Pressing die and pressing method for vinylidene fluoride impeller with movable ring

A difluoro impeller and pressing mold technology, which is applied in the field of pressing molds for partial difluoro impellers, can solve problems such as temperature sensitivity, low yield, and large shrinkage, and achieve reliable and stable fastening, high production efficiency, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

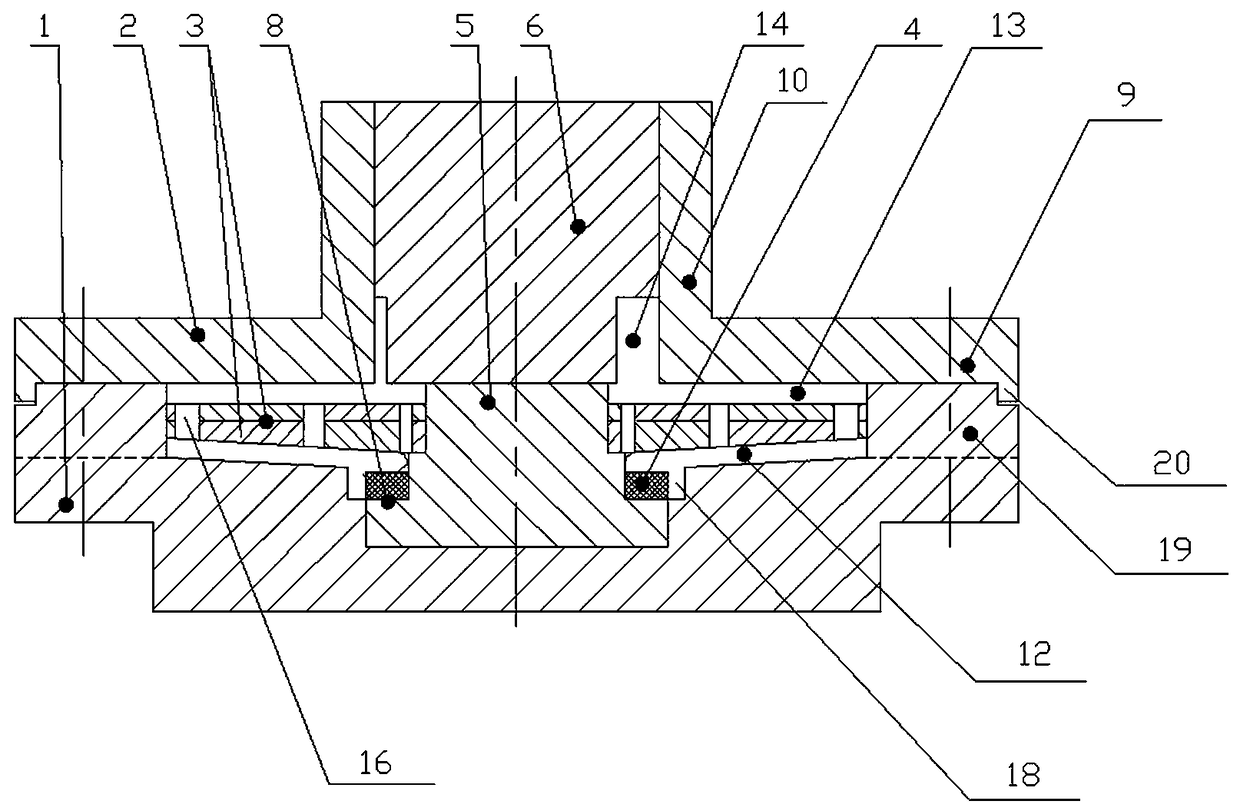

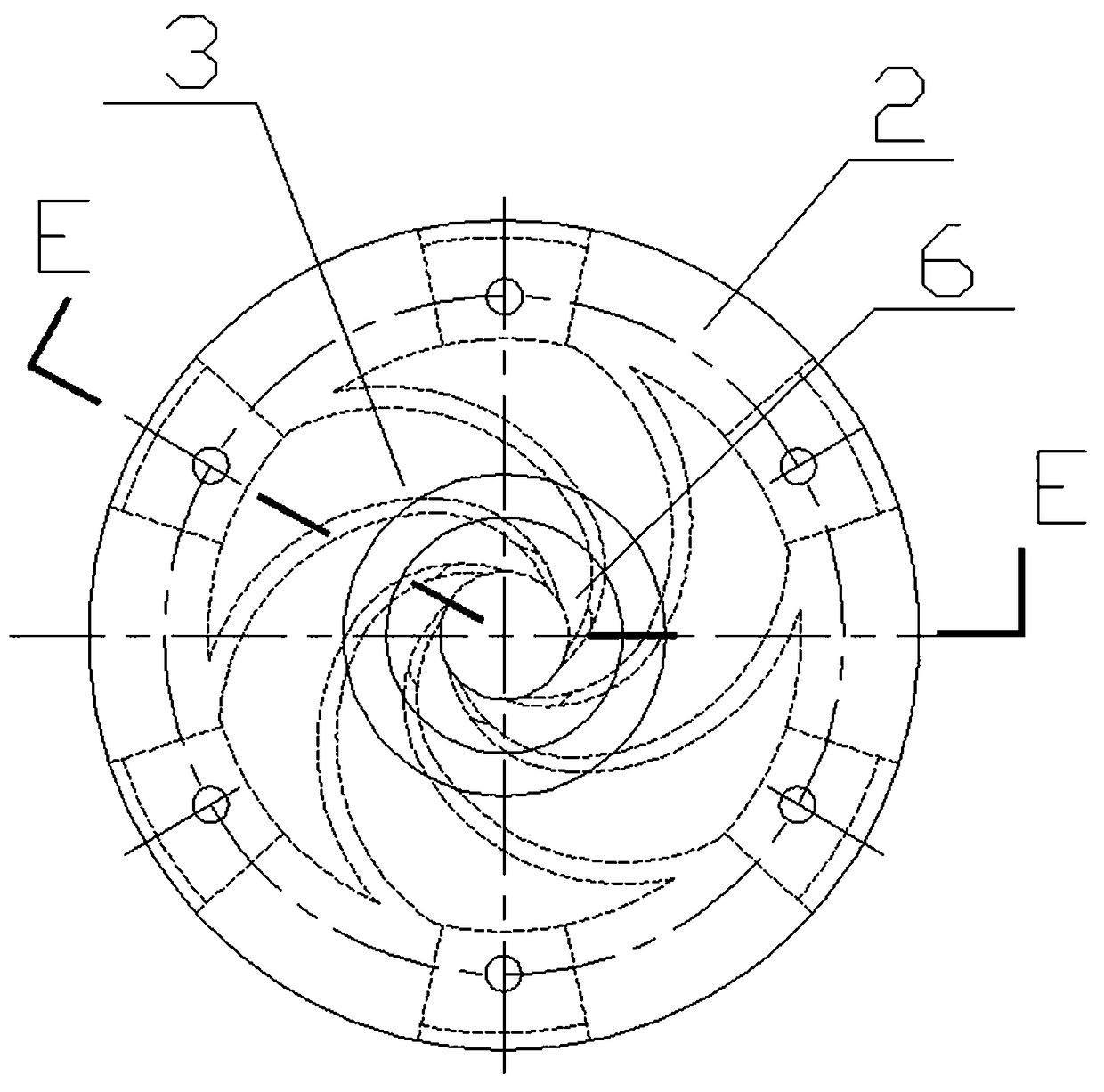

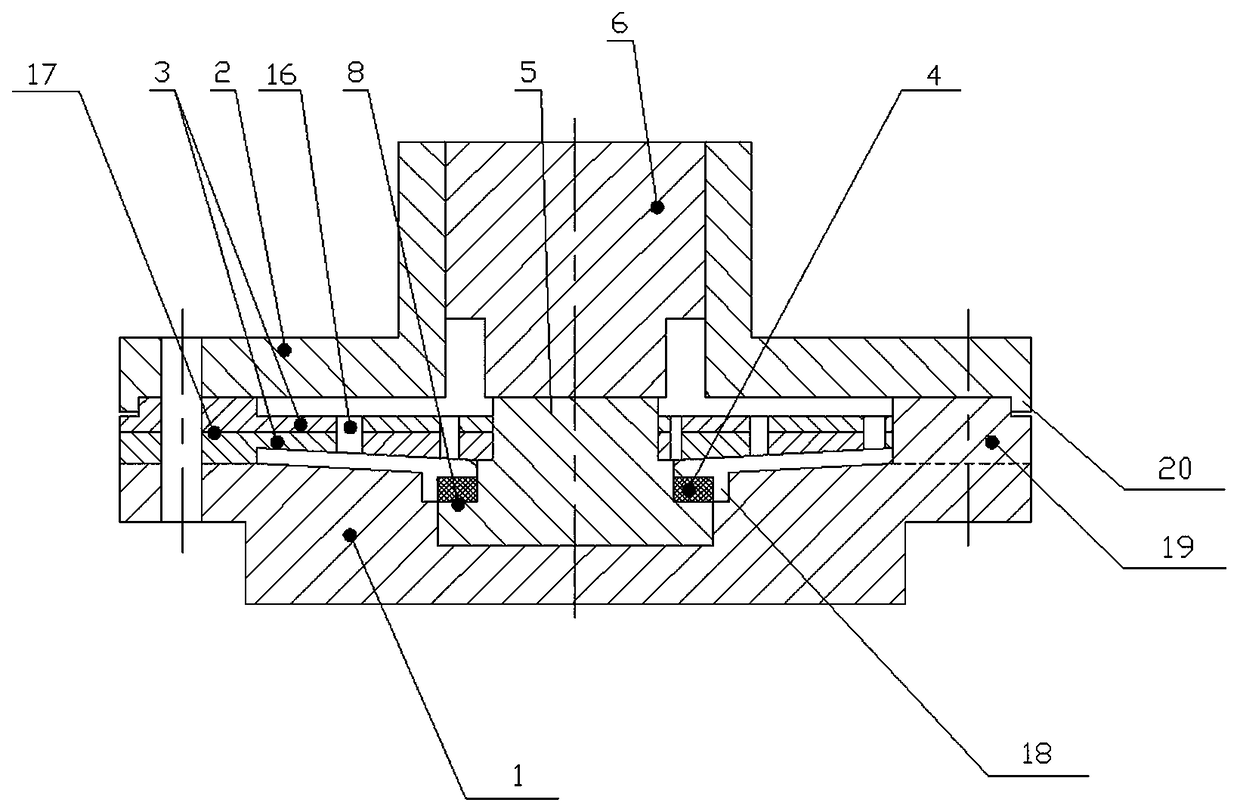

[0046] Embodiment 1 (taking the impeller of the CQB32-25-160F series pump as an example):

[0047] A method for pressing a partial difluoride impeller with a driving ring, comprising the following steps:

[0048] (1) Select a copper plate as the feeding plate. The length of the feeding plate is 360mm, the width is 270mm, the height is 65mm, and the thickness of the chassis of the feeding plate is 2mm. And wipe the surface of the feeding tray with a release agent, the release agent is composed of silicone oil and rubber water in a mass ratio of 1:10. Afterwards, take 330 g of partial difluoride pellets and add the partial difluoride pellets into the feeding pan to ensure that the partial difluoride pellets are evenly distributed in the feed tray and the distribution height of the partial difluoride pellets is 10 mm.

[0049] (2) Use the release agent to wipe the upper inner surface of the bottom mold 1, the impeller plug 3, the inner side of the barrel 2 and the lower part of ...

Embodiment 2

[0055] Embodiment 2 (taking the impeller of the CQB50-32-160F series pump as an example):

[0056] A method for pressing a partial difluoride impeller with a driving ring, comprising the following steps:

[0057] (1) Select a copper plate as the feeding plate. The length of the feeding plate is 370mm, the width is 280mm, the height is 70mm, and the thickness of the chassis of the feeding plate is 2.5mm. And wipe the surface of the feeding tray with a release agent, the release agent is composed of silicone oil and rubber water in a mass ratio of 1:10. Afterwards, take 520 g of partial difluoride pellets and add the partial difluoride pellets into the feeding pan to ensure that the partial difluoride pellets are evenly distributed in the feed tray and the distribution height of the partial difluoride pellets is 11 mm.

[0058] (2) Use the release agent to wipe the upper inner surface of the bottom mold 1, the impeller plug 3, the inner side of the barrel 2 and the lower part o...

Embodiment 3

[0064] Embodiment 3 (taking the impeller of the CQB80-65-160F series pump as an example):

[0065] A method for pressing a partial difluoride impeller with a driving ring, comprising the following steps:

[0066] (1) Select a copper plate as the feeding plate. The length of the feeding plate is 380mm, the width is 290mm, the height is 75mm, and the thickness of the chassis of the feeding plate is 3mm. And wipe the surface of the feeding tray with a release agent, the release agent is composed of silicone oil and rubber water in a mass ratio of 1:10. After that, take 730g of partial difluoride pellets and add the partial difluoride pellets into the feeding pan to ensure that the partial difluoride pellets are evenly distributed in the feed tray and the distribution height of the partial difluoride pellets is 12 mm.

[0067] (2) Use the release agent to wipe the upper inner surface of the bottom mold 1, the impeller plug 3, the inner side of the barrel 2 and the lower part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com