Pipe inner wall positioning and cooling device and method

A cooling device and a technology for the inner wall of the pipe, which is applied in the field of cooling the inner wall of the pipe, can solve problems such as the melting of the oxide scale of the steel pipe, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

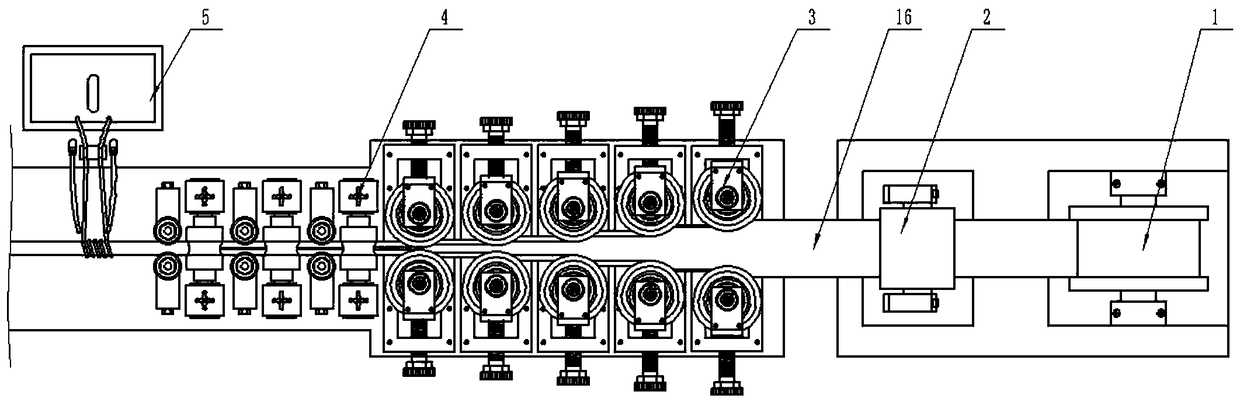

[0058] A tube inner wall positioning cooling device, such as Figure 5 , 6 , 7, 8, and 12, including: liquid supply pipe 10, liquid storage tank 6, infusion pipe 7, water supply pump 8, support 9, self-rotating nozzle 15, temperature sensor 17, thermostat, relay. The lower end of the infusion pipe 7 is connected to the liquid storage tank 6, the water nozzle of the water supply pump 8 is connected to the right end of the infusion pipe 7, and the drain nozzle of the water supply pump 8 is connected to the right end of the liquid supply pipe 10. The water supply pump 8 and the bracket 9 have screws 113. The water supply pump 8 is fixed by rotating the screws 113. The self-rotating nozzle 15 is connected to the left end of the liquid supply pipe 10. The temperature sensor 17 is fixedly connected to the outer surface of the liquid supply pipe 10. The temperature sensor 17 is close to the self-rotating nozzle. 15, located at the right end of the self-rotating nozzle 15, the thermo...

Embodiment 2

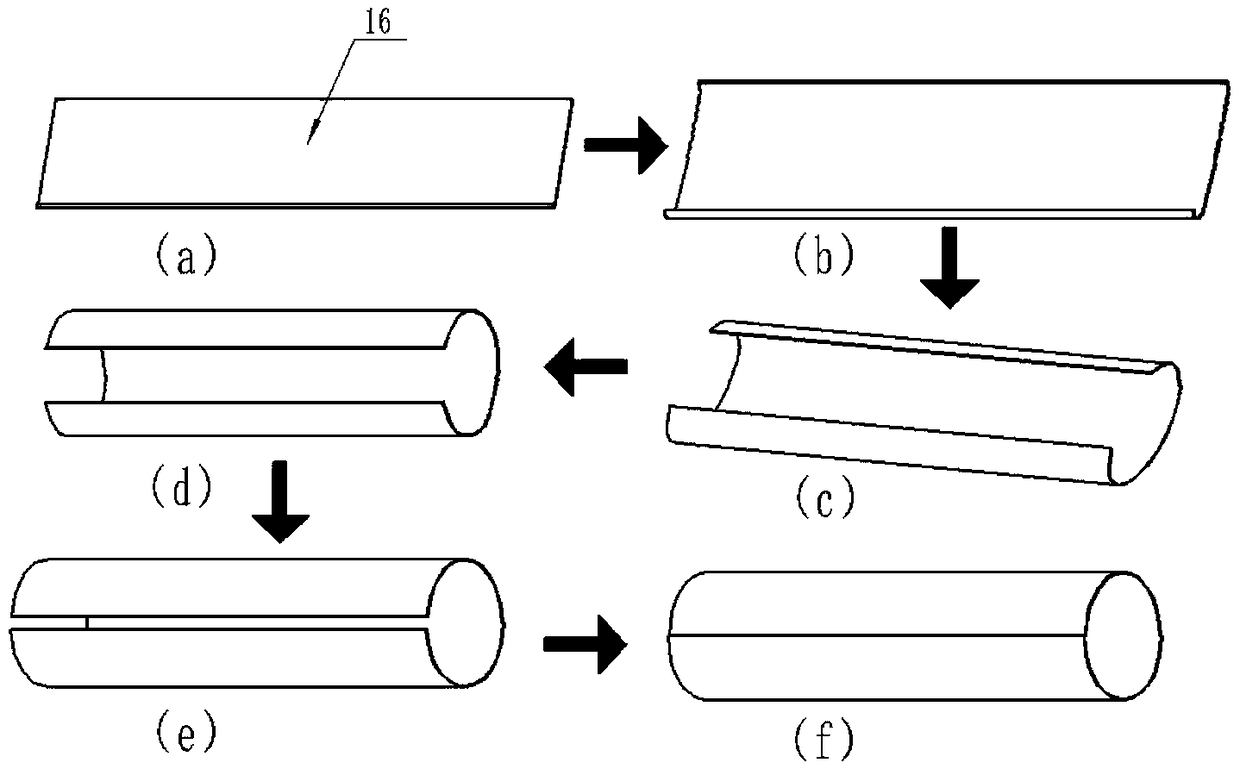

[0079] A method for positioning and cooling the inner wall of a tube, comprising the following steps:

[0080] Adjust the thermostat, the thermostat compares the temperature produced when the existing welding device 5 welds the steel pipe to set the temperature, when the signal detected by the temperature sensor 17 indicates that the existing welding device 5 welded steel pipe reaches the set temperature, the thermostat will Connect the relay to make the water supply pump 8 energized;

[0081] Positioning, by sliding the water supply pump 8, further controlling the movement of the liquid supply pipe 10, when the temperature sensor 17 on the liquid supply pipe 10 detects that the welded steel pipe of the existing welding device 5 reaches the set temperature (checked by the thermostat), then the The screw 113 fixes the water supply pump 8 so that the self-rotating nozzle 15 is inside the steel pipe at the welding position;

[0082] Liquid supply, when the temperature sensor 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com