Shaft sleeve oil groove machining lathe

A technology for processing machine tools and processing mechanisms, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., and can solve the problems of difficult tool stroke control, increased costs, and high requirements for workers' manipulation skills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

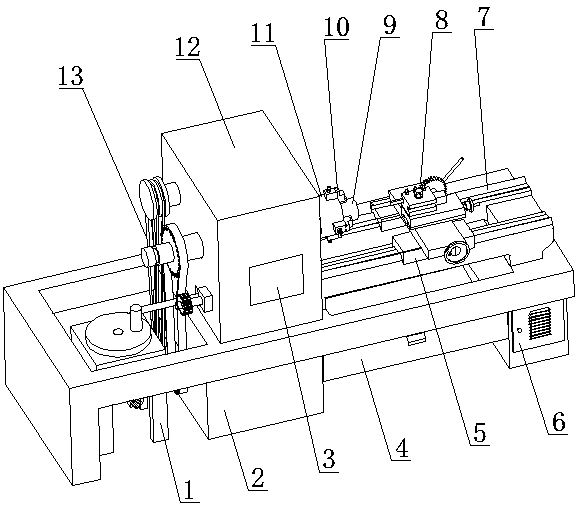

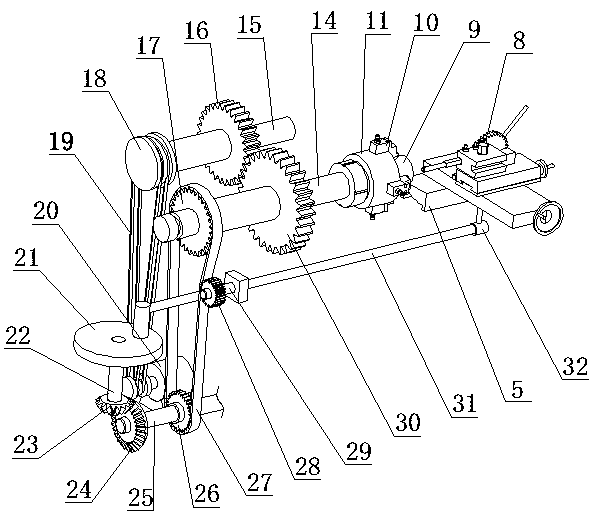

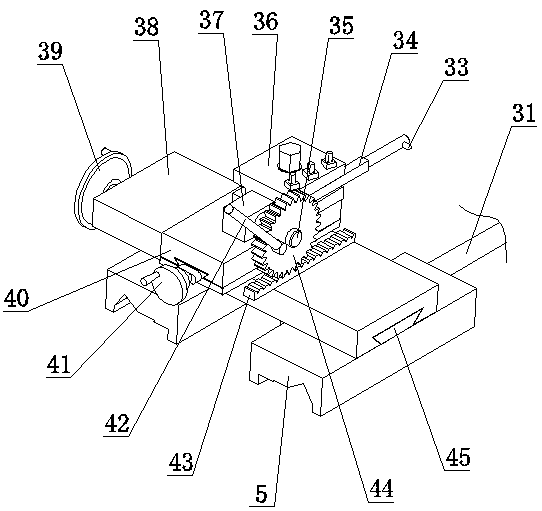

[0020] refer to Figure 1 to Figure 4 A shaft sleeve oil groove processing machine tool of the present invention will be further described.

[0021] A shaft sleeve oil groove processing machine tool, comprising a frame 2, a headstock 12, a guide rail 7, a transmission mechanism 13, and an oil groove processing mechanism 8, the headstock 12 is located above the frame 2, and an operation panel 3 is arranged on the front thereof, Described guide rail 7 is arranged on the right side of main shaft box 12, and its below is provided with waste box 4, and the right end of described frame 2 is provided with storage box 6, and described transmission mechanism 13 comprises motor 20, driven shaft one 15 , main shaft 14, driving shaft 25, driven shaft two 22, swing bar 31, the left end of described motor 20, driven shaft one 15 is all provided with pulley 18, and the outside of described pulley 18 is provided with belt 19, and described from Drive gear one 16 is provided in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com