Antifreeze foaming agent and preparation method thereof

A foaming agent and formula technology, applied in the field of antifreeze foaming agent and its preparation, can solve the problems of normal foaming and freezing of aqueous solution, and achieve the effect of reducing the possibility of freezing and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of antifreeze foaming agent, it is prepared by the following steps: ethylene glycol, glycerin, DMF, triethanolamine, PEO-PPO-PEO triblock copolymer (F127 type), polyoxyethylene castor oil and Mix and disperse evenly with deionized water, add sodium carboxymethylcellulose, c-NMF (cis-N-methylformamide) linear tetramer and metal organic framework material MOF-5, stir and disperse evenly to obtain a solution, Take the filtrate by filtration; raise the filtrate from room temperature to 90°C at a heating rate of 50°C / hr and keep it warm for 1.5hr, then cool it down to -60°C at a cooling rate of 50°C / hr and keep it warm for 1.5hr, then Make it warm up to room temperature at a heating rate of 50°C / hr and keep it warm for 1.5hr, then filter again, and the filtrate is an antifreeze foaming agent.

[0016] In terms of mass percent, this antifreeze foaming agent comprises the following components: 33% ethylene glycol, 3% glycerin, 3% DMF, 1.8% triethanolamine,...

Embodiment 2

[0017] Embodiment 2: a kind of antifreeze foaming agent, the difference with embodiment 1 is, by mass percentage, this kind of antifreeze foaming agent comprises following components: 33% ethylene glycol, 2% glycerin, 2% DMF, 1.5% triethanolamine, 0.08% sodium carboxymethylcellulose, 0.1% linear tetramer of c-NMF, 0.1% metal organic framework material MOF-5, 24% PEO-PPO - PEO triblock copolymer (type F127) and 5% polyoxyethylene castor oil, the balance being deionized water.

Embodiment 3

[0018] Embodiment 3: a kind of antifreeze foaming agent, the difference with embodiment 1 is, by mass percentage, this kind of antifreeze foaming agent comprises following components: 33% ethylene glycol, 4% glycerin, 4% DMF, 2.0% triethanolamine, 0.12% sodium carboxymethylcellulose, 0.2% linear tetramer of c-NMF, 0.2% metal organic framework material MOF-5, 27% PEO-PPO - PEO triblock copolymer (type F127) and 7% polyoxyethylene castor oil, the balance being deionized water.

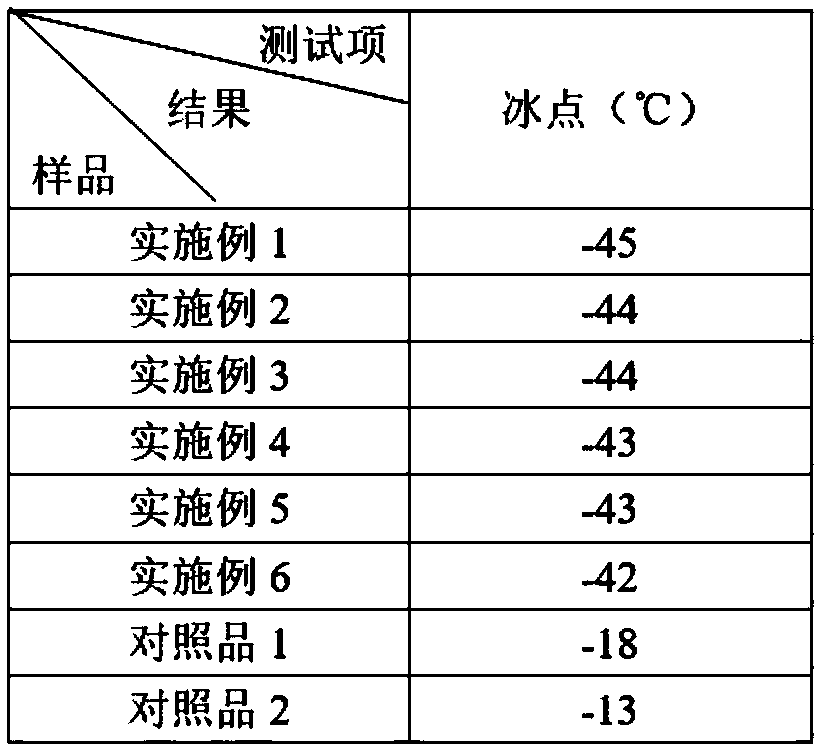

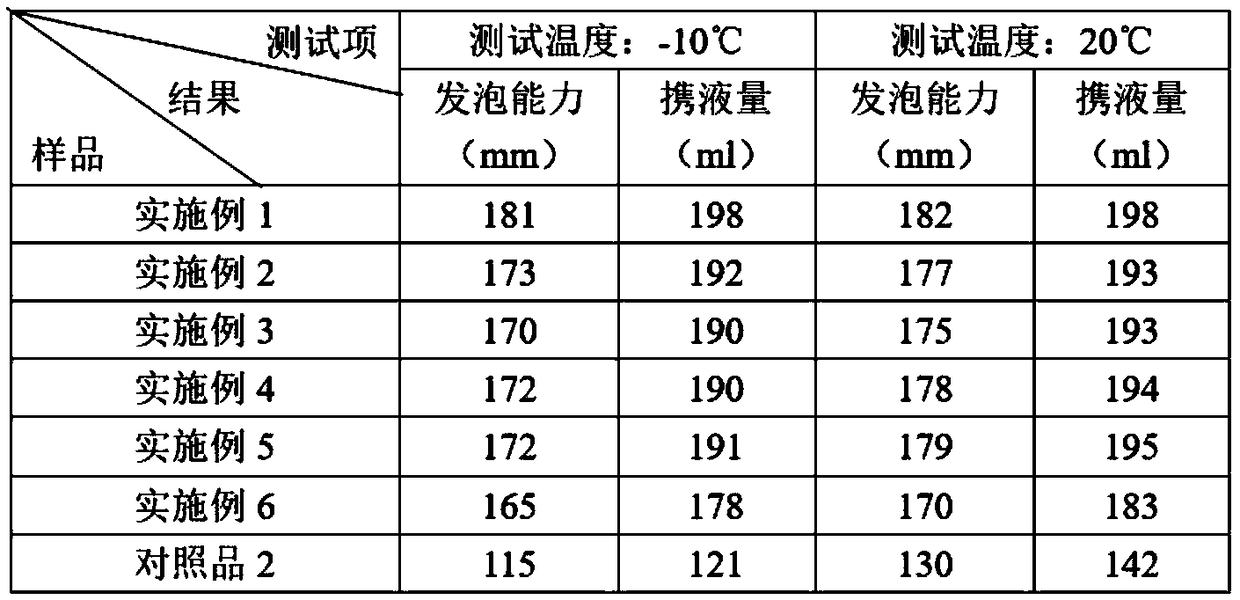

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com