Fuel gasification and combined cooling heating and power supply system and method for LNG power driven vessel

A marine fuel and supply system technology, applied in the direction of the loading system, hull ventilation/heating/cooling, oil supply devices, etc., can solve the problems of fuel gasification cold energy loss, impact on the marine environment, low-temperature damage to ships, etc., to achieve a wide range of The effect of applicability and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

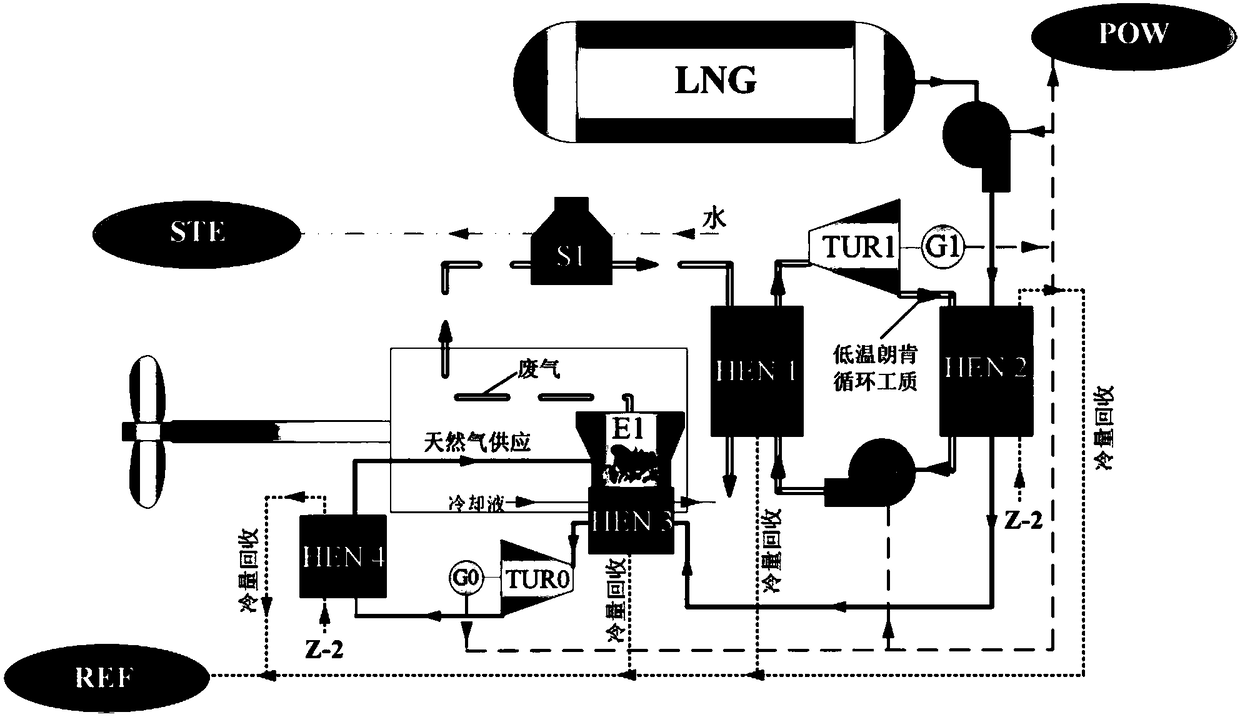

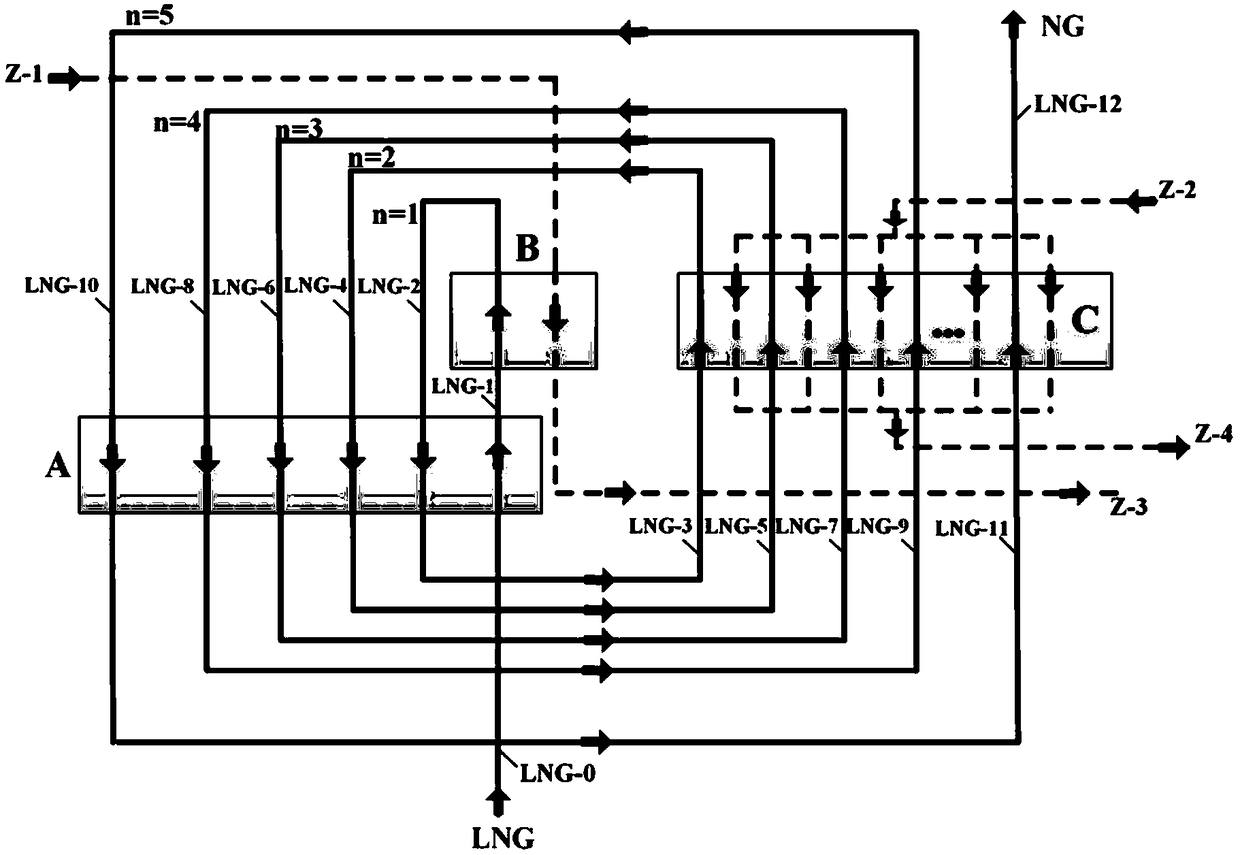

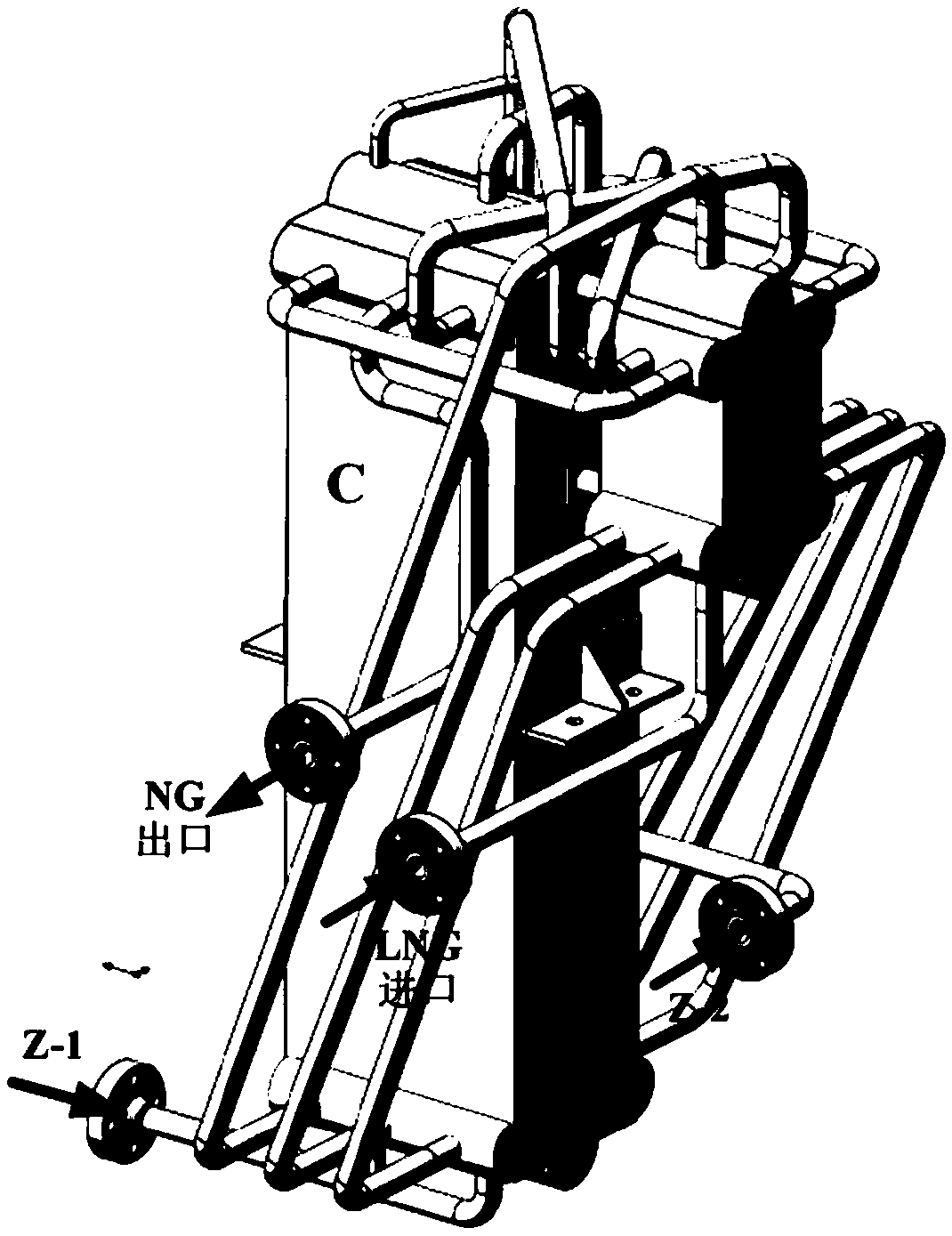

[0054] Such as figure 1 As shown, the LNG-powered marine fuel gasification and cooling, heating and power triple supply system includes LNG gasification and cooling capacity recovery unit, main engine exhaust gas heat recovery unit, low-temperature Rankine cycle unit, power generation unit, surplus cooling capacity recovery unit, and various Ship's steam, cooling and power supply passages connected between units;

[0055] The LNG gasification and cold recovery unit includes LNG liquid fuel storage tank LNG, liquid pump PUM0, first cycle heat exchange network HEN1, second cycle heat exchange network HEN2, third cycle heat exchange network HEN3, first The expander TUR0, the fourth cycle heat exchange network HEN4 and the ship engine E1; the LNG liquid fuel storage tank LNG is connected to the second cycle heat exchange network HEN2 through the liquid pump PUM0 and the low-temperature fuel supply channel, and the second cycle heat exchange network HEN2 and the first cycle heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com