Open equipment for continuous growth of carbon nanomaterial and preparation method

A carbon nanomaterial and open technology, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of inability to realize graphene continuous production and limited production efficiency, so as to reduce product damage and improve production Efficiency and yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

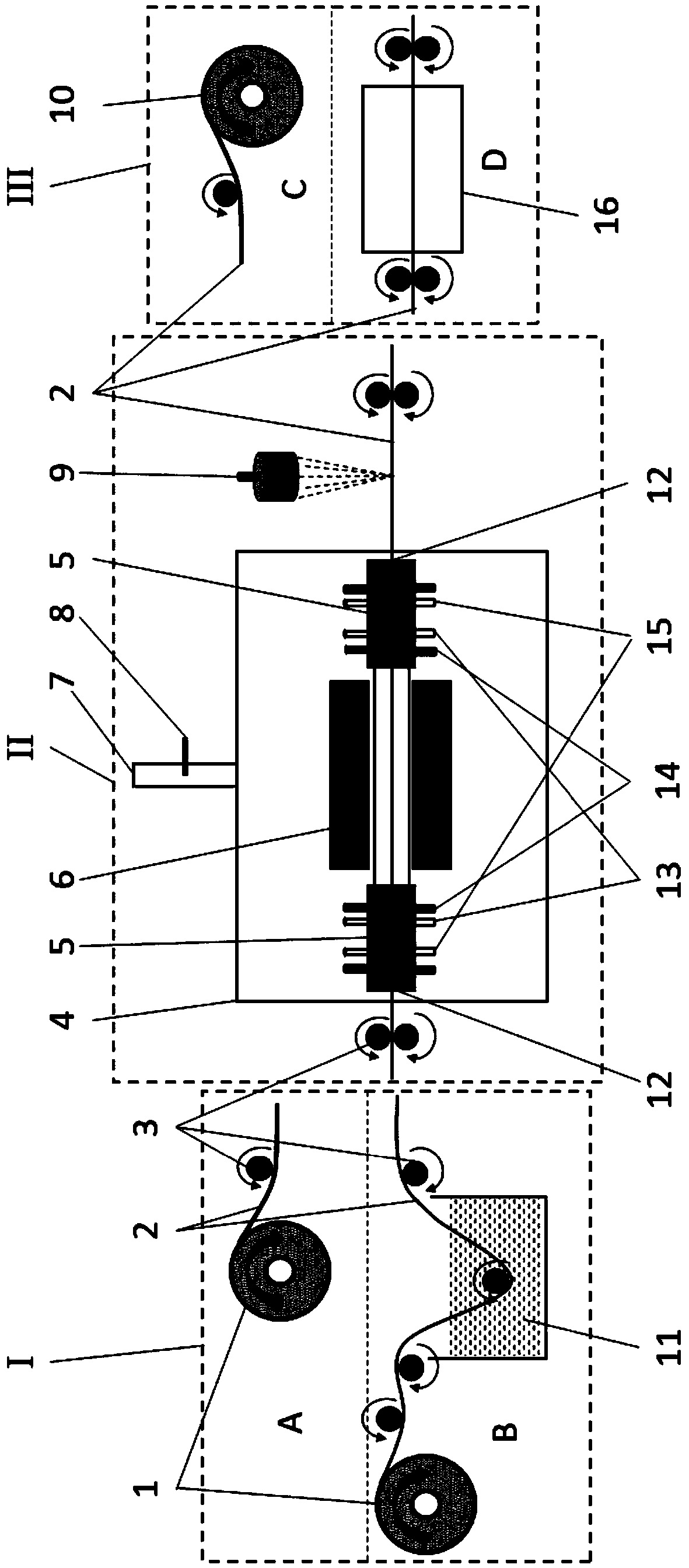

[0048] Such as figure 1 Shown, the present invention provides a kind of equipment of open type continuously growing carbon nanomaterials, comprises the metal foil band feeding system I, CVD system II and collection system III that are all in open gas; Metal foil band feeding system I is used The metal foil strip 2 is transported from the atmosphere to the CVD system II; the CVD system II is used to react to generate carbon nanomaterials, and the metal foil strip 2 enters the collection system III after attaching carbon nanomaterials in the CVD system II; wherein, the CVD system II Including CVD furnace 6 and control system (not shown in the figure), CVD furnace 6 is connected with control system signal, the entrance and exit of CVD furnace 6 are respectively sealed with a slit coupler 5, each slit coupler In the axial direction of 5, there is at least one slit 12 with one end connected to the CVD furnace 6 and the other end open to the atmosphere, and the slits 12 on the two s...

Embodiment 2

[0064]Provide below the method that adopts above-mentioned equipment to grow monolayer, continuous, high-quality graphene film on copper foil tape:

[0065] It should be noted that this method uses the simplest equipment. Metal foil belt feeding systems such as figure 1 As shown, the pretreatment system 11 is not included. The CVD system II is not equipped with an online quality monitoring system 9 , and the CVD furnace 6 is a vertical single-section quartz tube single heating furnace with a diameter of 25 mm and each slit coupler has only one slit 12 . Collection system III does not include aftertreatment system 16 . Both the carrier gas and the protective gas are argon, and the reaction gases are hydrogen and methane. The concentration of hydrogen and methane is diluted by argon to below the explosion limit. Of course, methane can also be replaced by ethane, acetylene, ethylene, (vaporized) alcohol etc. Unless otherwise specified, all gases are high-purity gases, which a...

Embodiment 3

[0078] This embodiment adopts the equipment described in embodiment one to grow a multilayer continuous graphene film on a nickel foil strip, and the difference from embodiment two is that:

[0079] 1. Metal foil strip 2 is nickel foil strip (11 mm wide, 25 μm thick, purity 99.9%).

[0080] 2. The conveying speed of the nickel foil belt is 300-600mm / min.

[0081] 3. The growth setting temperature range is 500-900°C, preferably 750-900°C. The higher the temperature, the faster the growth rate and the faster the conveying speed of the nickel foil belt. In the case of the same conveying speed, the slower the conveying speed of the nickel foil belt, the more layers of graphene; or in the case of constant conveying speed of the nickel foil belt, the higher the temperature, the more layers of graphene.

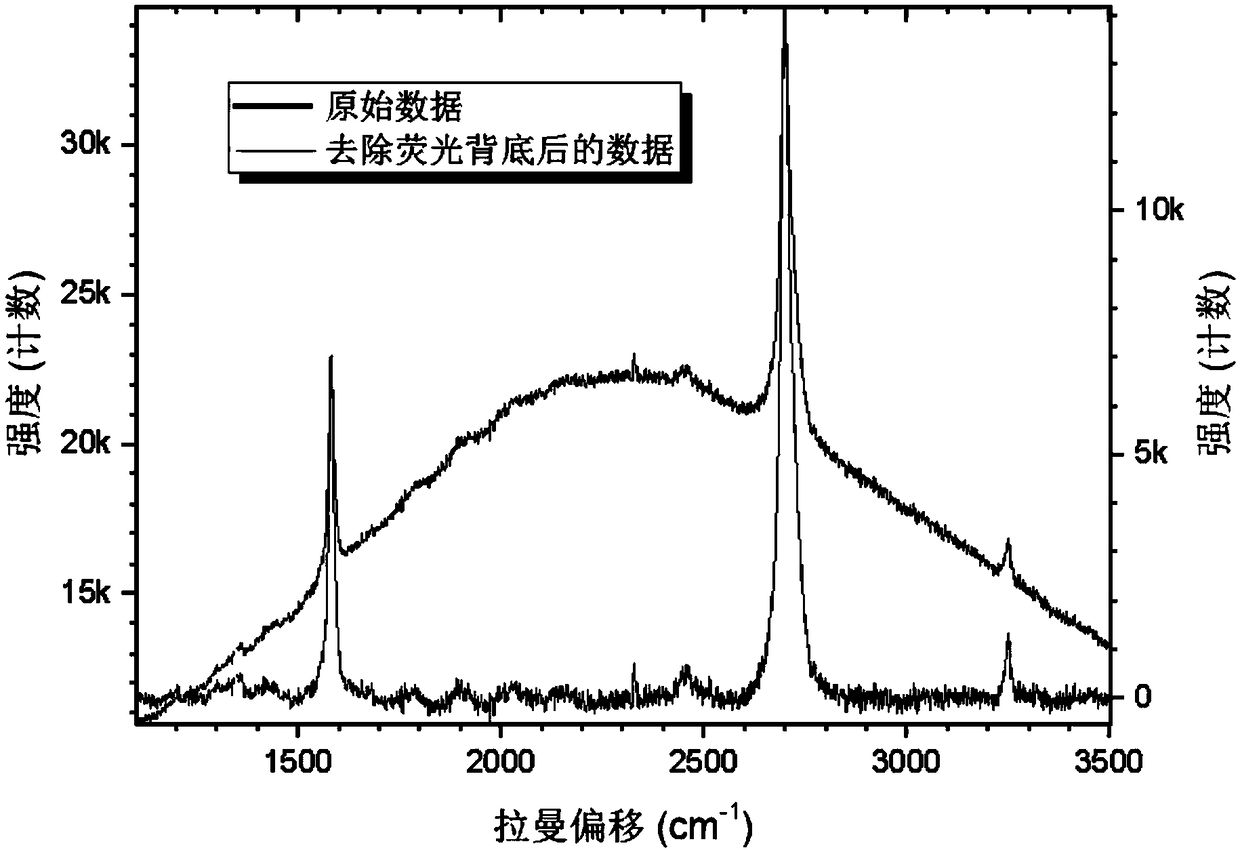

[0082] 4. For the results of laser Raman characterization, see Figure 7 ,Depend on Figure 7 It can be seen that the intensity of the 2D peak is lower than that of the G peak, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com