Level control and drainage device

A drainage device and water level control technology, applied in water supply devices, flushing toilets, sanitary equipment for toilets, etc., can solve the problems of indetermination of the position of the shaft, the volume of the space occupied by the water tank, and small drainage gaps, etc., to avoid bacteria and Virus spread, bathroom space saving, water noise elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

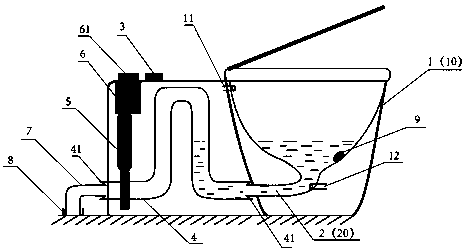

[0038] The embodiment of the present invention provides a water level control and drainage device, including a toilet body 1, a flush valve 3, a U-shaped pipe 4, a toilet sewage outlet 2, a sewage pipe connecting pipe 7, a motor 6, and an ultrasonic generator 9. Body 1 is a conventional prior art toilet, with an upper water outlet 11 at the inner side wall of the upper end, and a lower water outlet 12 at the inner side of the lower end aligned with the center of the toilet sewage outlet 2; Protruding spring sealing ring 41, one end of which is in sealing and movable connection with the toilet sewage outlet 2, and the other end is in sealing and moving connection with the sewage pipe connecting pipe 7, and the spring sealing ring 41 can be rotated more than 1 million times to maintain the sealing degree; One end of the U-shaped pipe 4 is provided with a transmission device 5, which can be one or more combinations of transmission structures such as gears, transmission shafts, and...

specific Embodiment approach 2

[0043]The embodiment of the present invention provides a water level control and drainage device, which is basically the same as the specific embodiment 1, except that it is not the toilet sewage discharge and cleaning, but the washbasin sewage discharge and cleaning, including corresponding to the toilet body 1 in the specific embodiment 1 Washbasin body 10, washbasin drain outlet 20 corresponding to toilet drain outlet 2, U-shaped pipe 4, transmission device 5, sewage pipe connecting pipe 7, motor 6 or manual rotary valve 61, ultrasonic generator 9. The bottom of the washbasin basin body 10 is provided with a washbasin drain outlet 20, and at least one circle of protruding spring sealing ring 41 is respectively installed on the walls at both ends of the U-shaped pipe 4, and one end of the U-shaped pipe 4 is connected to the washbasin drain outlet 20. Sealed movable connection, the other end is sealed and movable connected with the sewage pipe connecting pipe 7; one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com