Powdery material preheating pneumatic transmission device and technology

A technology for pneumatic conveying and powdery materials, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of large engineering volume and investment, long conveying distance, poor material fluidity, etc. The effect of smooth material conveying and saving the consumption of conveying gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

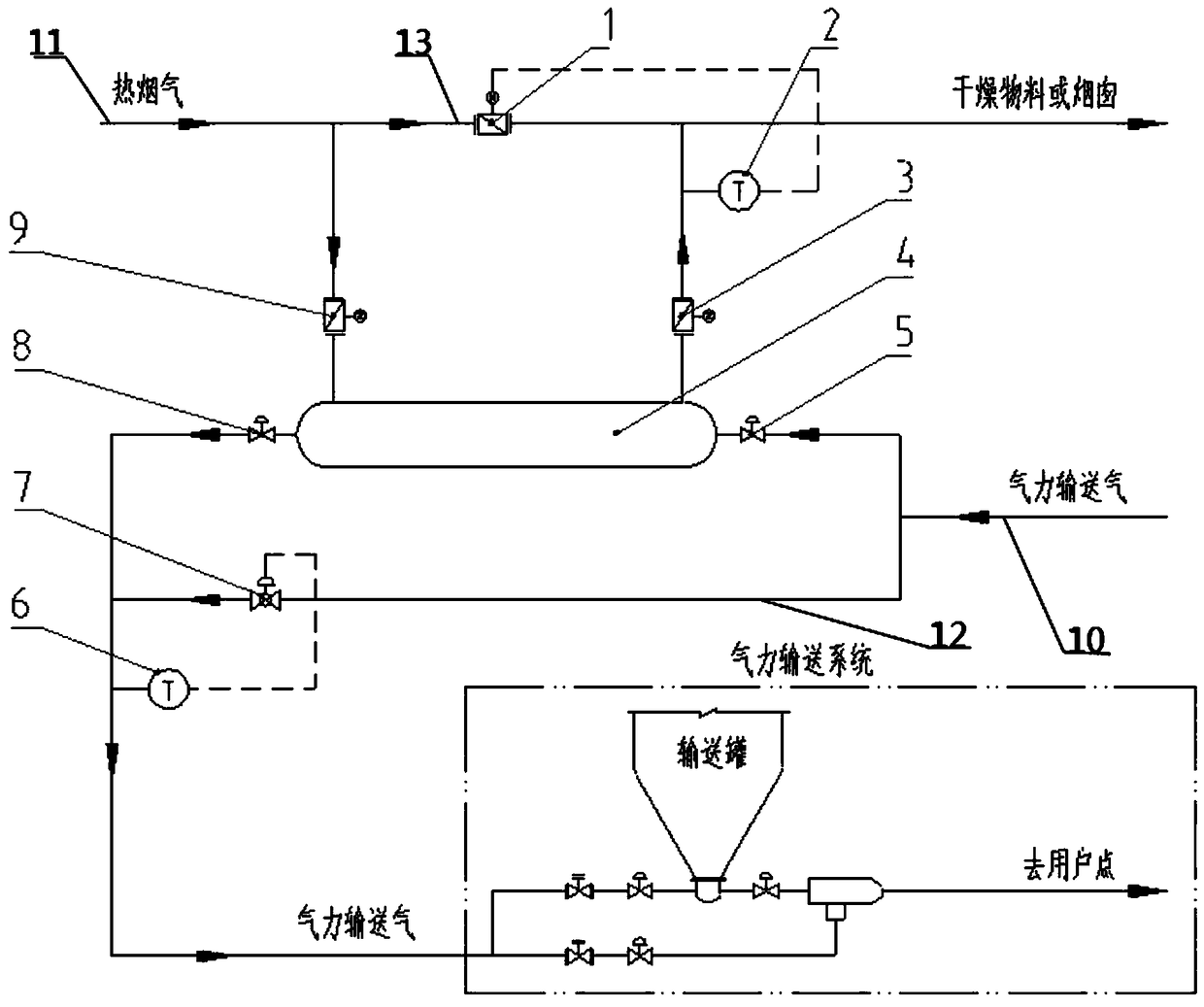

[0027] Attached below figure 1 The specific embodiment of the present invention is further described:

[0028] Such as figure 1 As shown, a powder material preheating pneumatic conveying device includes a preheater 4 , a pneumatic conveying gas pipeline 10 and a hot flue gas pipeline 11 .

[0029] The pneumatic conveying gas pipeline 10 is divided into two branches, one branch is the pneumatic conveying gas preheating branch, the pneumatic conveying gas preheating branch passes through the preheater 4, and the other branch is the pneumatic conveying gas bypass pipe 12, the two The branches merge into a main pipeline at the outlet of the preheater 4, leading to the pneumatic conveying system.

[0030] The hot flue gas pipeline 11 is divided into two branches, one branch is the hot flue gas preheating branch, the hot flue gas preheating branch passes through the preheater 4, the other branch is the flue gas bypass pipe 13, two The road merges into a main pipeline at the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com