Method for preparing high-modulus water glass by using fly ash

A high modulus water glass, fly ash technology, applied in the direction of alkali metal silicate, silicate, etc., to achieve the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

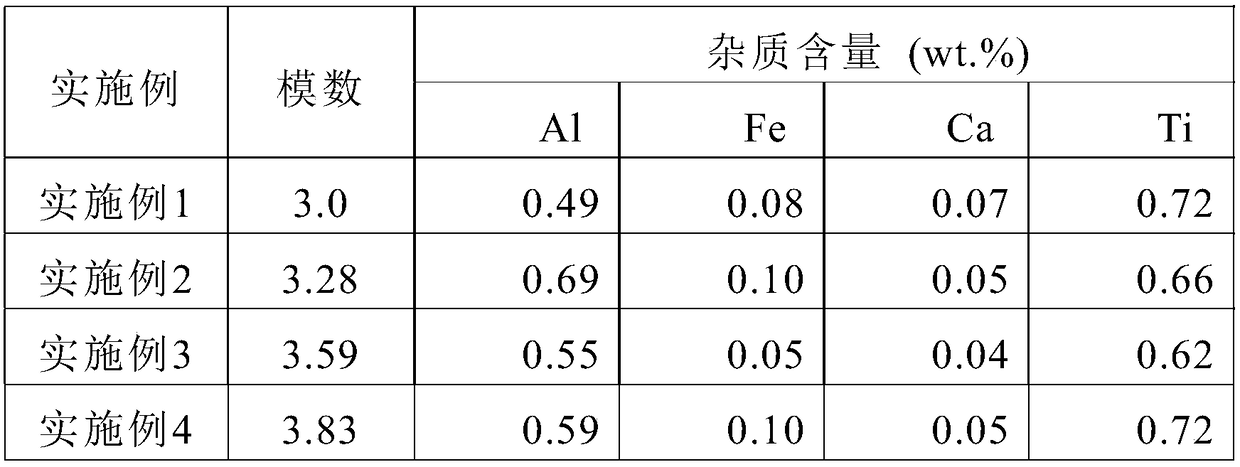

Examples

Embodiment 1

[0033] Mix fly ash with 20wt% sodium hydroxide solution, control the solid-to-liquid ratio of fly ash and sodium hydroxide to 1:3, react at 100°C for 2 hours, and filter and separate the obtained desiliconized ash with Fly ash and sodium hydroxide are mixed and ground according to the Na:Al:Si molar ratio of 0.8, and roasted at 850°C for 2h; the roasted product is mixed with 20wt.% hydrochloric acid according to the solid-to-liquid ratio of 1:4, and reacted at 90°C for 2h After the reaction, filter and wash with water to obtain acid leaching residue; mix acid leaching residue and desiliconization solution at a ratio of 1:4, react at 80°C for 2 hours, and filter to obtain high modulus water glass.

Embodiment 2

[0035] Mix fly ash with 20wt% sodium hydroxide solution, control the solid-to-liquid ratio of fly ash and sodium hydroxide to 1:4, react at 95°C for 3 hours, and filter and separate the obtained desiliconized ash with Fly ash and sodium hydroxide are mixed and ground according to the Na:Al:Si molar ratio of 1.0, and roasted at 850°C for 3h; the roasted product is mixed with 20wt% hydrochloric acid according to the solid-to-liquid ratio of 1:5, and reacted at 90°C for 3h, After the reaction, filter and wash with water to obtain acid leaching residue; mix acid leaching residue and desiliconization solution at a ratio of 1:3.5, react at 100°C for 1 hour, and filter to obtain high modulus water glass.

Embodiment 3

[0037] Mix fly ash with 20wt% sodium hydroxide solution, control the solid-to-liquid ratio of fly ash and sodium hydroxide to 1:4, react at 100°C for 2 hours, and filter and separate the obtained desiliconized ash with Fly ash and sodium carbonate were mixed and ground according to the Na:Al:Si molar ratio of 0.8, and roasted at 890°C for 2h; the roasted product was mixed with 20wt.% hydrochloric acid according to the solid-to-liquid ratio of 1:5, and reacted at 90°C for 2h, After the reaction, filter and wash with water to obtain acid leaching residue; mix acid leaching residue and desiliconization solution at a ratio of 1:3.2, react at 90°C for 1 hour, and filter to obtain high modulus water glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com