3D modeling software to establish figure 2 The bend pipe fitting model shown is stored as an STL format file;

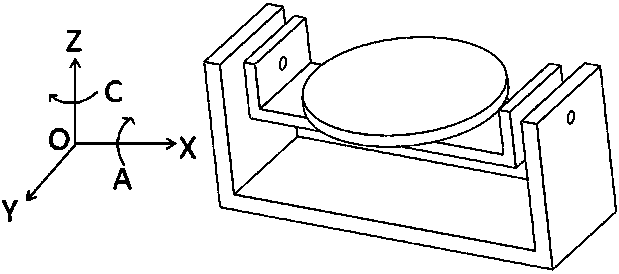

[0038] The second step: if image 3 As shown, the model is placed in the spatial rectangular coordinate system, and according to the characteristics of the five-axis linkage 3D printer, the A axis rotating around the X axis (the swing axis of the printing platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com