Electrochemical in situ leaching of serpentine using membranes for simultaneous mg 2+ archive co 2 device and method

A membrane electrochemistry, serpentine technology, applied in the direction of electrolysis components, electrolysis process, etc., to achieve the effect of easy control and use, simple device structure, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

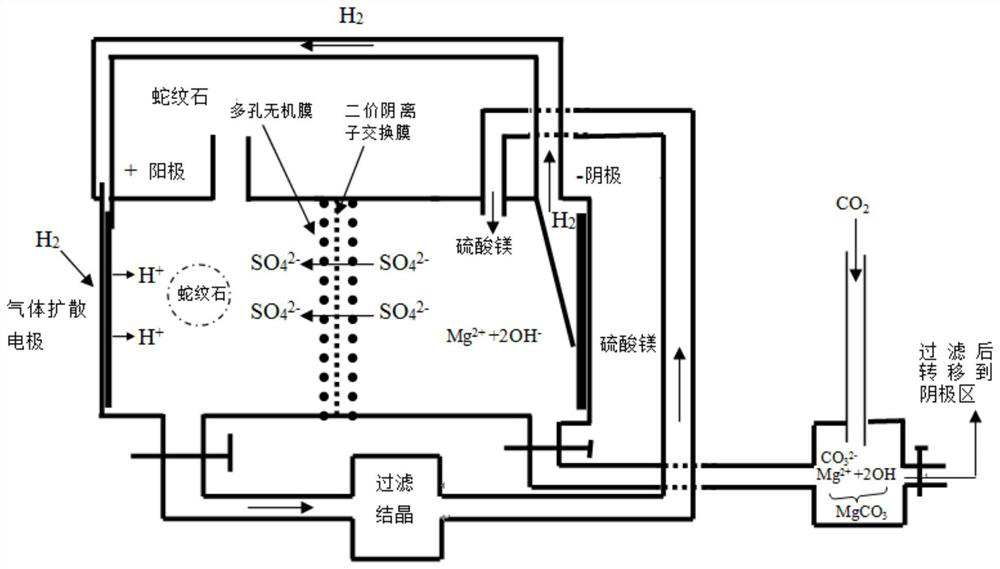

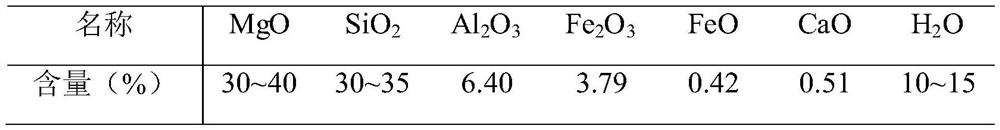

[0050] In this example, see figure 1 , a membrane electrochemical in situ leaching of serpentine with simultaneous Mg 2+ Storage of CO 2 The device is characterized in that: an anion exchange membrane is used to divide the reaction tank into an anode area and a cathode area, and the anion exchange membrane used allows anion ions to pass through, while cations are blocked; the electrode in the anode area adopts a gas diffusion electrode, and the electrode in the cathode area Made of any one of stainless steel and graphite or a composite of the two;

[0051] According to the ratio of solid-liquid mass to volume in the range of 0.1:10 (g / mL) to 1:1 (g / mL), put the pre-activated serpentine with a particle size of 60-200 mesh into the anode area of membrane electrochemistry In the acidic system solution, the serpentine-acidic solution mixed system solution is formed. After the reaction starts, the following membrane electrochemical reactions will occur in the two poles:

[005...

Embodiment 2

[0071] This embodiment is basically the same as Embodiment 1, especially in that:

[0072] In this example, a membrane electrochemical in situ leaching of serpentine while Mg 2+ Storage of CO 2 method, including the following steps:

[0073] According to the ratio of solid-liquid mass to volume ratio of 1:1 (g / mL), the pre-activated serpentine with a particle size of 60 mesh is put into the anode tank solution in the anode area of membrane electrochemistry for reaction, and the reaction temperature is controlled. The temperature is 10°C, the reaction time is 500min, and an anode tank solution containing serpentine is formed, and the stirring speed of the anode tank solution is 100rpm;

[0074] H through the anode diffusion electrode 2 The flow rate is controlled from 1sccm to 1000sccm, the cell voltage is controlled at 1V, and the current density is controlled at 1A / cm 2 ;Put the porous inorganic membrane on both sides of the anion exchange mold, so as to avoid the anion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com