High-efficiency grating coupler based on intermediate-refractive-index waveguide material and preparation method therefor

A grating coupler and refractive index technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of complex processing technology and low coupling diffraction efficiency, and achieve the effect of simple process steps, high diffraction coupling efficiency and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

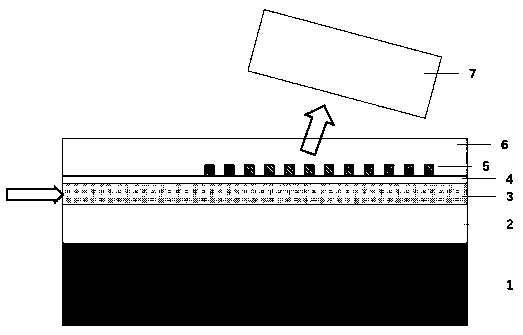

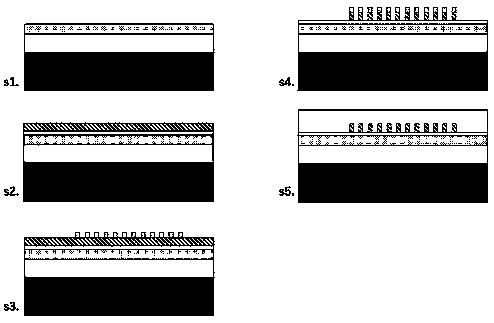

[0036] A high-efficiency grating coupler based on medium-refractive-index waveguide materials, please refer to figure 1 , including a substrate 1, a lower cladding layer 2, a medium refractive index material layer 3, an insulating layer 4, an amorphous silicon grating 5 and an upper cladding layer 6; wherein the structure of the grating coupler is the substrate 1 from bottom to top , a lower cladding layer 2, a medium refractive index material layer 3, an insulating layer 4, an amorphous silicon grating 5, and an upper cladding layer 6. The light is transmitted in the waveguide mode in the medium refractive index material 3. When the light is transmitted to the grating area, it is diffracted by the amorphous silicon grating 5, and the light wave satisfying the Bragg condition emerges at a specific angle and is collected by the single-mode fiber 7. On the contrary, the light injected by the single-mode fiber 7 is coupled into the waveguide 3 of medium refractive index material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com