Conveniently and rapidly used tool capable of twisting reinforcing steel bars to be in braided shape automatically

A twist-shaped, steel bar technology, applied in the field of machining, can solve the problems of inconvenient portability and difficulty in finding equipment, and achieve the effect of convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

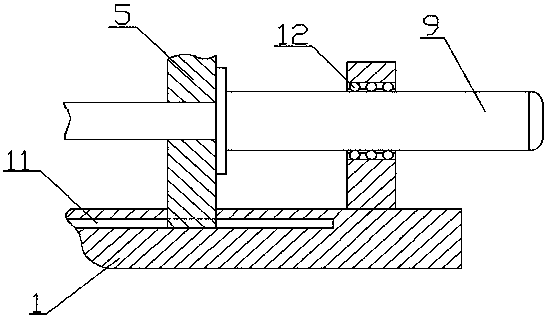

[0023] Now do further detailed explanation in conjunction with accompanying drawing.

[0024] As shown in the figure, a convenient tool for automatically twisting steel bars into a twist shape according to the present invention includes: a base 1, a chute 11, a rolling bearing 12, a motor 2, an adjustment device 3, an adjustment plate 31, a groove 32, a turbine 4, Steel bar trough 41, bearing 42, movable plate 5, discharge trough 51, lock buckle 52, pressing device 6, hydraulic block 61, lock buckle hole 62, traction device 7, traction groove 71, traction wheel 72, fixed pulley 73, Charging tray 8, telescopic rod 9.

[0025] There are support blocks on both sides of the base 1, and two chute 11 are arranged between the two support plates; the movable plate 5 is installed in the chute 11 on both sides; the turbine 4 is installed in the right The support block is used to drive the rotation of the steel bar; the telescopic rod 9 is installed on the movable plate 5 to limit the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com