Wing-shaped lead SOP (small outline package) device and technological method for forming leads of wing-shaped lead SOP device

A technology of leads and devices, which is applied in the field of safety and reliability of electronic components, can solve problems such as insufficient lead stress release space, insufficient stress release space, and failure to meet forming requirements, so as to reduce secondary damage, reduce failure rate, and improve forming efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

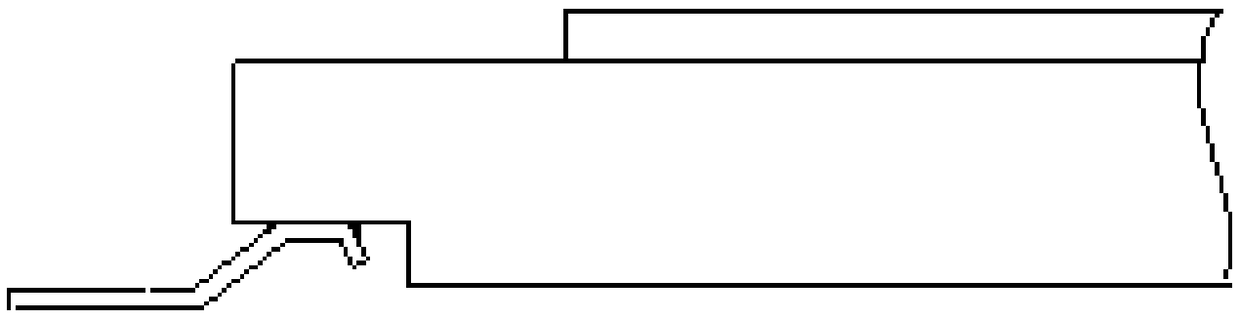

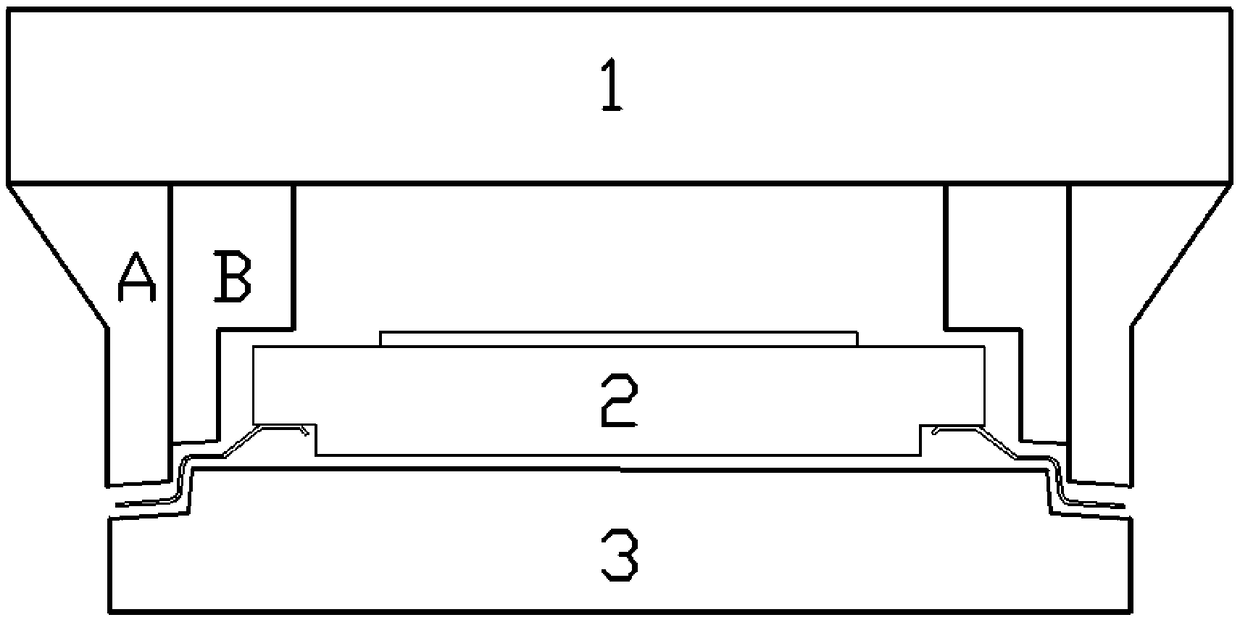

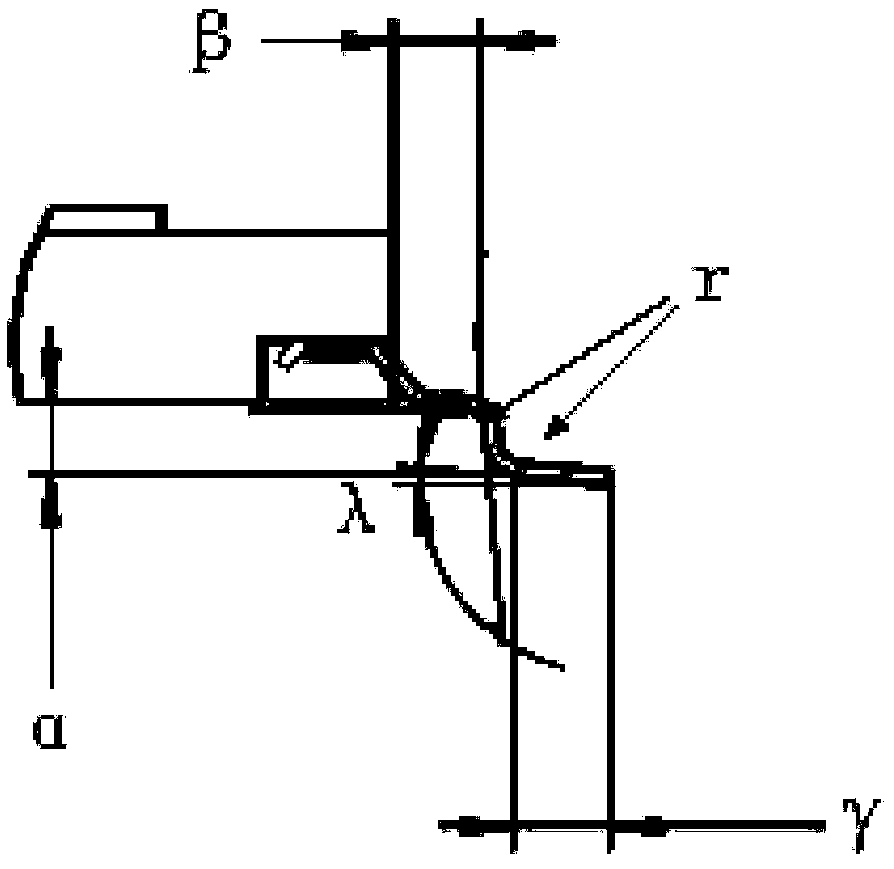

[0029] Such as figure 1 As shown, the domestic SOP package bottom lead-out device has the characteristics of the bottom lead-out type, the device lead stress relief bend is small, and the device lead length is short. These characteristics determine that this type of device 2 cannot meet the relevant forming requirements of QJ3171 "Technical Requirements for Forming Components of Aerospace Electronic and Electrical Products", and there is a risk of cracking and failure of solder joints under stress after direct welding.

[0030] At present, the common processing method for domestic SOP device leads is as follows: first straighten the device airfoil leads, and then reshape them according to the standard requirements. The disadvantage of this process method is that two operations are required, and the forming efficiency is low. At the same time, it is necessary to strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com