Method of automatically judging azimuth of burning seat based on CCD vision

An automatic judgment, azimuth and angle technology, applied in the field of CCD visual alignment, can solve the problems of low production efficiency, low target efficiency, inconvenient operation, etc., and achieve the effect of improving efficiency, reducing errors, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

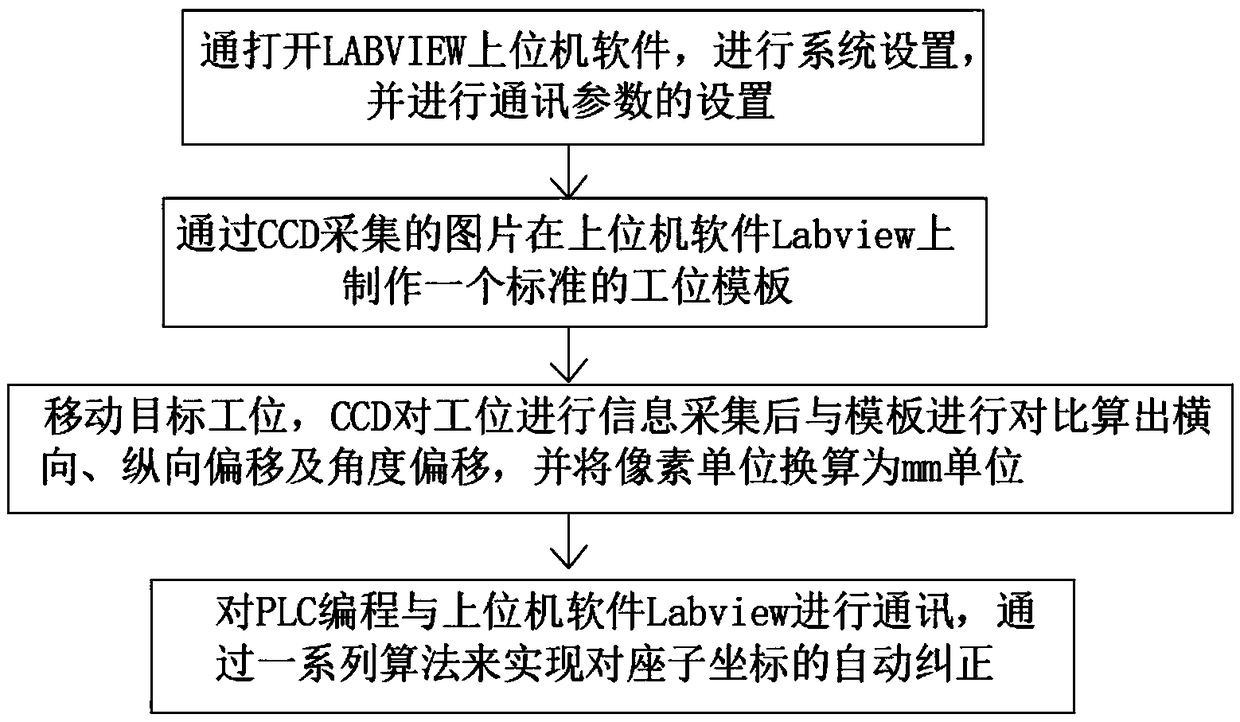

[0028] refer to Figure 1-3 , a method for automatically judging the azimuth angle of a programming seat based on CCD vision, is characterized in that, comprising the following steps:

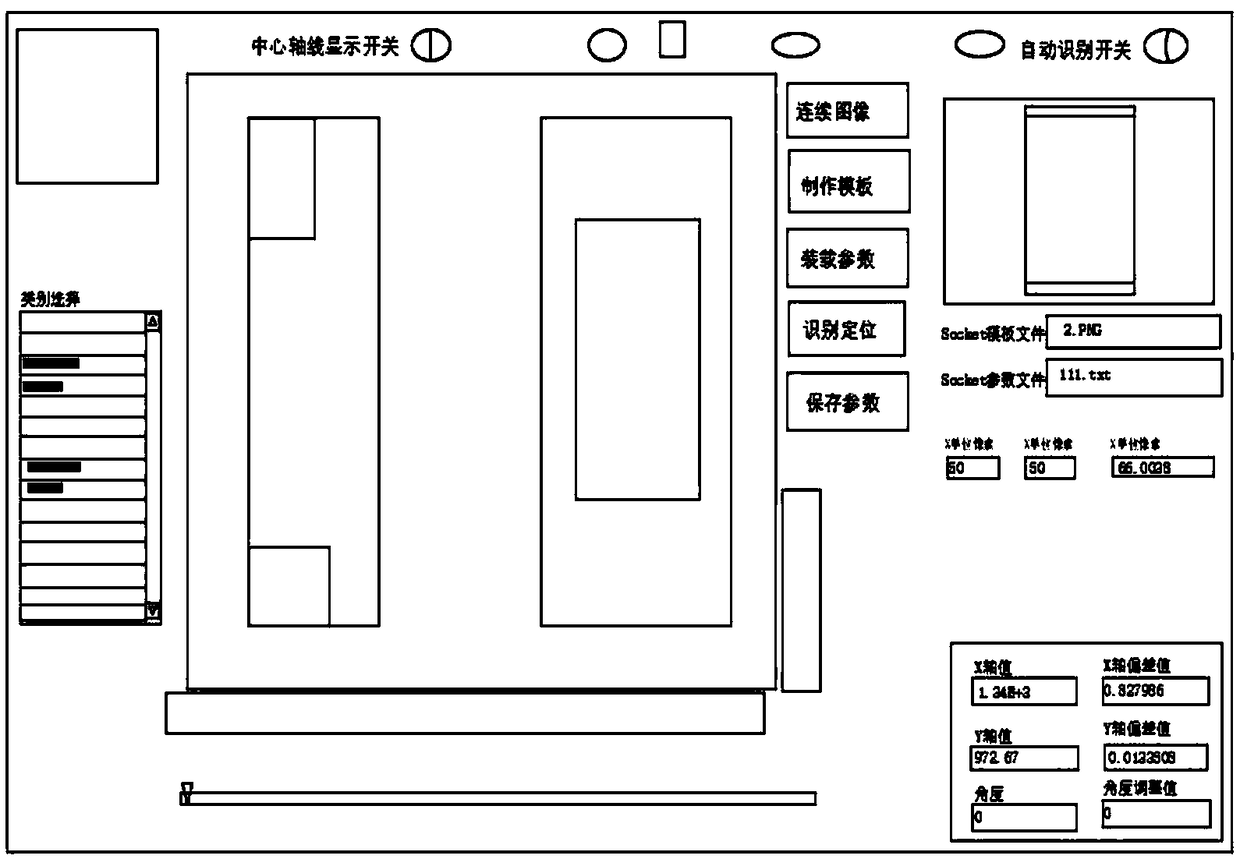

[0029] 1.1) Make a standard station template on the upper computer software Labview through the acquisition of CCD;

[0030] 1.2) The CCD collects the information of the station again and compares it with the template to calculate the lateral offset, and converts the pixel unit to mm;

[0031] 1.3) Communicate with the upper computer software Labview by programming the PLC, and obtain the information in step 1.2), and then realize the automatic correction of the seat coordinates through a series of algorithms in the PLC.

[0032] The making of standard station formwork in described step 1.1) comprises the following steps:

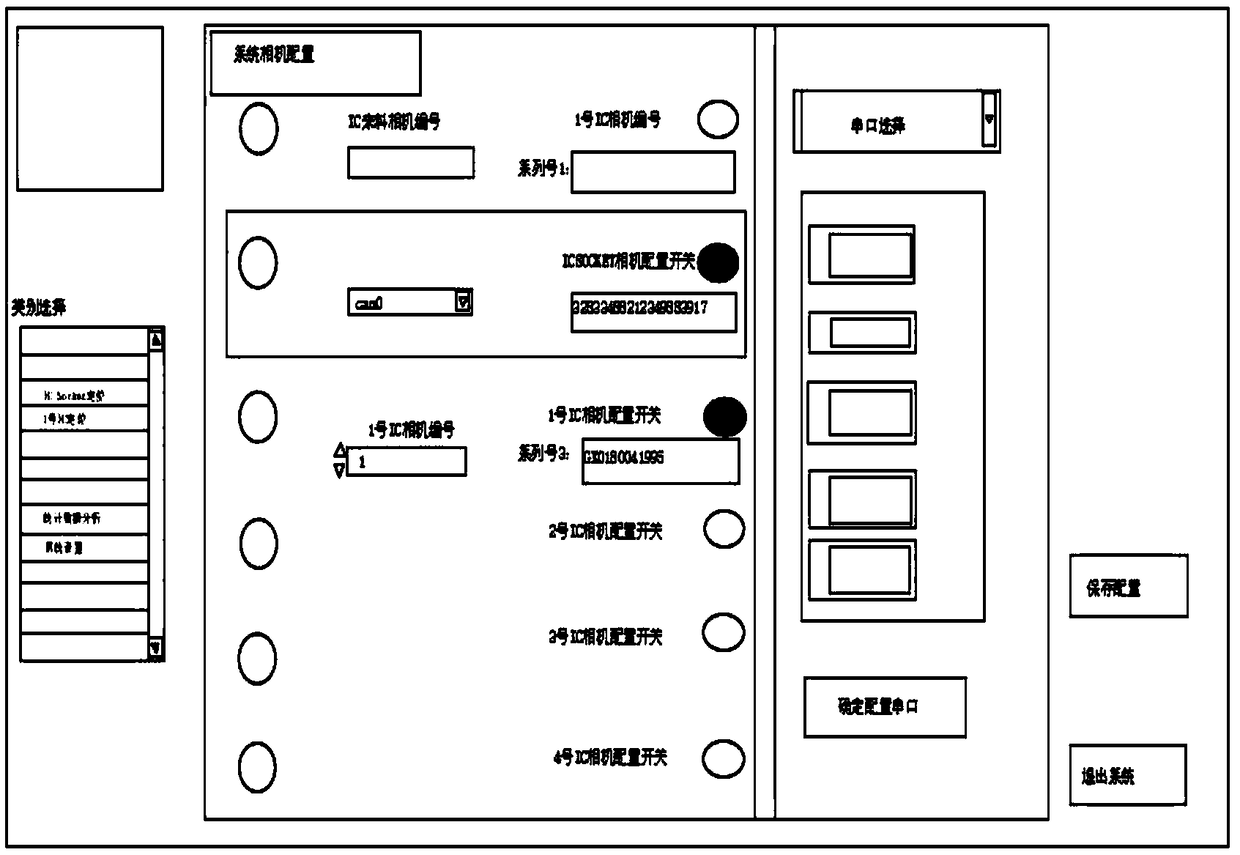

[0033] 2.1) First open the LABVIEW host computer software, click the system setting in the category selection, and configure the system camera;

[0034] 2.2) Turn on the ...

Embodiment 2

[0042] A method for automatically judging the azimuth angle of a burning seat based on CCD vision, is characterized in that, comprises the following steps:

[0043] 1.1) Make a standard station template on the upper computer software Labview through the acquisition of CCD;

[0044] 1.2) The CCD collects the information of the station again and compares it with the template to calculate the longitudinal offset, and converts the pixel unit to mm;

[0045] 1.3) Communicate with the upper computer software Labview by programming the PLC, and obtain the information in step 1.2), and then realize the automatic correction of the seat coordinates through a series of algorithms in the PLC.

[0046] The making of standard station formwork in described step 1.1) comprises the following steps:

[0047] 2.1) First open the LABVIEW host computer software, click the system setting in the category selection, and configure the system camera;

[0048] 2.2) Turn on the ICSocket camera configur...

Embodiment 3

[0056] A method for automatically judging the azimuth angle of a burning seat based on CCD vision, is characterized in that, comprises the following steps:

[0057] 1.1) Make a standard station template on the upper computer software Labview through the acquisition of CCD;

[0058] 1.2) The CCD collects the information of the station again and compares it with the template to calculate the angle offset, and converts the pixel unit into mm unit;

[0059] 1.3) Communicate with the upper computer software Labview by programming the PLC, and obtain the information in step 1.2), and then realize the automatic correction of the seat coordinates through a series of algorithms in the PLC.

[0060] The making of standard station formwork in described step 1.1) comprises the following steps:

[0061] 2.1) First open the LABVIEW host computer software, click the system setting in the category selection, and configure the system camera;

[0062] 2.2) Turn on the ICSocket camera configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com