Biological improver for black and odorous water bottom sludge

A biological modifier, black and odorous water technology, applied in the field of water treatment, can solve the problems of effective sludge utilization, difficult sludge treatment, secondary pollution, etc. The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

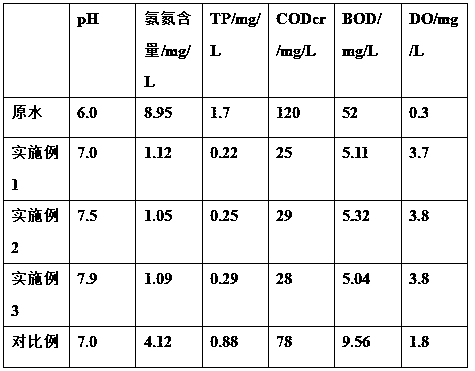

Embodiment 1

[0027] A bio-improving agent for black and odorous water bottom mud. The raw materials include 20 parts of modified diatomite, 10 parts of polyaluminum ferric sulfate, 10 parts of bentonite, 10 parts of chitosan, 10 parts of bamboo shoot shells, and 10 parts of bamboo shoot shells by weight. 8 parts of vitae alkali extract, 10 parts of microbial agent.

[0028] The preparation method of the modified diatomite is as follows: the diatomite is placed in a 5mol / L hydrochloric acid solution, stirred and mixed for 2-5 hours, then taken out and washed until neutral, and then the diatomite is calcined at 500°C for 1 hour , to obtain modified diatomite.

[0029] The preparation method of the bamboo shoot shells is as follows: crush the washed and dried bamboo shoot shells, sieve them, and dry them; then place them in 0.5mol·L -1 In the nitric acid solution, immerse at 50-70 ℃ for 2-4 h;

[0030] The preparation method of the vitex ash alkali extract is as follows: take the vitex bran...

Embodiment 2

[0036] A bio-improving agent for black and odorous water bottom mud, its raw materials include 22 parts of modified diatomite, 13 parts of polyaluminum ferric sulfate, 13 parts of bentonite, 13 parts of chitosan, 13 parts of bamboo shoot shells, 10 parts of vitae alkali extract, 13 parts of microbial agent.

[0037] The preparation method of the modified diatomite is as follows: the diatomite is placed in a 5mol / L hydrochloric acid solution, stirred and mixed for 2-5 hours, then taken out and washed until neutral, and then the diatomite is calcined at 500°C for 1 hour , to obtain modified diatomite.

[0038] The preparation method of the bamboo shoot shells is as follows: crush the washed and dried bamboo shoot shells, sieve them, and dry them; then place them in 0.5mol·L -1 In the nitric acid solution, immerse at 50-70 ℃ for 2-4 h;

[0039] The preparation method of the vitex ash alkali extract is as follows: take the vitex branches and leaves, cremate them into ashes, diss...

Embodiment 3

[0045] A bio-improving agent for black and odorous water bottom mud, the raw materials of which are calculated in parts by weight, including 25 parts of modified diatomite, 15 parts of polyaluminum ferric sulfate, 15 parts of bentonite, 15 parts of chitosan, 15 parts of bamboo shoot shells, 15 parts of vitae alkali extract, 15 parts of microbial agent.

[0046] The preparation method of the modified diatomite is as follows: the diatomite is placed in a 5 mol / L hydrochloric acid solution, stirred and mixed for 5 hours, then taken out and washed until neutral, and then calcined at 500° C. for 1 hour to obtain Modified diatomaceous earth.

[0047] The preparation method of the bamboo shoot shells is as follows: crush the washed and dried bamboo shoot shells, sieve them, and dry them; then place them in 0.5mol·L -1 In the nitric acid solution, immerse at 50-70 ℃ for 2-4 h;

[0048] The preparation method of the vitex ash alkali extract is as follows: take the vitex branches and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com