Diamond wire winding method

A winding method and technology of diamond wire, which is applied in the field of diamond wire winding, can solve problems such as edge collapse, unstable single-point hooking, and diamond wire not reaching the edge of the I-shaped wheel, so as to avoid wire pressure and improve stability Sex, method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

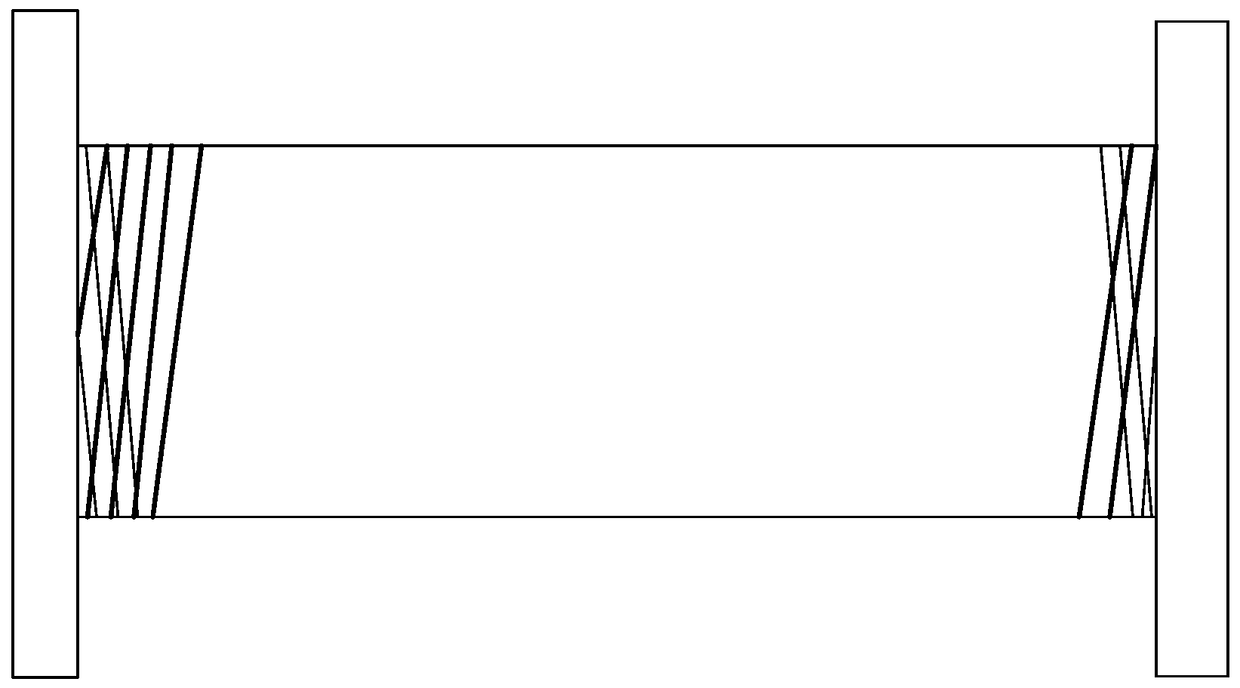

[0036] The winding method of the present invention comprises:

[0037] Step 1: Align the side of the I-shaped wheel, and determine the left and right edge positions of the cable;

[0038] The second step: the diamond wire wheel, using adhesive tape to bond the diamond wire to the middle cross section of the cylindrical surface of the I-shaped wheel;

[0039] Step 3: Start the winding device, set the speed of the winding shaft and the spacing of the wires, so that the spacing of the wires is stacked on the surface of the I-shaped wheel according to the set algorithm to produce a stable finished product;

[0040] Step 4: Shut down at fixed length, reach the preset product length, shut down, inspect and pack for shipment.

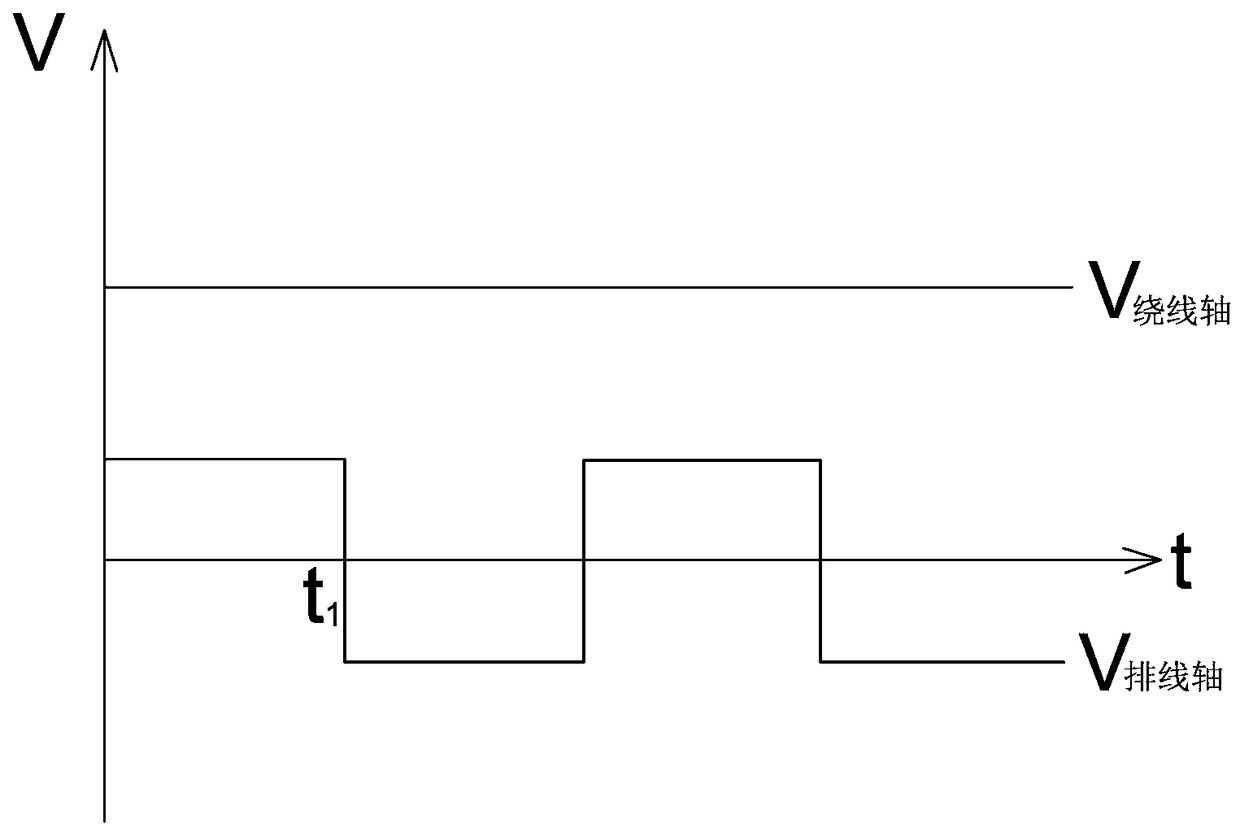

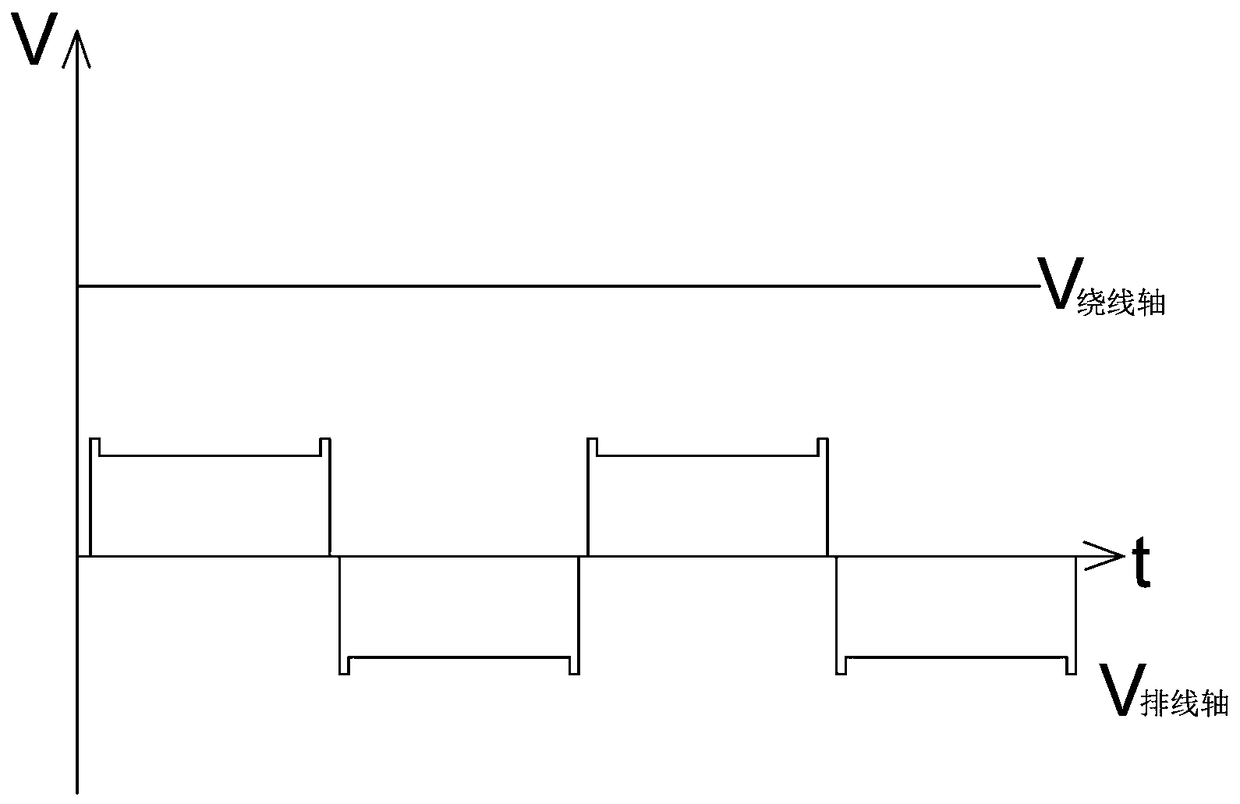

[0041] Among them, in the third step, the specific steps of setting the speed of the winding shaft and the speed of the winding shaft are as follows.

[0042] image 3 A schematic diagram of the relationship between the speed of the winding shaft and the sp...

Embodiment approach

[0043] As an embodiment of the present invention, the speed of the winding shaft can be set at 10-30 m / min. As a specific embodiment of the present invention, the length and diameter of the I-shaped wheel are 200mm, the speed of the winding shaft is 10m / min, and when the diamond wire spacing is 0.1mm, the speed of the third stage in the forward direction is 1.6 / 10000 of the speed of the winding shaft , the forward third-stage speed is 1.6mm / min, the forward second-stage speed and the forward fourth-stage speed are 2.4mm / min (1.5 times the forward third-stage speed), and the forward The maintenance time of the first stage speed is 1.8s, and the maintenance time of the forward second stage speed and the forward fourth stage speed is 1.8s. The calculation relationship is shown in Table 1.

[0044] Table 1 Speed relationship between the winding shaft and the winding shaft

[0045]

[0046] The winding mode of the diamond wire obtained according to the above-mentioned windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com