Paper file mould-proof bacteriostatic agent and preparation method thereof

A technology of anti-mildew, antibacterial, and paper archives, applied in the fields of botanical equipment and methods, fungicides, biocides, etc. Bacterial performance, improving the effect of anti-mildew and bacteriostatic time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

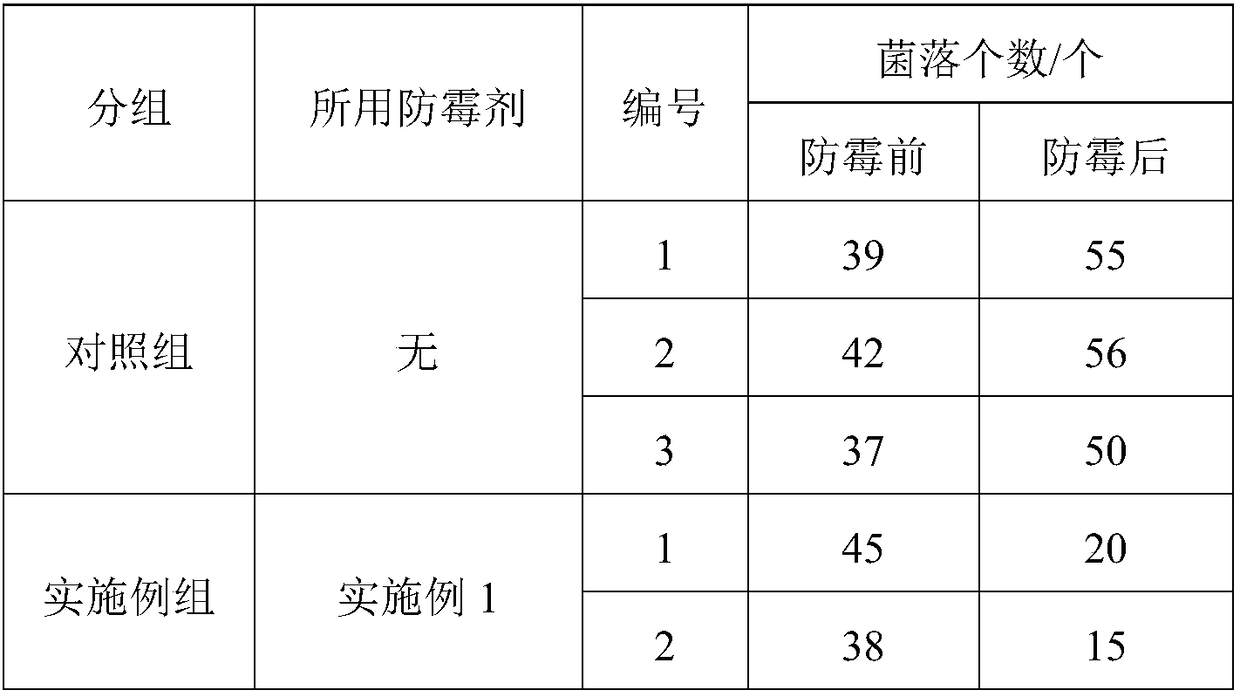

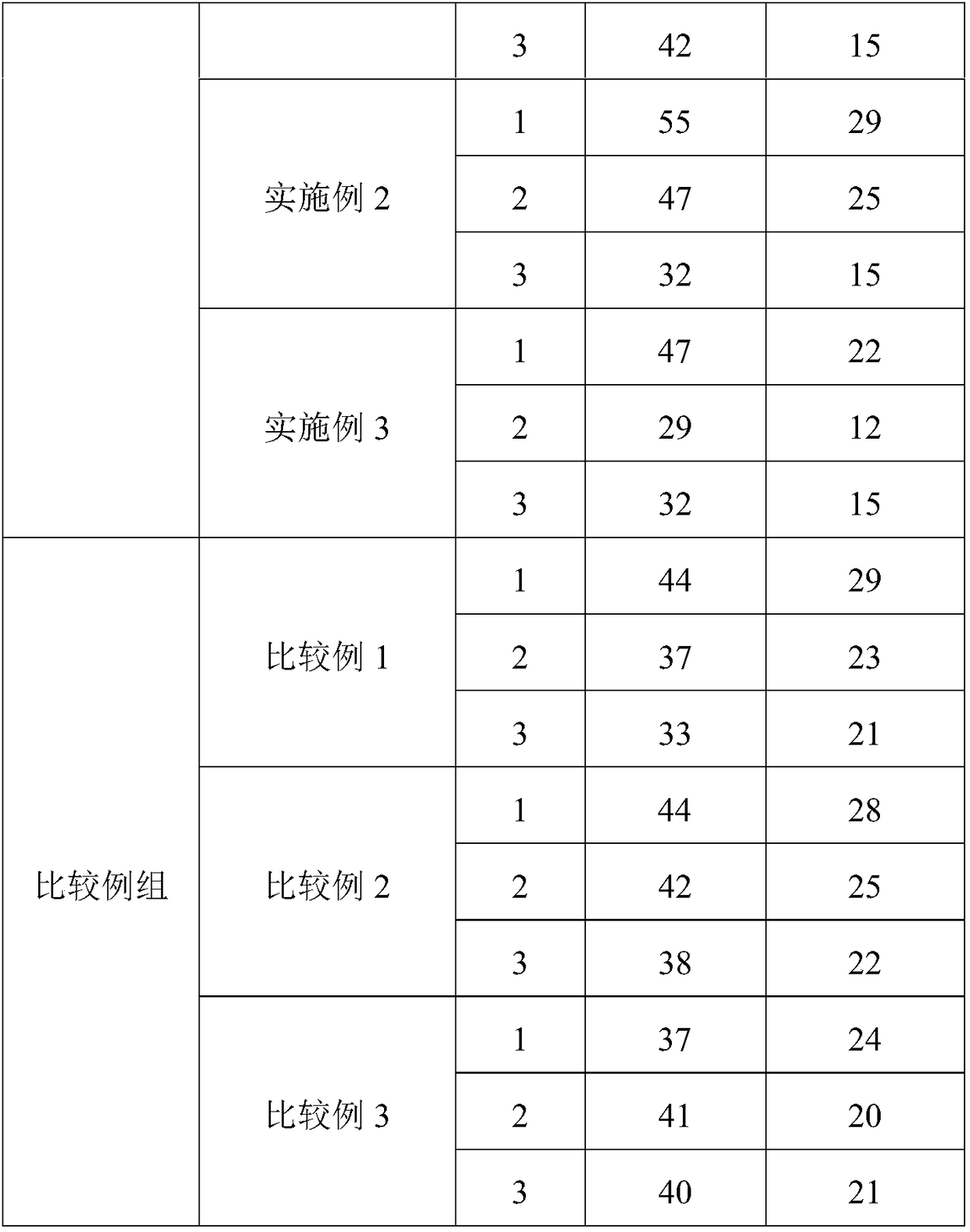

Examples

Embodiment 1

[0037] An anti-fungal and bacteriostatic agent for paper archives, which is prepared from the following raw materials in parts by weight: 50 parts of porous carbon material, 3 parts of sodium citrate, 1 part of anchovy powder, 2 parts of asarum powder, and 3 parts of pepper powder , 1 part of Radix japonica oil, 2 parts of chitosan, 1 part of gelatin.

[0038] The preparation method of the described paper archives antifungal and bacteriostatic agent comprises the following steps:

[0039] (1) The porous carbon material was refluxed in concentrated nitric acid at 80° C. for 2 hours, acidified, and then washed to neutrality for later use;

[0040] (2) Dissolve sodium citrate in acetic acid solution, add anchovy powder, Chinese prickly ash powder, asarum powder, Radix japonica oil, chitosan and porous carbon material, and perform high pressure homogenization after ultrasonic dispersion for 10 min. The pressure is 30MPa, and the homogenization time is 10min;

[0041] (3) adding ...

Embodiment 2

[0051] An anti-fungal and bacteriostatic agent for paper archives, which is made from the following raw materials in parts by weight: 88 parts of porous carbon materials, 5 parts of sodium citrate, 4 parts of anchovy powder, 4 parts of asarum powder, and 6 parts of pepper powder , 2 parts of Radix japonica oil, 6 parts of chitosan, and 3 parts of gelatin.

[0052] The preparation method of the described paper archives antifungal and bacteriostatic agent comprises the following steps:

[0053] (1) The porous carbon material was refluxed in concentrated nitric acid at 80°C for 3 hours, acidified, and then washed to neutrality for later use;

[0054] (2) Dissolve sodium citrate in acetic acid solution, add anchovy powder, Chinese prickly ash powder, asarum powder, Radix japonica oil, chitosan and porous carbon material, and perform high pressure homogenization after ultrasonic dispersion for 10 min. The pressure is 75MPa, and the homogenization time is 5min;

[0055] (3) adding...

Embodiment 3

[0065] An anti-fungal and bacteriostatic agent for paper archives, which is made from the following raw materials in parts by weight: 70 parts of porous carbon material, 4 parts of sodium citrate, 2 parts of anchovy powder, 3 parts of asarum powder, and 4 parts of pepper powder , 1.5 parts of arborvitae oil, 5 parts of chitosan, and 2 parts of gelatin.

[0066] Wherein, the preparation method of the porous carbon material is:

[0067] (1) prepare the sodium hydroxide solution that mass fraction is 7%, put the loofah into the sodium hydroxide solution and soak it for 5-10min, wherein, the mass ratio of the loofah to the sodium hydroxide solution is 1:15, then heated to Stir at 50°C for 30min, wash, dry and pulverize;

[0068] (2) take by weighing triethanolamine dodecyl sulfate, butyl acrylate and be dispersed in distilled water, then add the loofah powder obtained in step (1), the quality of triethanolamine dodecyl sulfate, butyl acrylate, loofah The ratio is 1: 1.5: 40, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com