Natural gas fuel cell power generation system and method adopting supercritical CO2 bottom cycle

A fuel cell and power generation system technology, applied in the direction of fuel cells, fuel cell additives, electrochemical generators, etc., can solve the problems of low bottom cycle efficiency, achieve simple system, reduce equipment volume, and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail.

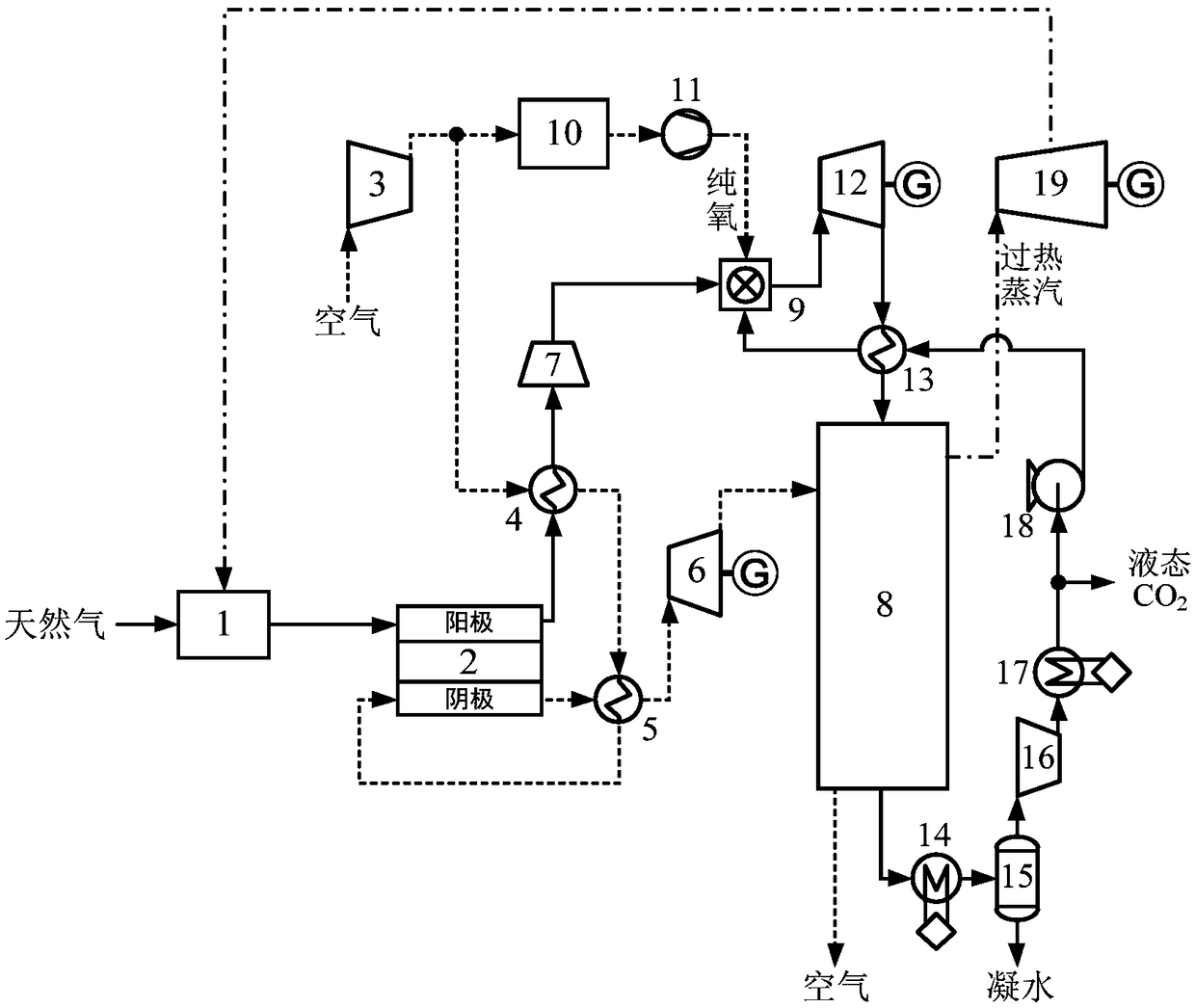

[0030] Such as figure 1 As shown, the invention provides a kind of using supercritical CO 2 Bottom cycle natural gas fuel cell power generation system, including fuel reformer 1, fuel cell 2, cathode air compressor 3, anode regenerator 4, cathode regenerator 5, air turbine 6, compressor 7, waste heat boiler 8 , pure oxygen burner 9, cryogenic air separation unit 10, oxygen compressor 11, CO2 Gas turbine 12, regenerator 13, tail gas condenser 14, gas-water separator 15, CO 2 Compressor 16, CO 2 Condenser 17, CO 2 A booster pump 18 and a steam turbine 19, wherein the outlet of the fuel reformer 1 is connected to the anode inlet of the fuel cell 2, the anode tail gas outlet of the fuel cell 2 is connected to the hot side inlet of the anode regenerator 4, and the heat of the anode regenerator 4 The side outlet is connected to the inlet of the pure oxygen burner 9 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com