Method for treating salt lake brine by using serpentine

A technology of salt lake brine and serpentine, applied in the direction of magnesium carbonate, etc., can solve the problems of high energy consumption and high cost, and achieve the effect of low energy consumption, low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

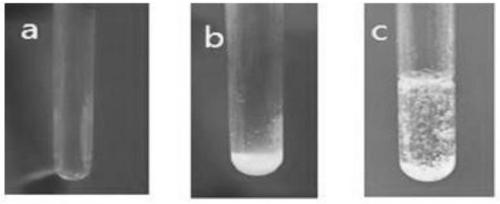

Examples

Embodiment 1

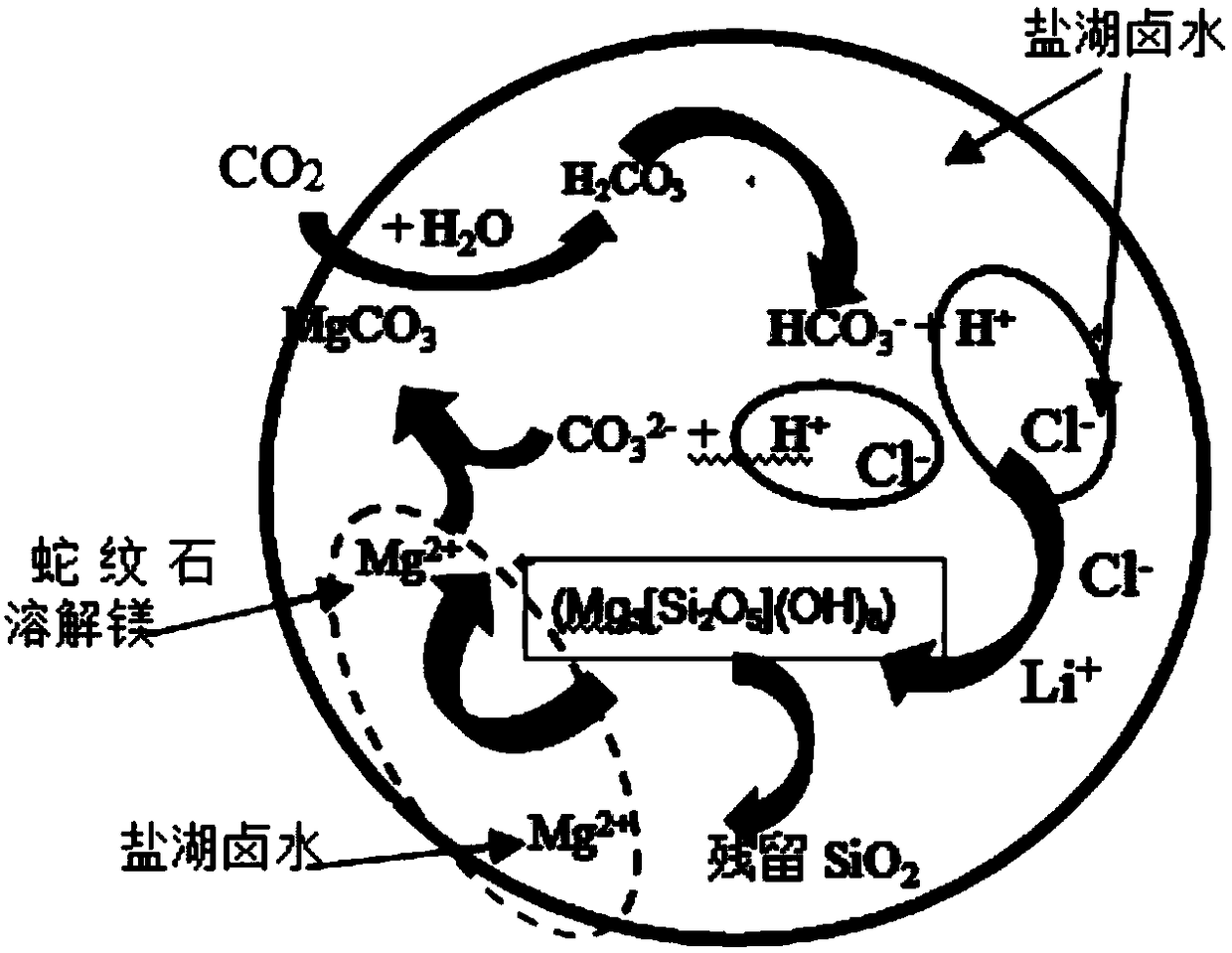

[0044] In this example, see figure 1 , utilize serpentine to process the method for saline lake brine, comprise the steps:

[0045] a. Serpentine pretreatment:

[0046] After the serpentine is crushed, it is ground in a planetary ball mill for 1 hour at a speed of 300r / min, and ball milling is carried out, and the sieve hole size is 200 mesh to obtain the ball milled pretreated serpentine powder, and then the serpentine powder is processed in a muffle furnace Then heat and calcine at 700° C. for 15 minutes to obtain calcined pre-activated serpentine powder;

[0047] b. Mineralization coupled reaction process:

[0048] Mix the 20g pretreated serpentine powder and 140ml salt lake brine after the treatment in the step a, and add it into the autoclave; CO 2 , forming serpentine-salt lake brine-CO 2 Reactant system solution, controlling the CO above the surface of the reactant system solution 2 The equilibrium pressure is 10Mpa, the temperature is controlled at 40°C, the reac...

Embodiment 2

[0058] This embodiment is basically the same as Embodiment 1, especially in that:

[0059] In the present embodiment, utilize serpentine to process the method for saline lake brine, comprises the steps:

[0060] a. Serpentine pretreatment:

[0061] After the serpentine is crushed, it is ground in a planetary ball mill for 5 hours at a speed of 300r / min, and ball milling is carried out, and the sieve size of the sieve is 300 mesh to obtain the ball milled pretreated serpentine powder, and then the serpentine powder is processed in a muffle furnace Then heat and calcine at 500° C. for 240 minutes to obtain calcined pre-activated serpentine powder;

[0062] b. Mineralization coupled reaction process:

[0063] Mix the 20g pretreated serpentine powder and 500ml salt lake brine after the treatment in the step a, and add it to the autoclave; CO 2 , forming serpentine-salt lake brine-CO 2 Reactant system solution, controlling the CO above the surface of the reactant system soluti...

Embodiment 3

[0069] This embodiment is basically the same as the previous embodiment, and the special features are:

[0070] In the present embodiment, utilize serpentine to process the method for saline lake brine, comprises the steps:

[0071] a. Serpentine pretreatment:

[0072] After the serpentine is crushed, it is ground in a planetary ball mill for 3 hours at a speed of 300r / min, and ball milling is carried out, and the sieve hole size is 100 mesh to obtain the ball milled pretreated serpentine powder, and then the serpentine powder is processed in a muffle furnace Then heat and calcine at 800° C. for 15 minutes to obtain calcined pre-activated serpentine powder;

[0073] b. Mineralization coupled reaction process:

[0074] Mix the 20g pretreated serpentine powder and 20ml salt lake brine after the treatment in the step a, and add it to the autoclave; CO 2 , forming serpentine-salt lake brine-CO 2 Reactant system solution, controlling the CO above the surface of the reactant sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com