Drug bottle transfer method and transfer system

A medicine bottle and flask machine technology, applied in the direction of sorting, etc., can solve the problems of increasing circulation cost, reducing circulation efficiency, and small number of bottlings, so as to increase circulation volume, improve circulation efficiency, improve production efficiency and produce qualified products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

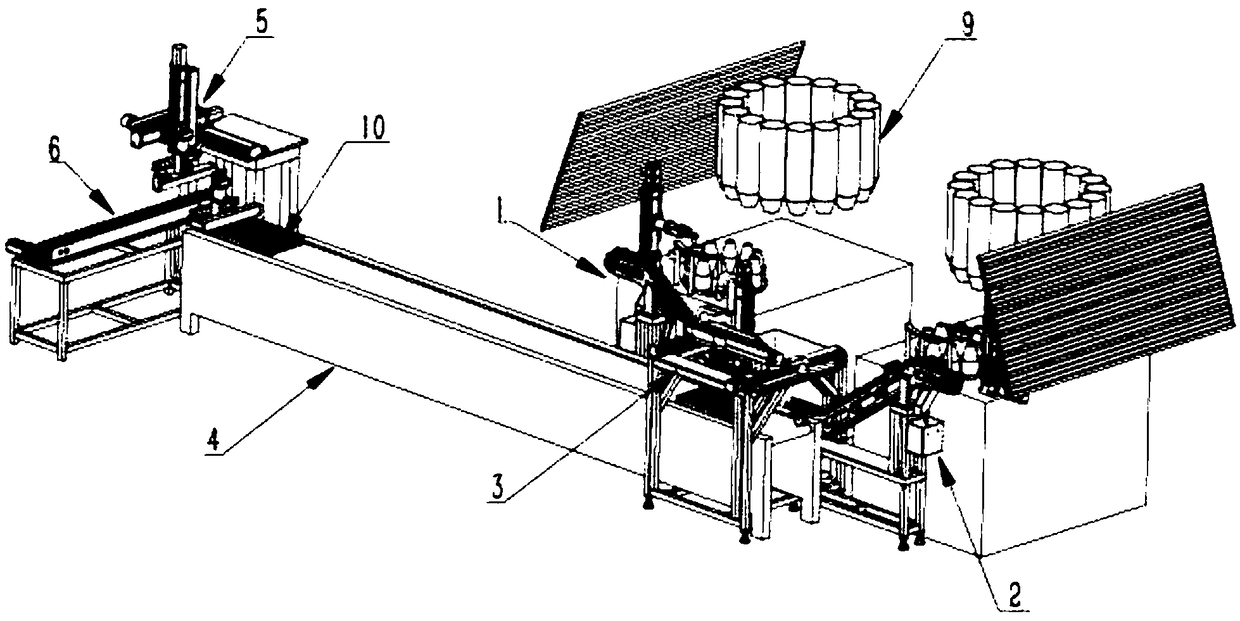

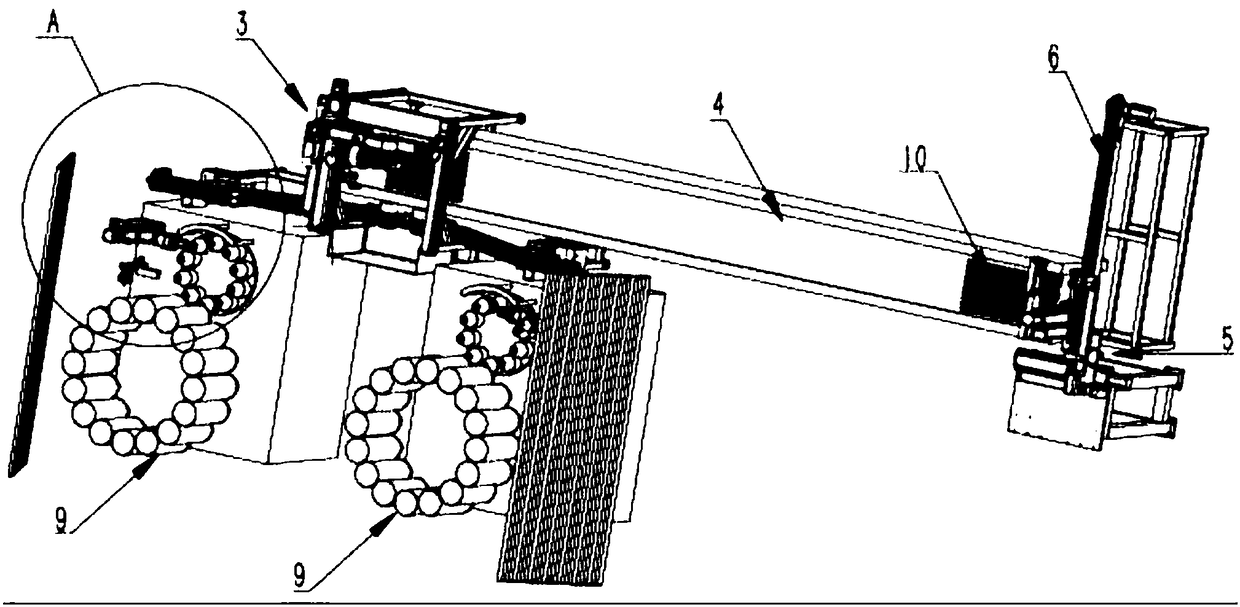

[0046] Such as Figure 1 to Figure 4 Shown, a kind of medicine bottle circulation method comprises the steps:

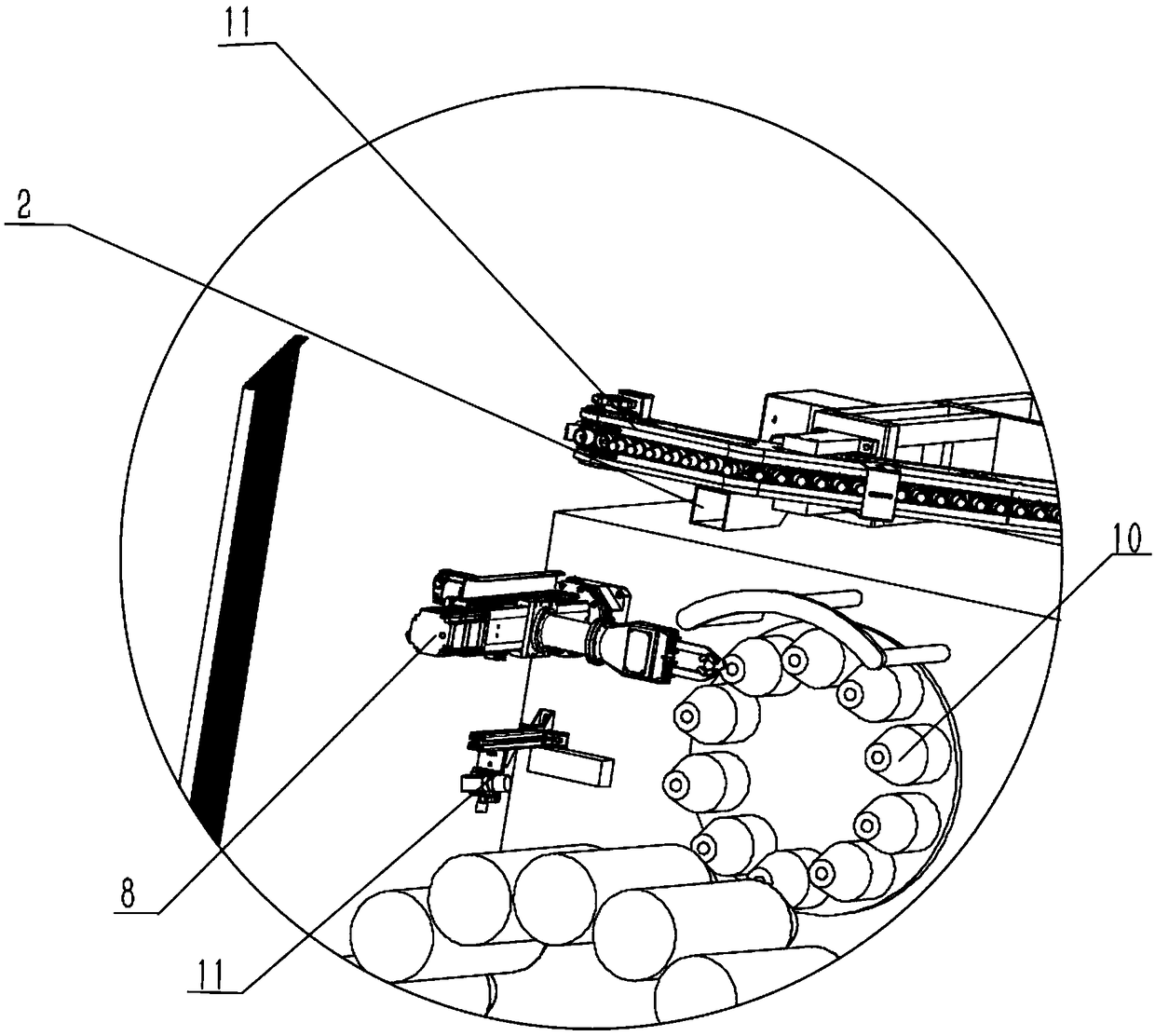

[0047] 1) The camera 11 shoots the medicine bottles 6 burned on the flask machine 9 one by one, and the camera transmits the captured data to the controller (not shown);

[0048] 2) The controller identifies the quality and transmits the quality result to the first manipulator 8;

[0049] 3) The first manipulator 8 performs screening according to the received quality results. If the quality is qualified, the first manipulator 8 clamps the medicine bottle above the first conveying device 1 and buckles it upside down on the first conveying device 1; The medicine bottle is clamped into the waste bottle frame 2;

[0050] 4) Use the first robot 3 to remove a row of medicine bottles from the downstream of the first conveying device 1, and place the medicine bottles vertically in a row on the upstream of the second conveying device 4, the specific steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com