Slope strengthening method based on plant urease reinforcing liquid

A technology of plant urease and reinforcement liquid is applied in the field of slope reinforcement, and the field of slope reinforcement based on plant urease reinforcement liquid can solve the problems of high cost, poor effect, difficult construction and maintenance, etc., and achieves low cost, simple treatment method, and engineering Effects with easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Slope reinforcement process

[0026] (1) First, use sand to make a slope with a top surface width of 20cm, a length of 40cm, a height of 20cm, and a slope ratio of 1:1 in the model box, such as figure 1 (make two identical slopes, one without any treatment, as a control group);

[0027] (2) Grind the dried soybeans into soybean powder, and pass through a 100-mesh sieve for later use (dried at low temperature and sealed for storage to prevent deterioration).

[0028] (3) Preparation of treatment powder: Mix urea and calcium chloride at a molar ratio of 1:1 (prepared immediately to prevent deterioration of the reagent).

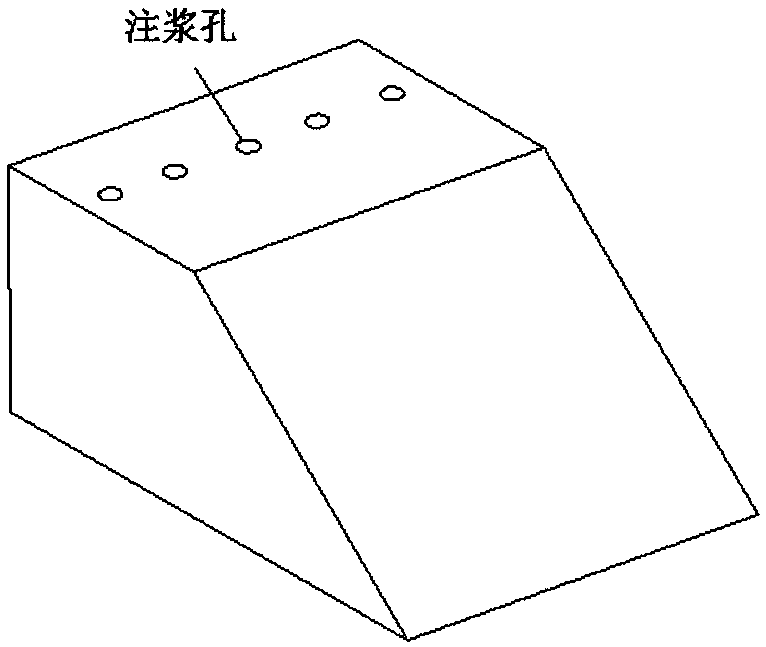

[0029] (4) Insert 5 plastic pipes with a diameter of 2 cm from the top of the slope along the width and length direction at intervals, the distance between each plastic pipe is 10 cm, and take out the plastic pipe and the internal soil to make a grouting hole ,Such as figure 2 ;

[0030] (5) Preparation of plant urease reinforcement solution: Wei...

Embodiment 2

[0038] (1) First, use sand to make a slope with a top surface width of 20cm, a length of 40cm, a height of 20cm, and a slope ratio of 1:1 in the model box, such as figure 1 ;

[0039] (2) Grind the dried soybeans into soybean powder, and pass through a 100-mesh sieve for later use (dried at low temperature and sealed for storage to prevent deterioration).

[0040] (3) Preparation of treatment powder: Mix urea and calcium chloride at a molar ratio of 1:2 (prepared for current use to prevent deterioration of the reagent).

[0041] (4) Insert 5 plastic pipes with a diameter of 2 cm from the top of the slope along the width and length direction at intervals, the distance between each plastic pipe is 10 cm, and take out the plastic pipe and the internal soil to make a grouting hole ,Such as figure 2 ;

[0042] (5) Preparation of plant urease reinforcement solution: Weigh soybean flour and treated powder with a mass ratio of 1:2, and add a certain amount of water according to th...

Embodiment 3

[0046] (1) First, use sand and soil in the model box to make a slope with a top surface width of 20cm, a length of 40cm, a height of 20cm, and a slope ratio of 1:1, such as figure 1 ;

[0047] (2) Grind the dried soybeans into soybean powder, and pass through a 100-mesh sieve for later use (dried at low temperature and sealed for storage to prevent deterioration).

[0048] (3) Preparation of treatment powder: Mix urea and calcium chloride at a molar ratio of 2:1 (prepared for use now to prevent deterioration of the reagent).

[0049] (4) Insert 5 plastic pipes with a diameter of 2 cm from the top of the slope along the width and length direction at intervals, the distance between each plastic pipe is 10 cm, and take out the plastic pipe and the internal soil to make a grouting hole ,Such as figure 2 ;

[0050] (5) Preparation of plant urease reinforcement solution: Weigh soybean flour and treated powder of equal mass, and add a certain amount of water according to the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com