Retractable and unwinding device for fiber optic cable

A cable arrangement, fiber optic cable technology, applied in the directions of optics, light guides, optical components, etc., can solve the problems that the cables are not arranged to the side, overlap, and the winding speed is low, so as to reduce the installation area and facilitate the Installation and use, the effect of high quality wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

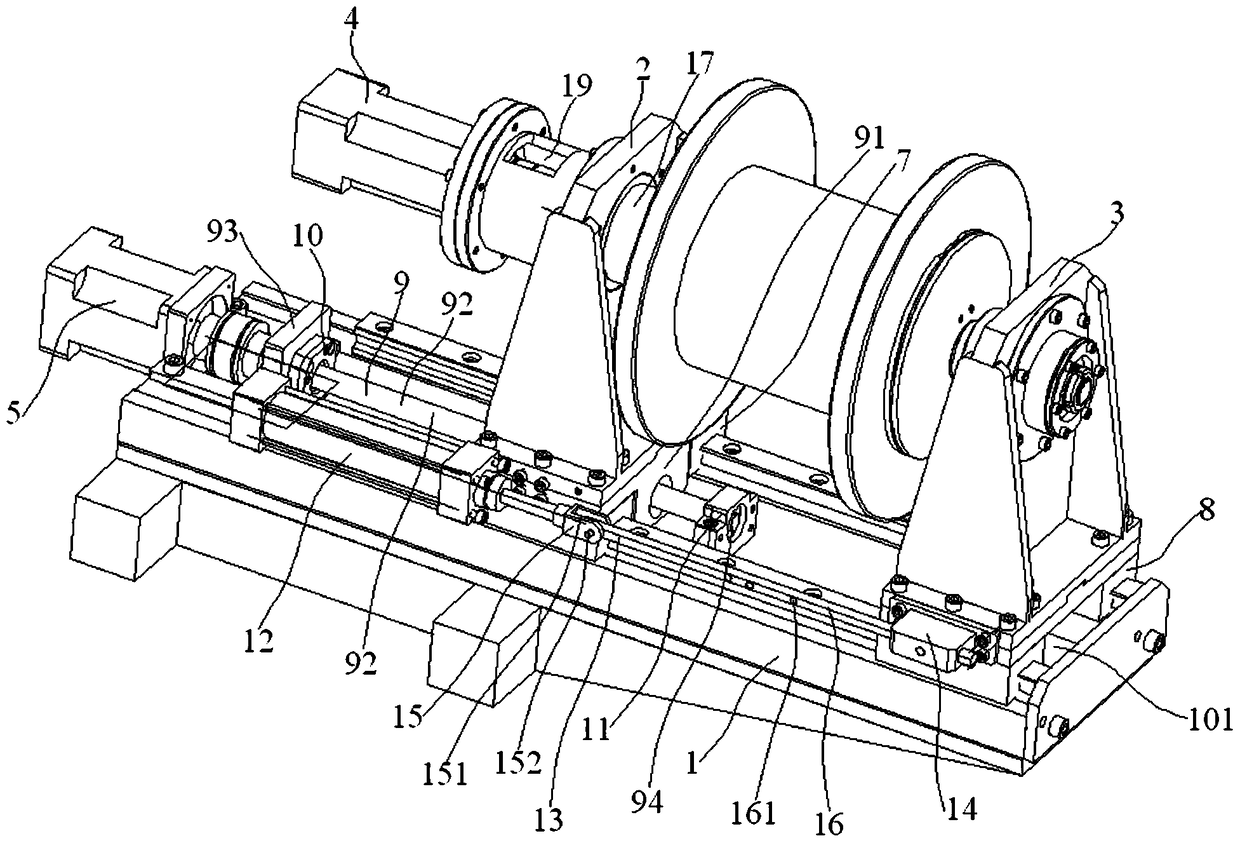

[0023] Embodiment 1: A retractable and arranging device for optical fiber cables, including: a base 1 with a groove 101, left and right support seats 2, 3, a rotating motor 4 and a traveling motor 5, the base 1 is located in the concave Two x-direction rails 6 are fixed on the surfaces on both sides of the groove 101, the first x-direction sliders 7 are fixed on both sides of the lower surface of the left support seat 2, and the second x-direction sliders 7 are fixed on both sides of the lower surface of the right support seat 3. The slider 8, the x-direction rail 6 is sequentially embedded in the respective grooves of the first x-direction slider 7 and the second x-direction slider 8;

[0024] An x-direction drive mechanism 9 located between two x-direction line rails 6 is installed in the groove 101 of the base 1 and located under the left and right support seats 2, 3, and the x-direction drive mechanism 9 includes an x-direction nut 91. The x-direction lead screw 92 embedde...

Embodiment 2

[0031] Embodiment 2: A retractable and arranging device for optical fiber cables, including: a base 1 with a groove 101, left and right support seats 2, 3, a rotating motor 4 and a traveling motor 5, the base 1 is located in the concave Two x-direction rails 6 are fixed on the surfaces on both sides of the groove 101, the first x-direction sliders 7 are fixed on both sides of the lower surface of the left support seat 2, and the second x-direction sliders 7 are fixed on both sides of the lower surface of the right support seat 3. The slider 8, the x-direction rail 6 is sequentially embedded in the respective grooves of the first x-direction slider 7 and the second x-direction slider 8;

[0032] An x-direction drive mechanism 9 located between two x-direction line rails 6 is installed in the groove 101 of the base 1 and located under the left and right support seats 2, 3, and the x-direction drive mechanism 9 includes an x-direction nut 91. The x-direction lead screw 92 embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com