Wireless monitoring system for ripple compensator based on mobile terminal

A corrugated compensator and mobile terminal technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of strong corrosiveness of the working medium, complex external force of the corrugated compensator, easy failure, etc., to avoid loss and The effect of production accident, improving safety production coefficient, saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

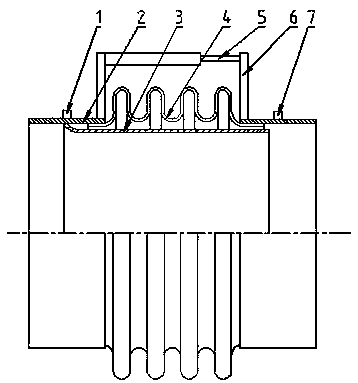

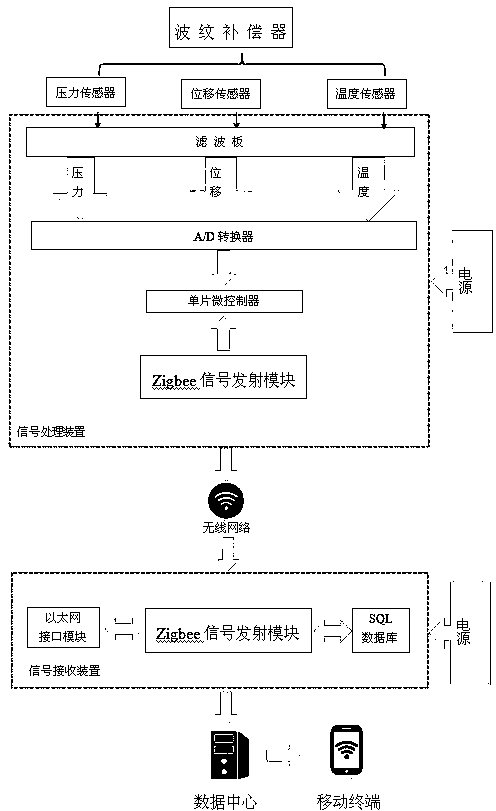

[0014] The invention consists of a pressure sensor, a temperature sensor, a displacement sensor, a signal processing device, a power supply, a signal receiving device and a mobile terminal. The signal processing device includes a filter board, an A / D converter, a single-chip microcontroller, a Zigbee signal transmitting module, and is powered by a power supply. The signal receiving device includes a Zigbee signal transmitting module, an Ethernet interface module, and a SQL database. For the measurement of the temperature, displacement and pressure of the corrugated compensator, the signal is converted and processed and uploaded to the server through the wireless communication network for transmission to the mobile terminal, and then transmitted to the remote monitoring host through the Internet for real-time monitoring and early warning.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com