Wide low frequency acoustic absorber with folding space

An absorber and low-frequency technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of single-frequency sound absorption and poor sound absorption effect, and achieve the effects of high sound absorption performance, widening sound absorption spectrum, and high sound wave reflection index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

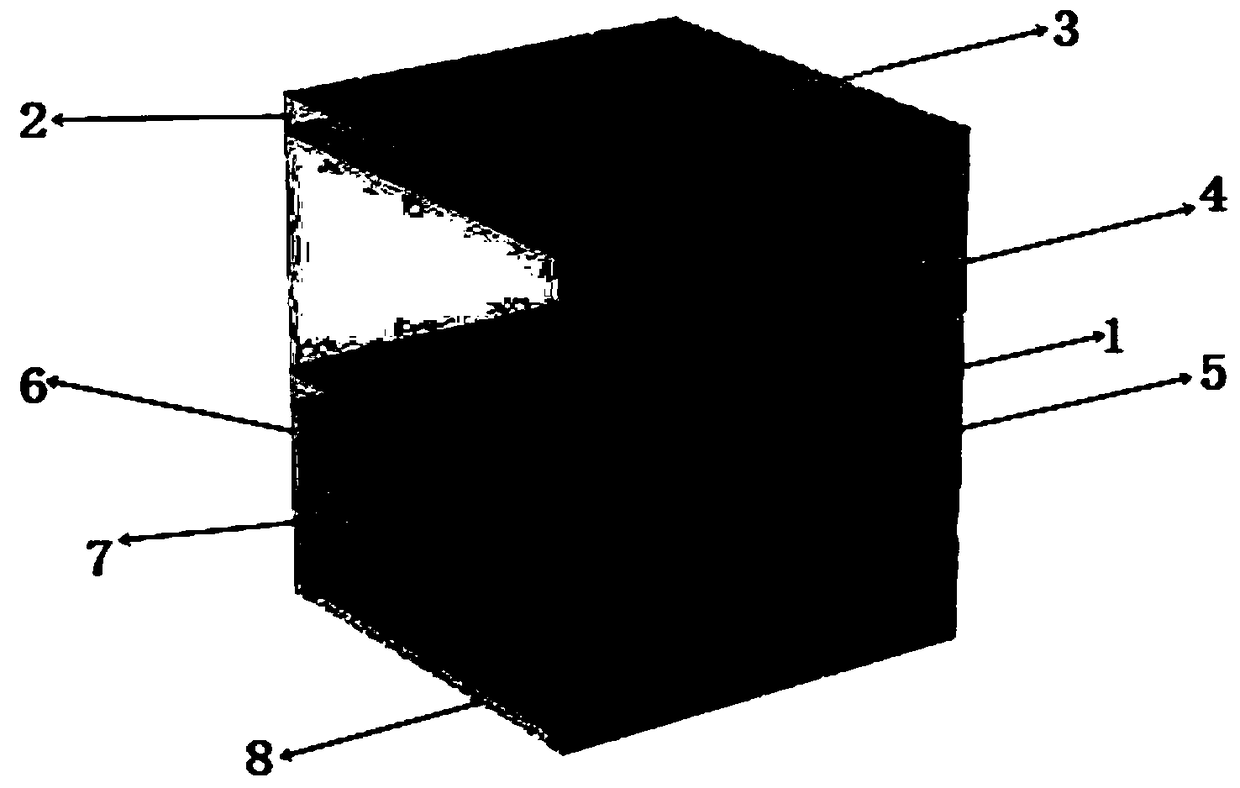

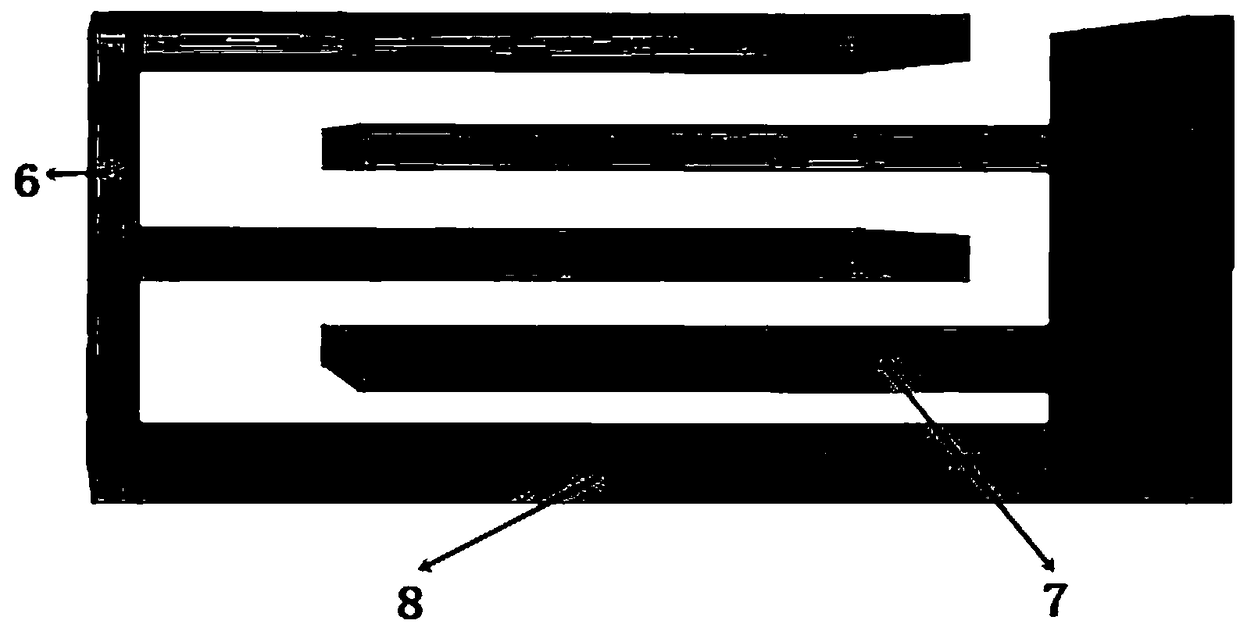

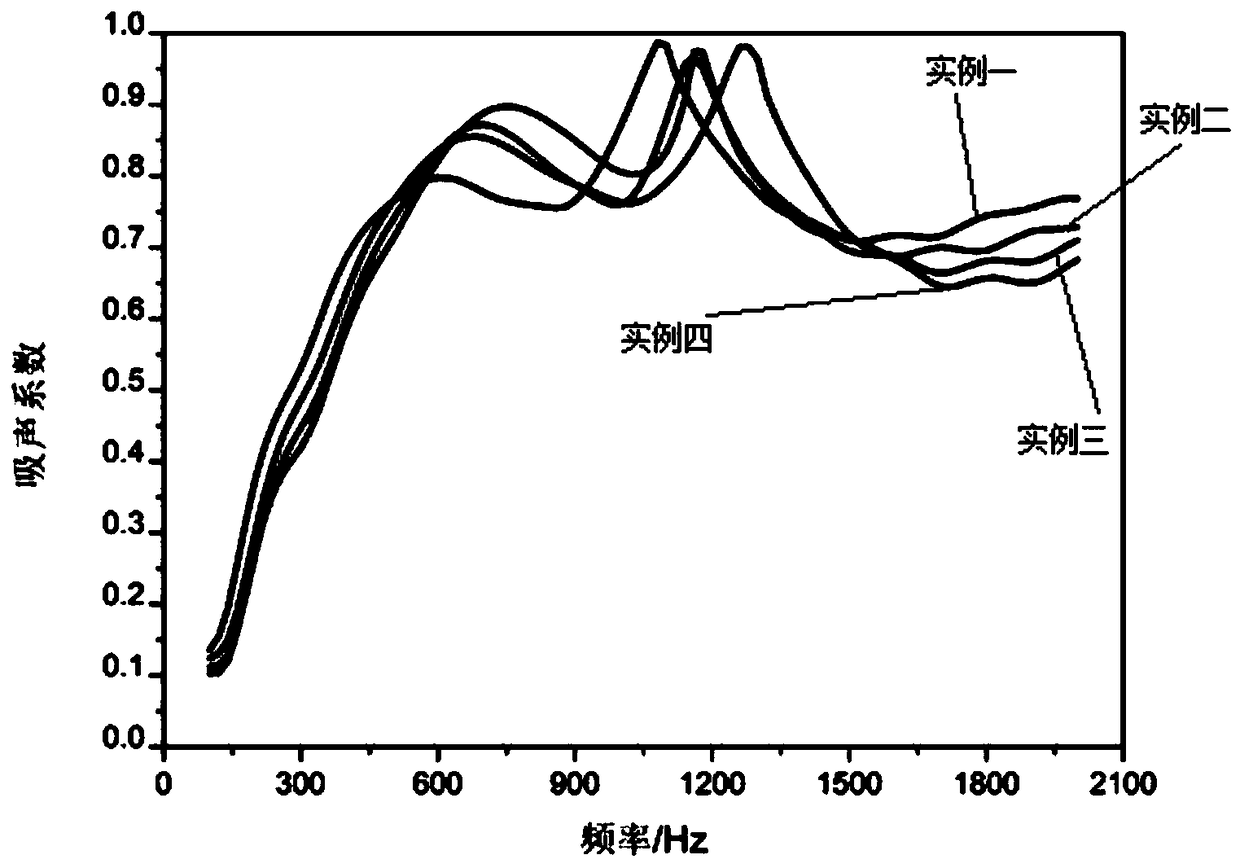

[0030] Embodiment 1: In this example, the material of the rigid perforated panel 2 and the rigid back plate 8 is aluminum. Wherein, the diameter of the through hole 3 on the rigid perforated panel 2 is 6mm, and the perforation rate is 18%. The porous material layer 4 is preferably melamine foam, with a thickness of 35mm, and the length of the rigid plate 7 of the winding structure is 13mm.

Embodiment 2

[0031] Embodiment 2: In this example, the material of the winding structure, the rigid perforated panel 2 and the rigid back plate 8 is aluminum. Wherein, the diameter of the through hole 3 on the rigid perforated panel 2 is 5mm, and the perforation rate is 14%. The porous material layer 4 is preferably melamine foam, with a thickness of 40mm, and the length of the rigid plate 7 of the winding structure is 17mm.

Embodiment 3

[0032] Embodiment 3: In this example, the material of the winding structure, the rigid perforated panel 2 and the rigid back plate 8 is aluminum. Wherein, the diameter of the through hole 3 on the rigid perforated panel 2 is 7 mm, and the perforation rate is 22%. The porous material layer 4 is preferably melamine foam, with a thickness of 35 mm, and the length of the rigid plate 7 of the winding structure is 15 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com