Salt-storing deicing material special for asphalt pavement and preparation method thereof

A technology for asphalt pavement and salt storage, applied in the field of materials, can solve the problems of unsatisfactory deicing effect of snow-melting and deicing agent, shortening the service life of roads, and reducing road performance of pavement, so as to improve long-term deicing effect and good application effect. , the effect of delaying the freezing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

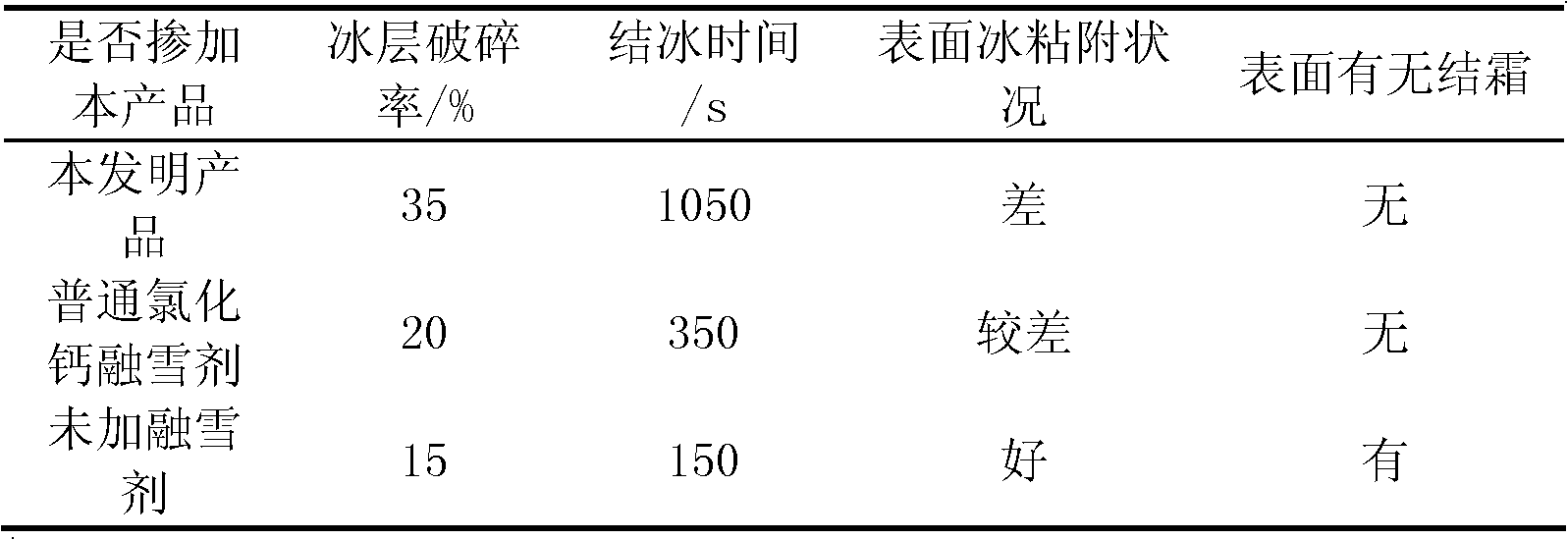

Embodiment 1

[0034] Take the production of 1000g of special deicing material for salt storage asphalt pavement as an example, the amount of each raw material is as follows (all components in the system are commercially available products):

[0035] Inorganic freezing point depression main agent: 400g;

[0036] Organic auxiliary freezing point depressant: 100g;

[0037] Freeze delay agent: 100g;

[0038] Ice softener: 100g;

[0039] Release stabilizer: 300g.

[0040] Anhydrous calcium chloride with a fineness of 20-200 mesh is selected as the main inorganic freezing point depressant.

[0041] The organic auxiliary freezing point depressant is composed of ethylene glycol and urea, and the mass ratio is ethylene glycol:urea=100:65; the freezing retarder is composed of sodium polyacrylate, maleic anhydride isobutylene polymer, and the mass ratio is Sodium polyacrylate: maleic anhydride isobutylene polymer=100:90; the ice layer softening agent is 1,6-hexanediol diacrylate; the release stabilizer is PO 42....

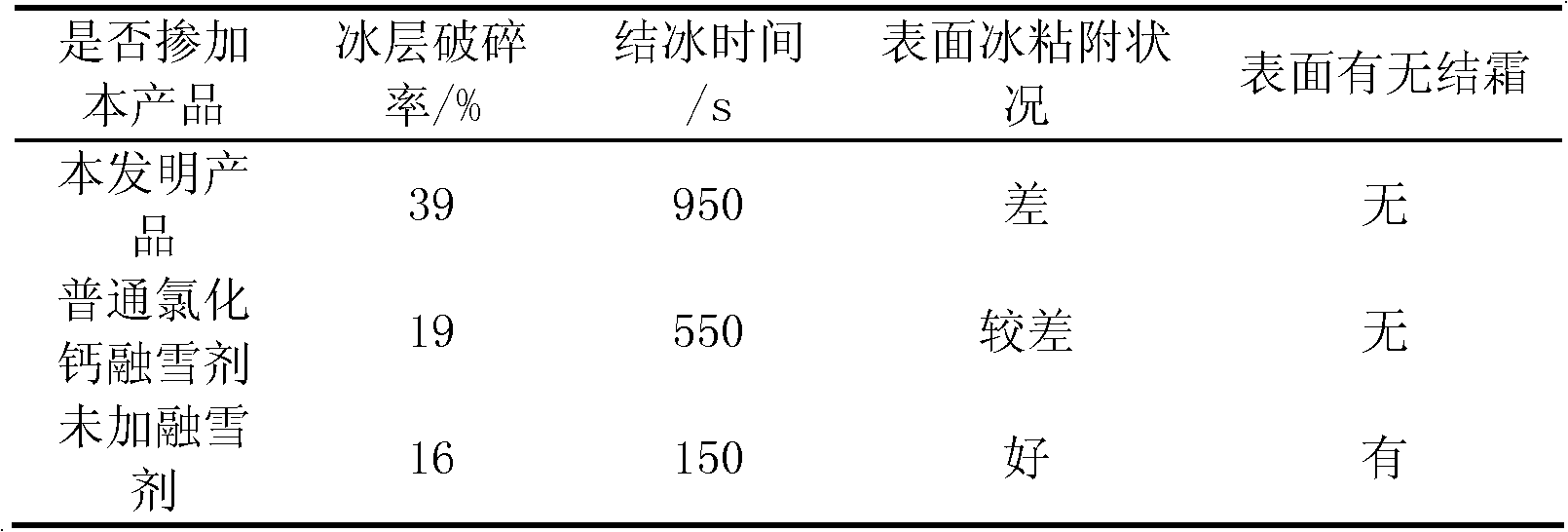

Embodiment 2

[0047] Take the production of 1000g of special deicing material for salt storage asphalt pavement as an example, the amount of each raw material is as follows (all components in the system are commercially available products):

[0048] Inorganic freezing point depression main agent: 400g;

[0049] Organic auxiliary freezing point depressant: 150g;

[0050] Freeze delay agent: 50g;

[0051] Ice softener: 50g;

[0052] Release stabilizer: 350g.

[0053] The inorganic freezing point depression main agent is calcium chloride with a fineness of 20-200 mesh.

[0054] The organic auxiliary freezing point depressant is composed of ethylene glycol; the freezing retarder is composed of sodium polyacrylate, maleic anhydride isobutylene polymer, and the mass ratio is sodium polyacrylate: maleic anhydride isobutylene polymer=100:120 The ice layer softening agent is 1,6-hexanediol diacrylate; the release stabilizer is PO 42.5 ordinary Portland cement and hydrated lime, and the mass ratio is ordinary P...

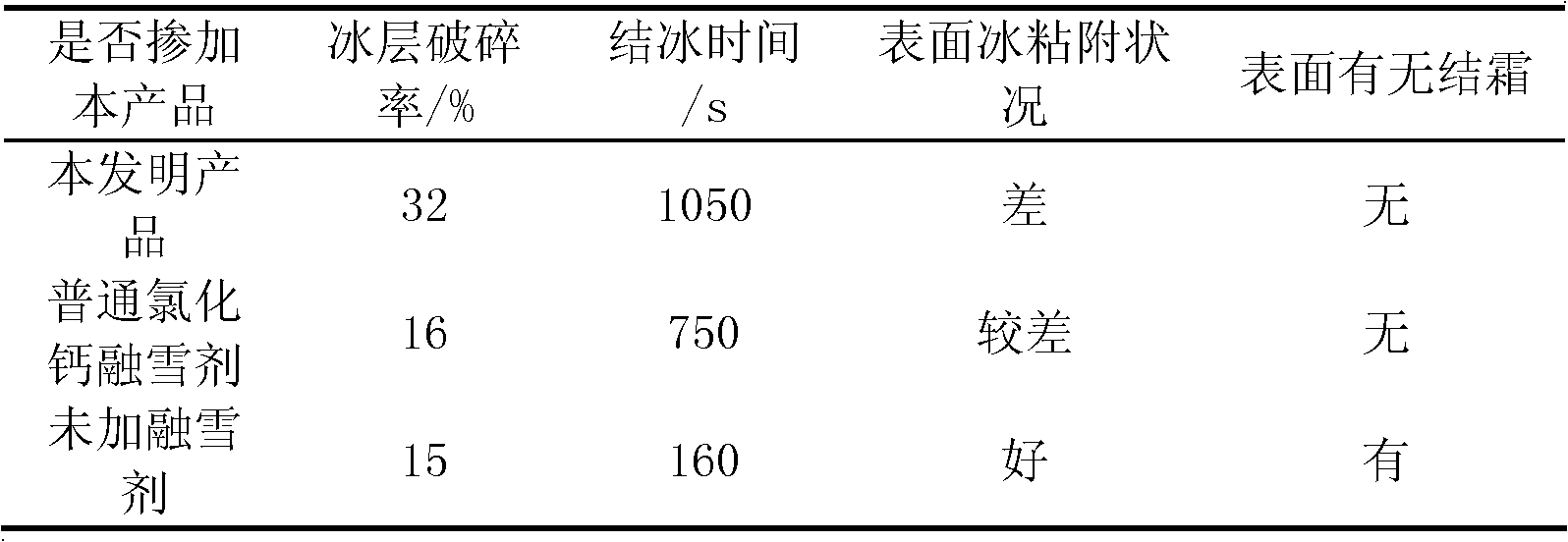

Embodiment 3

[0062] Take the production of 1000g of special deicing material for salt storage asphalt pavement as an example, the amount of each raw material is as follows (all components in the system are commercially available products):

[0063] Inorganic freezing point depression main agent: 300g;

[0064] Organic auxiliary freezing point depressant: 100g;

[0065] Freeze delay agent: 50g;

[0066] Ice softener: 50g;

[0067] Release stabilizer: 500g.

[0068] Anhydrous calcium chloride with a fineness of 20-200 mesh is selected as the main inorganic freezing point depressant.

[0069] The organic auxiliary freezing point depressant is composed of ethylene glycol and 1-2 propylene glycol, and the mass ratio is ethylene glycol: 1-2 propylene glycol=100:120; the freezing retarder is composed of sodium polyacrylate; the ice The layer softening agent is propylene glycol methyl ether acetate; the release stabilizer is PO 42.5 cement and slaked lime, and the mass ratio is cement: slaked lime=100:10.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com