High-pressure jet-flow nozzle and high-pressure jet-flow crushing device using same

A high-pressure jet and nozzle technology, applied in grain processing and other directions, can solve the problems of increasing the particle size distribution of materials, affecting the pulverization effect, and damaging the components of the jet flow channel, so as to enhance the sealing effect and achieve the effect of expanding production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

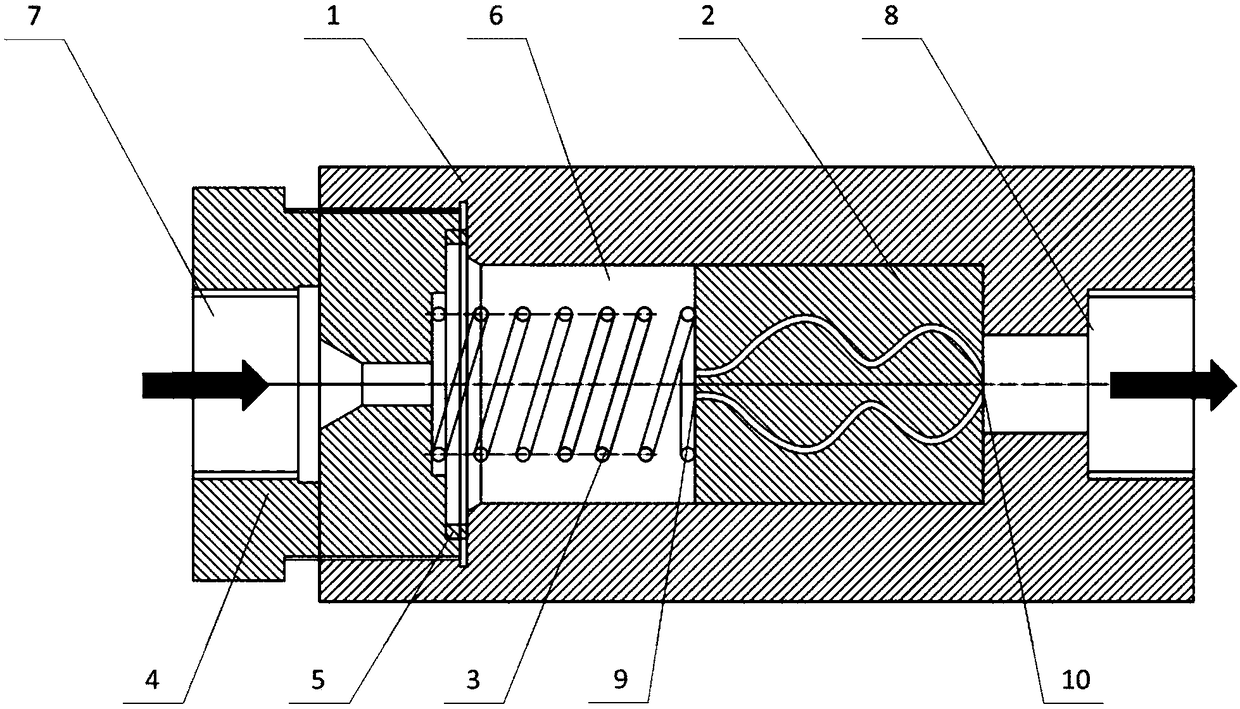

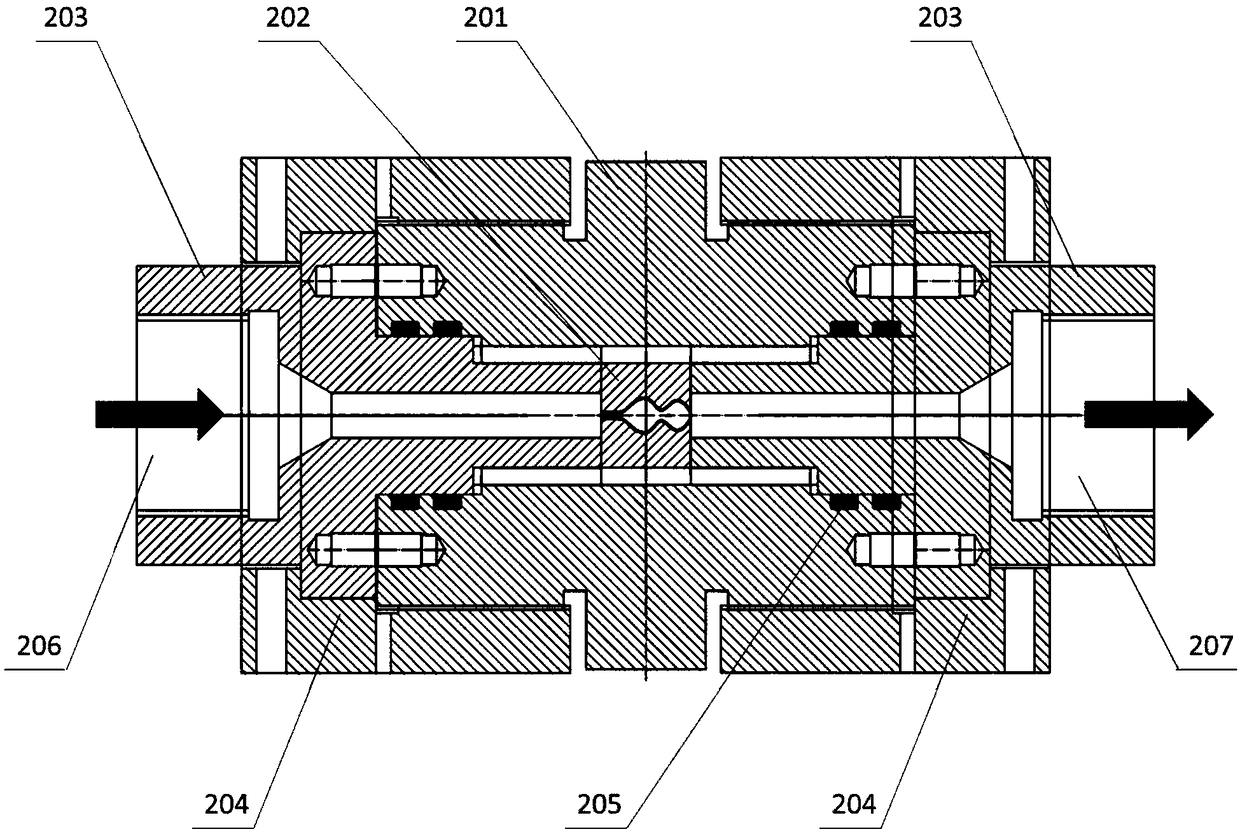

[0037] A high-pressure jet nozzle, such as figure 1As shown, it includes a stainless steel shell 1, a jet flow channel part 2, a stainless steel spring 3, a sealing cover 4, a sealing ring 5, and a buffer chamber 6. The sealing cover 4 is provided with a first liquid inlet 7, and one end of the housing 1 is provided with The first liquid outlet 8, the other end is fastened to the sealing cover 4, and the sealing ring 5 is arranged between the sealing cover 4 and the housing 1; the jet channel part 2 is arranged in the housing 1, and one end is provided with a second liquid inlet port 9, and the other end is provided with a second liquid outlet 10; the elastic component 3 is arranged between the jet flow path component 2 and the sealing cover 4, and the sealing cover 4 compresses the elastic component 3 when tightened, and the elastic component 3 compresses to generate elasticity The force fixes the jet channel part 2 and the housing 1; the buffer cavity 6 is formed by surround...

Embodiment 2

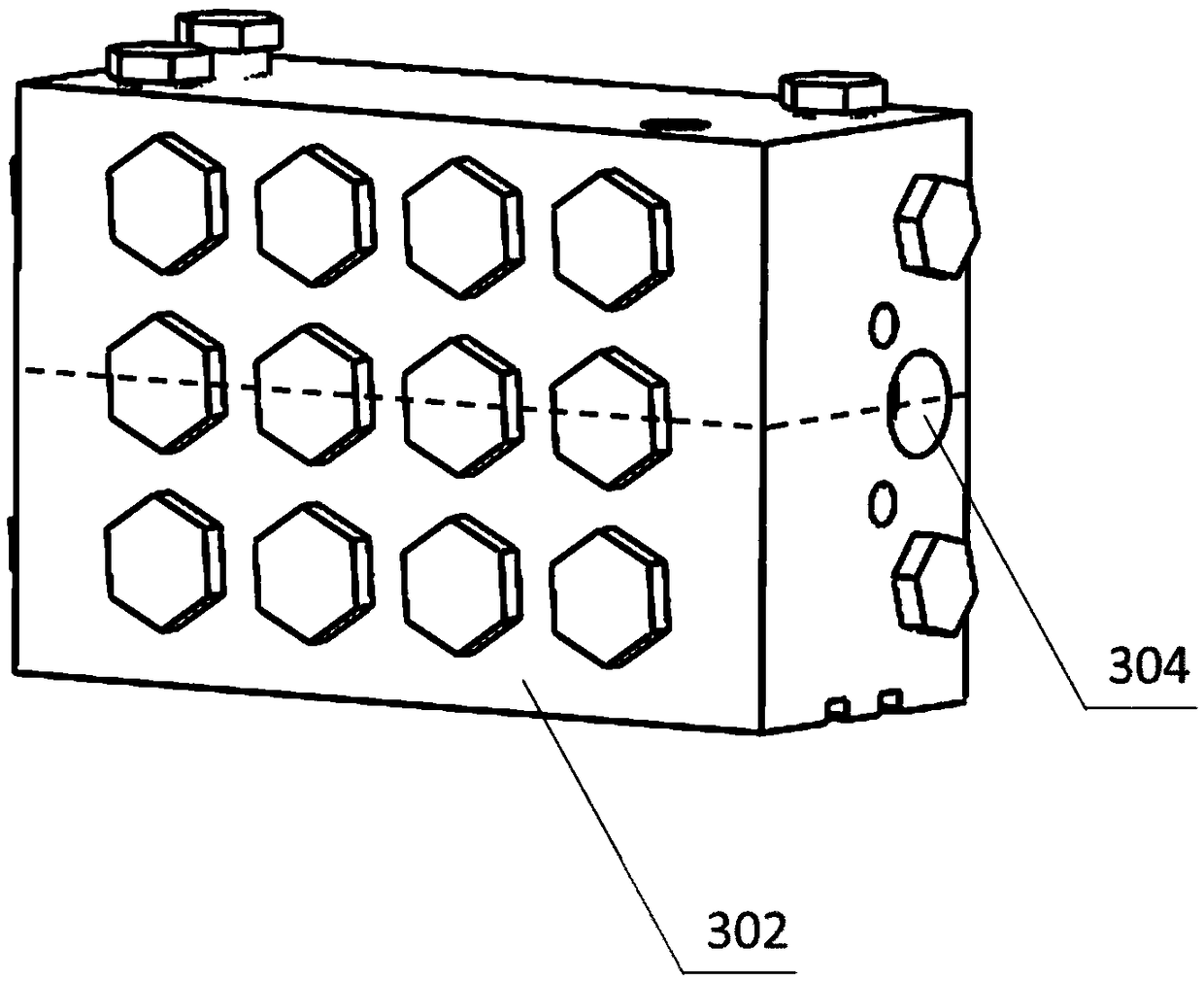

[0048] A high-pressure jet nozzle module, such as image 3 As shown, where the cross-sectional view is shown in Figure 4 shown. It includes a high-pressure jet nozzle structure 301 , an integrated housing 302 , a liquid inlet 303 , and a liquid outlet 304 . The structure of the high-pressure jet nozzle is basically the same as the high-pressure jet nozzle in Example 1, except that the position of the first liquid inlet is changed from being arranged on the sealing cover to being arranged on the side wall of the buffer chamber shell, and the buffer chambers are connected to each other. Unified feed from the liquid inlet 303. The first liquid outlets of each high-pressure jet nozzle structure are also communicated with each other.

[0049] It can be seen that, compared with the comparative example, Example 2 can conveniently realize the expansion of production capacity on the same overall structure.

[0050] When the high-pressure jet nozzle module of this embodiment is cru...

Embodiment 3

[0052] A high-pressure jet nozzle, such as Figure 5 shown. Compared with the high-pressure jet nozzle in Embodiment 1, it also includes two sets of sealing rings 11, one of which is arranged between the side wall of the jet flow path part 2 and the housing 1, and the other set is arranged on the side wall of the jet flow path part 2. Between the rear end face and the housing 1. The addition of two sets of sealing rings can better achieve sealing, and at the same time reduce the requirements for machining accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com