Process and system for preparing acid by combining sulfur and exhaust gas obtained in viscose exhaust gas TRS (total reduced sulfur) recovery

A waste gas and sulfur technology, applied in the direction of sulfur compounds, inorganic chemistry, non-metallic elements, etc., to reduce production costs, reduce waste gas emissions, and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

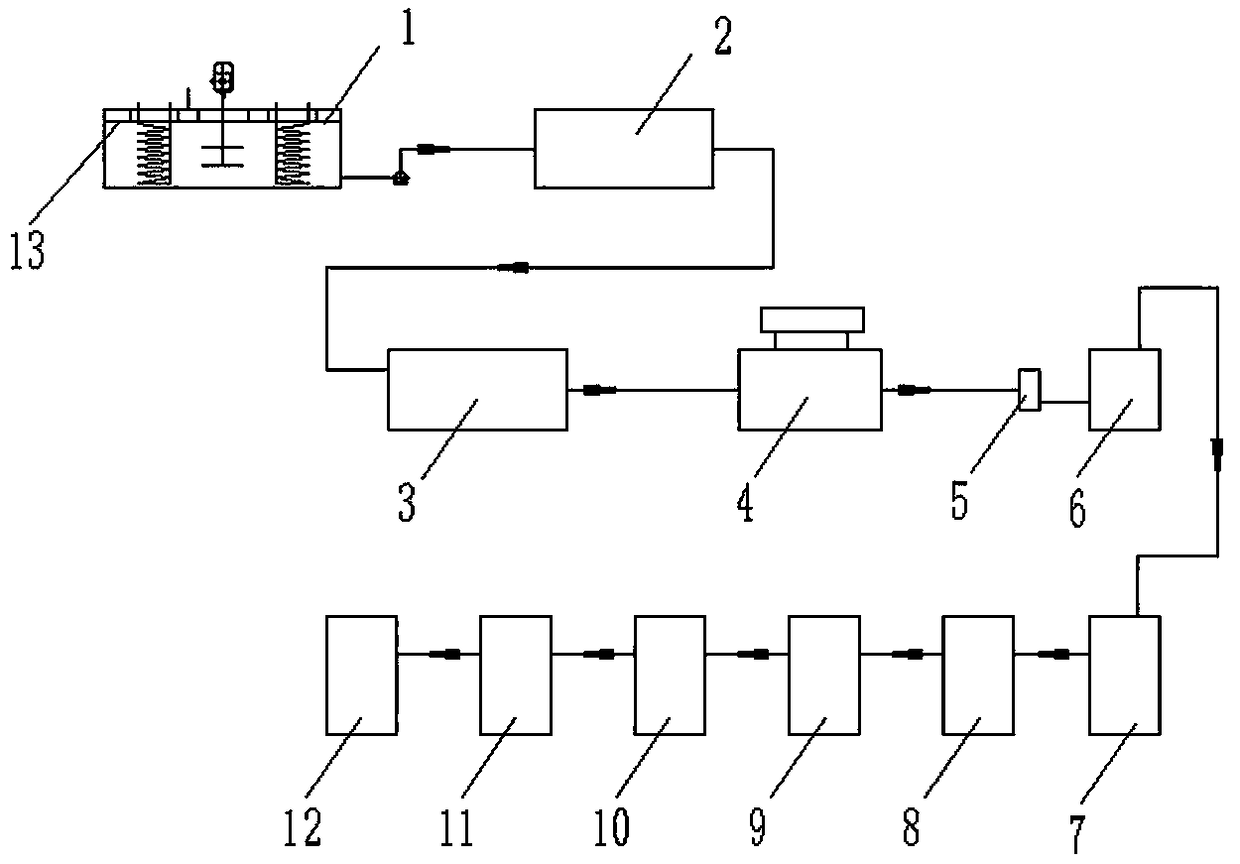

Image

Examples

Embodiment Construction

[0042] The viscose waste gas is passed into the TRS reactor to generate a slurry rich in complexing agent and sulfur, which enters the primary separation tank through the discharge port below, and the slurry and supernatant are separated by static separation. The bottom sauce is pumped to the primary centrifuge for dehydration and separation through the slurry pump, and the clear liquid above the primary separation tank is recovered to the TRS reactor through the pump.

[0043] After dehydration by a centrifuge, the TRS sulfur enters the primary washing tank, adding clean water, and under the combined action of stirring, one-time washing is realized. The mixed slurry enters the secondary separation tank, and the slurry is separated from the supernatant by static separation. The sauce at the bottom is pumped to the secondary centrifuge for dehydration and separation. The clear liquid above the secondary separation tank is recovered to the primary separation tank through the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com