Automatic horizontal left-and-right reciprocating take-up

A wire take-up device and horizontal reciprocating technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems that affect the quality of wire arrangement and the quality of wire arrangement is difficult to guarantee, and achieve the improvement of wire arrangement quality, The effect of reducing manual intervention and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

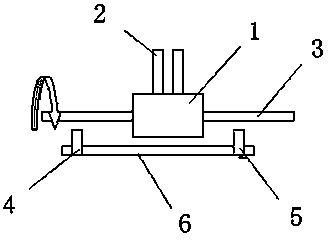

[0010] An automatic left and right horizontal reciprocating wire take-up device, including a flat wire guide 1 and a wire reel 2, the flat wire guide is installed on the transmission rod 3, when the transmission rod rotates, the flat wire guide moves axially along the transmission rod, and the transmission rod Connected to the motor through a chain. The wire reel is arranged on the flat wire guide, and the wire reel moves together with the flat wire guide. A left limiter 4 and a right limiter 5 for limiting the moving position of the flat wire guide are respectively provided on one side of the transmission rod and at two ends. A support rod 6 is arranged on one side of the transmission rod, and a left limiter and a right limiter are respectively arranged at two ends of the support rod.

[0011] A gear set capable of forward and reverse rotation is arranged in the flat wire guide. The speed of the flat wire guider moving horizontally and horizontally along the axis of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com