Equipment for fully-automatically making spring rolls and method for fully-automatically making spring rolls

A fully automatic spring roll technology, applied in baking, dough processing, food science, etc., can solve the problems of low production efficiency, high manufacturing cost, and large labor cost, so as to improve the encapsulation efficiency, improve the yield rate, The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

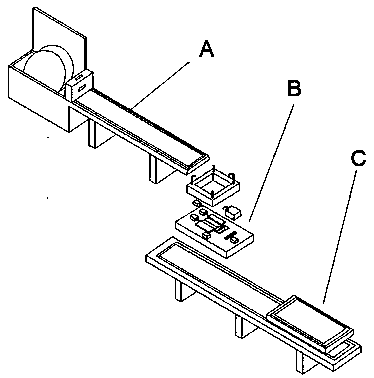

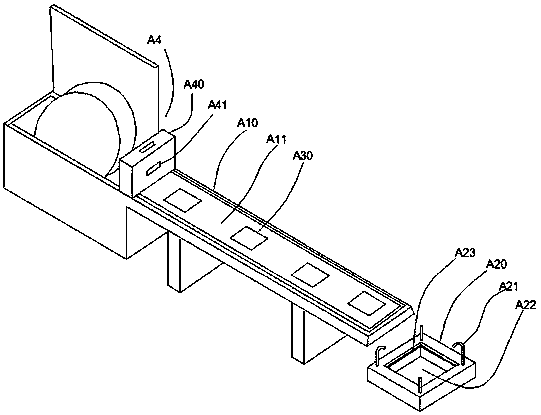

[0052] Such as figure 1 , figure 2 , Figure 4 , Figure 8 , Figure 10 Shown, a kind of spring roll full-automatic wrapping equipment comprises the skin making unit A4 that is used to make spring roll skin, and described skin making unit comprises spring roll skin making machine and skin cutting machine A40, and skin making machine and skin cutting machine are prior art, here Without going into too much detail, it also includes:

[0053] The spring roll skin delivery device A includes a spring roll skin delivery unit A10 and a peeling unit, the skin peeling unit includes a carrier platform A20 and an air jet unit A21, and the carrier platform is provided with a skin drop hole A22; the spring roll skin delivery unit The spring roll wrapper that is used for leather making unit manufacture is sent to the carrying platform, and described air injection unit is used for the spring roll wrapper A30 that is placed on the carrying platform and is blown down to the spring roll wra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com