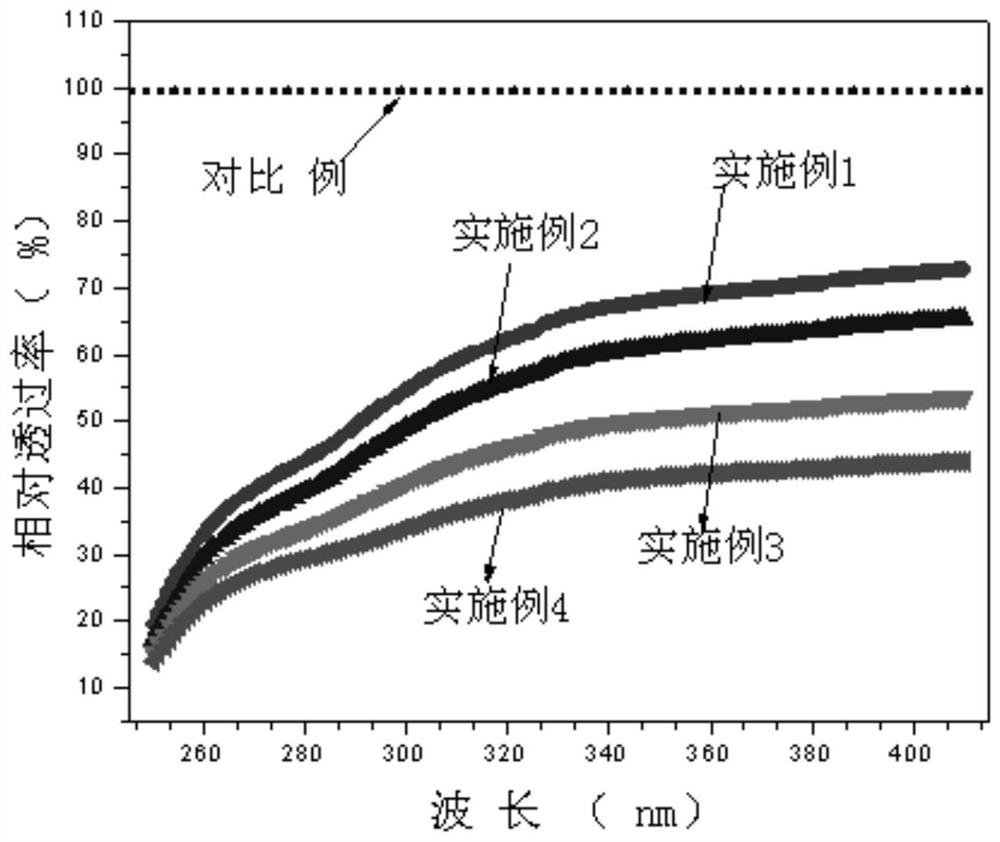

Preparation method of polyurethane coating for textiles comprising nanofiller and Coptis chinensis extract

A polyurethane coating and nano-filler technology, which is applied in textiles and papermaking, etc., achieves the effects of large specific surface, high surface energy, and clean and environmentally friendly preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

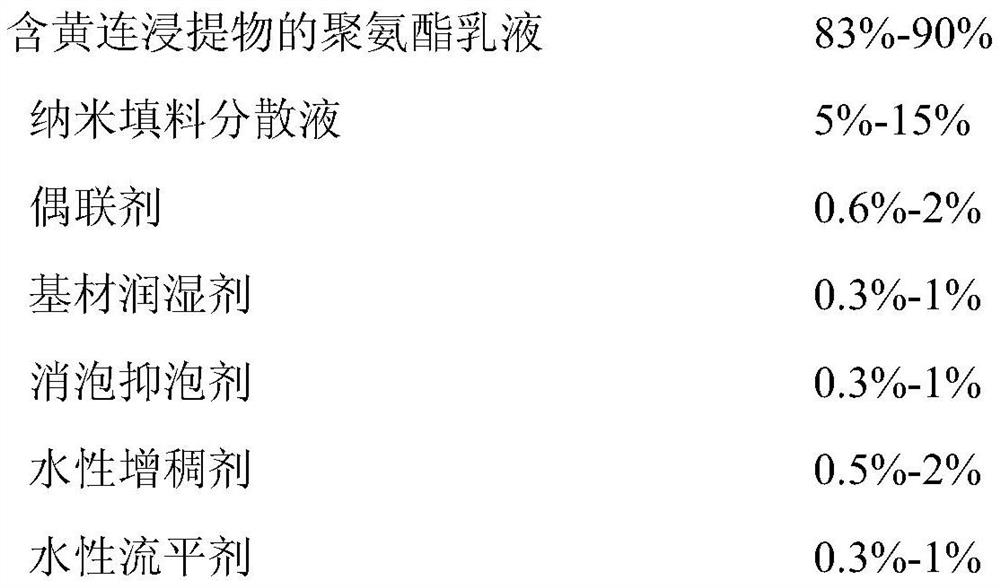

[0034] The formula composition of coating is as follows:

[0035]

[0036] The method of preparation is as follows:

[0037] (1) Melt and mix 10g of dihydric alcohol (YMER N-120) containing non-ionic hydrophilic groups in the side chain and 90g of polytetrahydrofuran diol (PTMG 3K, Mn=3000) at a temperature of 58°C, and pass through a vacuum of 0.09MPa , Dehydration treatment at a temperature of 128°C, molar ratio n NCO / n OH Add 24.0 g of diisocyanate (HDI) at about 3.8, and react at a temperature of 98 ° C for 115 min to obtain a polyurethane prepolymer (a);

[0038] (2) Add 6.0 g of dimethylol butyric acid (DMBA) and 8 g of solvent DMF to the polyurethane prepolymer (a), control the temperature at 92° C. to continue the reaction for 140 min, and add 3.2 g of a salt-forming agent (triethylamine) to obtain water dispersible polyurethane prepolymer (b);

[0039] (3) Disperse the polyurethane prepolymer (b) in 205 g of the prepared Coptis chinensis extract under high-spe...

Embodiment 2

[0042] The formula composition of coating is as follows:

[0043]

[0044] The method of preparation is as follows:

[0045] (1) Melt and mix 10g of dihydric alcohol (YMER N-120) containing non-ionic hydrophilic groups in the side chain and 80g of polytetrahydrofuran diol (PTMG 2K, Mn=2000) at a temperature of 53°C, and pass through a vacuum of 0.08MPa , Dehydration treatment at a temperature of 123°C, molar ratio n NCO / n OH Add 35.0 g of diisocyanate (IPDI) at about 3.3, and react at a temperature of 93 ° C for 105 min to obtain a polyurethane prepolymer (a);

[0046] (2) Add 5.0 g of dimethylol butyric acid (DMBA) and 10 g of solvent DMF to the polyurethane prepolymer (a), control the temperature at 85° C. to continue the reaction for 120 min, and add 2.56 g of a salt-forming agent (triethylamine) to obtain water dispersible polyurethane prepolymer (b);

[0047] (3) Disperse the polyurethane prepolymer (b) in 185 g of the prepared Coptis chinensis extract under high-...

Embodiment 3

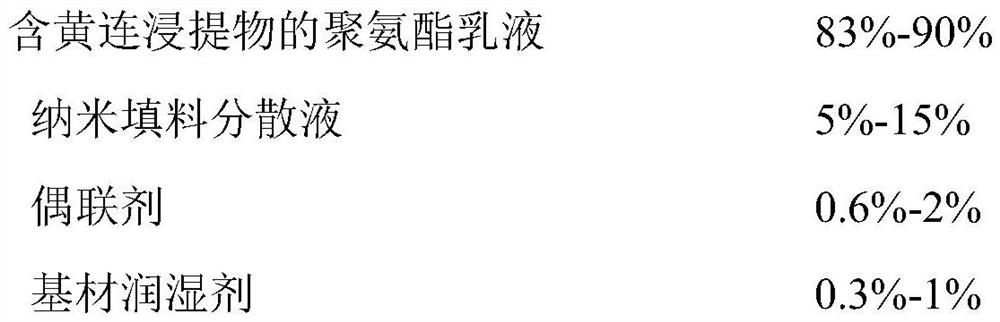

[0050] The formula composition of coating is as follows:

[0051]

[0052] The method of preparation is as follows:

[0053] (1) Melt and mix 13g of dihydric alcohol (YMER N-120) containing non-ionic hydrophilic groups in the side chain and 87g of polytetrahydrofuran diol (PTMG 2K, Mn=2000) at a temperature of 47°C, and pass through a vacuum of 0.07MPa , Dehydration treatment at a temperature of 117°C, molar ratio n NCO / n OH Add 33.5g of diisocyanate (IPDI) at about 2.8, and react at a temperature of 87°C for 97min to obtain a polyurethane prepolymer (a);

[0054] (2) Add 2.8 g of dimethylolpropionic acid (DMPA) and 14 g of solvent DMF to the polyurethane prepolymer (a), control the temperature at 77° C. to continue the reaction for 90 min, and add 1.4 g of a salt-forming agent (triethylamine) to obtain water dispersible polyurethane prepolymer (b);

[0055] (3) Disperse the polyurethane prepolymer (b) in 168 g of the prepared Coptidis rhizome extract under high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com