Combined truncated cone type gas-liquid redistributor

A redistributor, truncated cone technology, applied in the field of combined truncated cone gas-liquid redistributor, can solve the problems of uneven distribution of gas-liquid two-phase, lower efficiency of packed tower, lower mass transfer efficiency, etc. distribution, increasing contact area and time, and improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

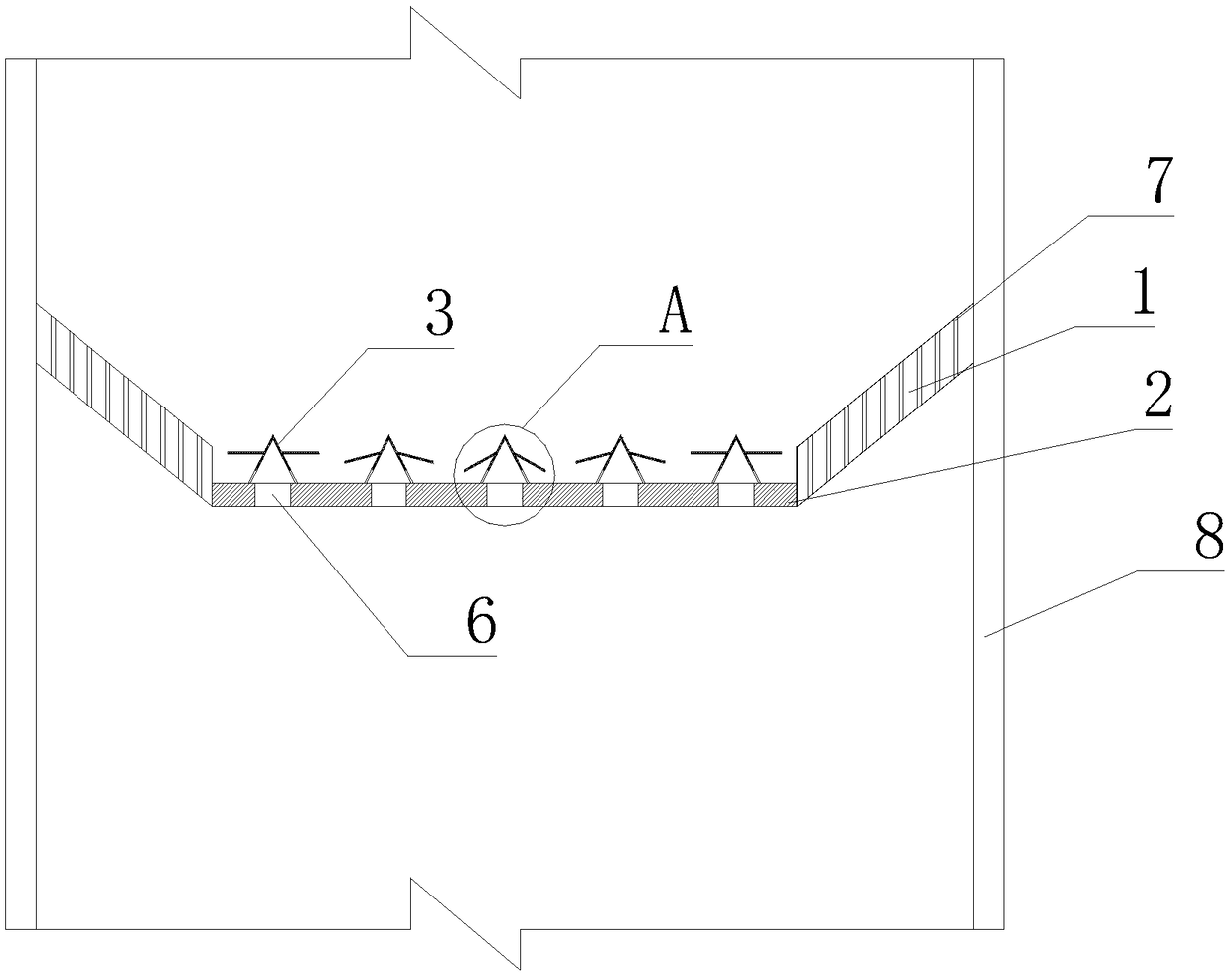

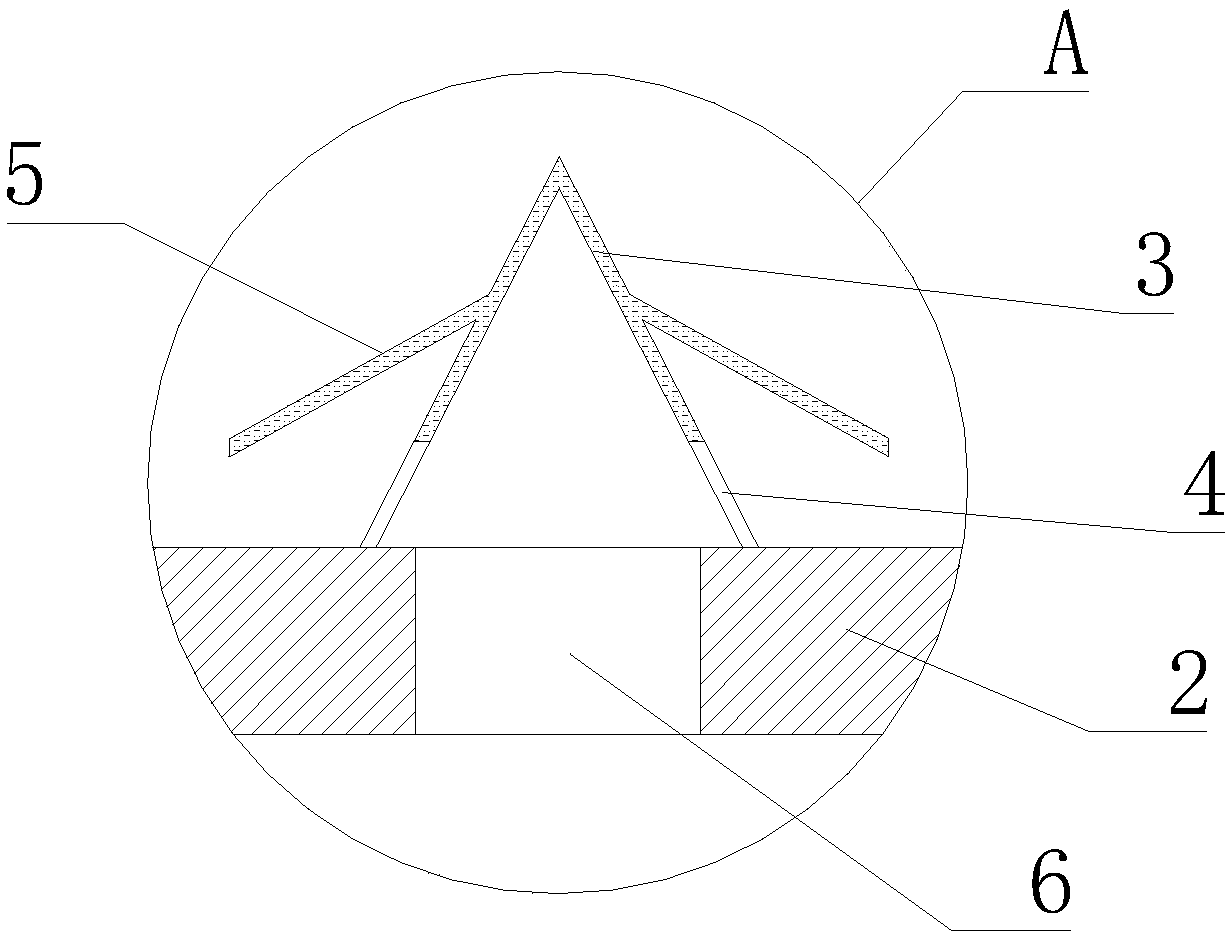

[0019] Please refer to figure 2 , the embodiment of the present invention discloses a combined truncated cone type gas-liquid redistributor, including a conical wall 1 and a connecting bottom plate 2, the outer diameter of the top of the conical wall 1 is larger than the outer diameter of the bottom, and it is an inverted frustum-shaped structure , the top of the conical wall 1 is fixed on the inner wall of the packed tower 8, and several second through holes 7 are evenly arranged on the conical wall 1, which are used for the gas flowing upward in the packed tower 8 to pass through, and are also used for packing The scrubbing liquid flowing downwards in the tower 8 passes through to complete the mutual mass transfer between gas and liquid;

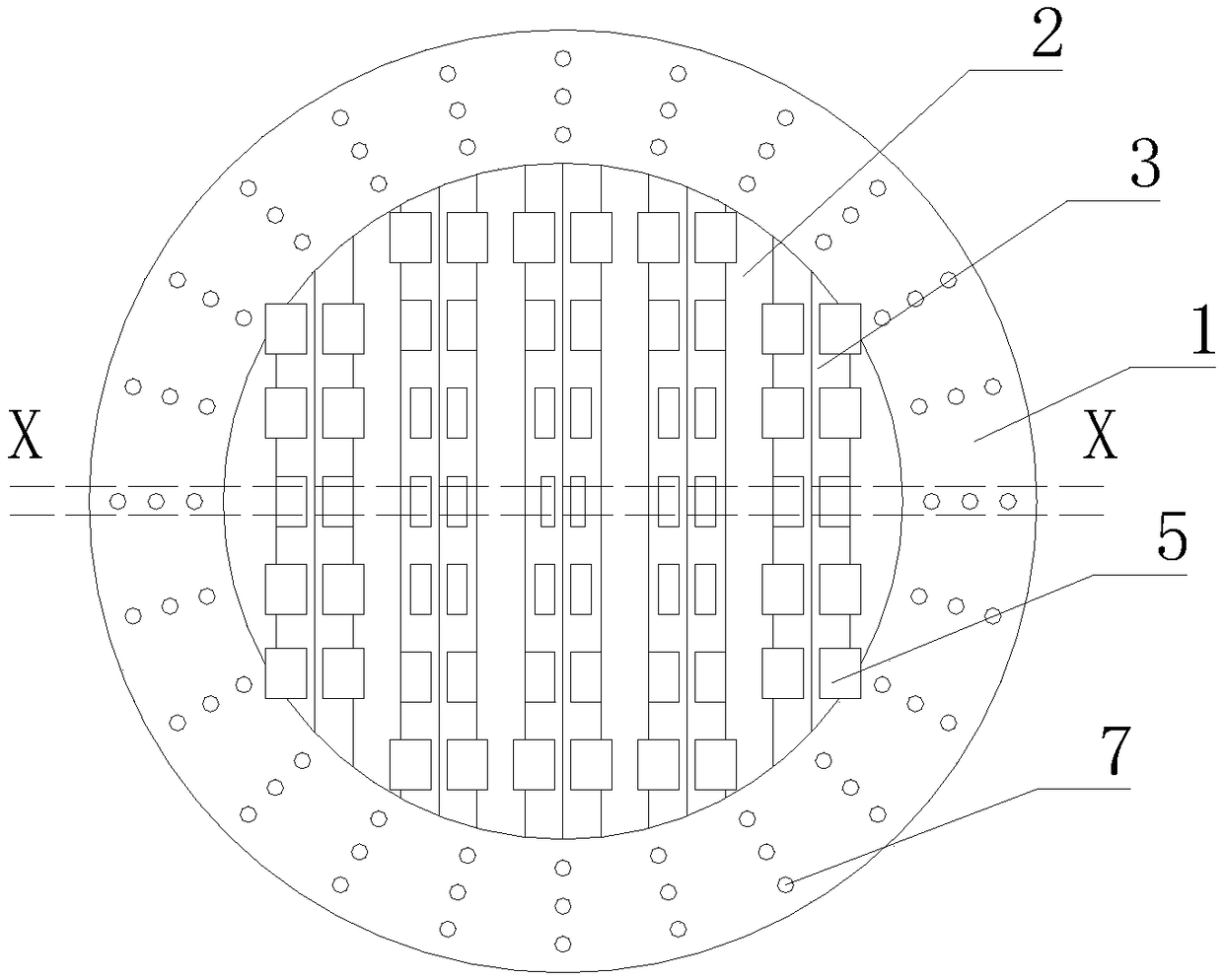

[0020] Please refer to figure 1 , figure 2 and image 3 , the bottom of the tapered wall 1 is provided with the connection bottom plate 2, when installing, keep the connection bottom plate 2 in a horizontal state, the connection botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com